Myron L 595 User Manual

Page 3

C.

Wiring

NOTE:

11

5 VAC systems — proceed to Section C.4

below.

1.

For 2

30 VAC systems: remove four screws in base

plate and lift out entire transformer electronics

assembly.

2.

If it is permissible for power line to share same opening

as valve and Controlstik sensor cables, this is easiest

method. If the 2

30 VAC power line must be separate,

CAREFULLY cut the edges of the preferred “knockout”

with a sharp knife to remove. The power line should

then be attached to the two transformer leads with wire

nuts. Be certain to also attach earth to the screw on the

side of the transformer.

3.

Return transformer electronics assembly to box and

screw down baseplate.

4.

Insert Controlstik cable through the slotted plastic plus

in box side. Connect the four color coded wires to the

terminals marked CONTROLSTIK.

5.

Obtain enough low voltage wire (at least 20 gauge/

.9398

mm diameter) to connect solenoid valve to

Transformer Box. Use pliers to attach spade lugs

(provided) to wire. Connect lugs to terminal strip

screws in box marked VALVE as in diagram.

6.

Recheck to be certain all connections are to correct

terminals.

CAUTION:

DO NOT short or connect the Controlstik

(sensor) to the terminals marked VALVE;

damage may result.

D.

Testing

1.

If controlling ordinary tap water, make sure Transformer

Box range toggle switch is set on “Hl” (toward back of

box). If controlling purified (such as deionized) water,

switch should be forward in “LO” position. Also,

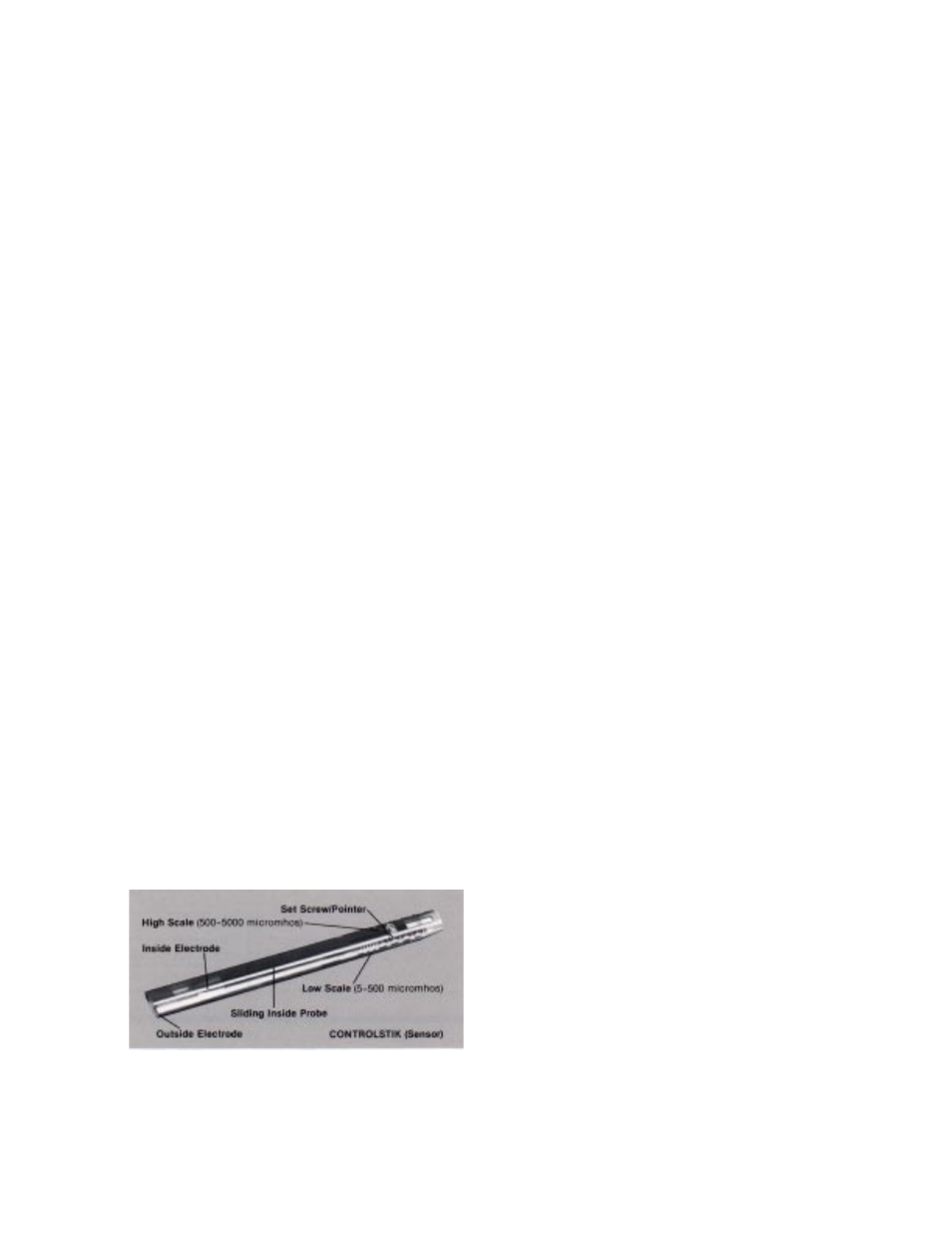

Controlstik sensor pointer should face in direction of

High (500-5000

micromhos) or Low (5-500) scale to

agree with Box range switch setting. To change pointer

loosen set screw with 9/64 inch Allen wrench. Turn

pointer to opposite scale. Lift the rod to the other side

of the set screw and place back under the wide part of

the pointer plate. Retighten set screw with fingers,

allowing inside probe to move within sheath.

2.

Turn on the power by connecting the transformer box to

1

15 Volt AC (or correct voltage for model being

installed). POWER light on Transformer Box will glow.

to “short” the inside cone electrode to the outside band

electrode. This “short” will turn on valve; VALVE light on

Transformer Box will glow and valve will open.

4.

Remove “short” between electrodes. VALVE light will

go out and valve will shut off.

E. Initial Setting and Operation

1.

Fill pail with water from rinse tank inlet water line.

2.

Move inside probe of the Controlstik (sensor) back to

highest scale reading and submerge into pail of water.

3.

Slowly push inside probe toward opposite end,

stopping when Solenoid Valve triggers and VALVE light

goes on. Water will begin to flow into the tank. Read

scale.

4.

For the initial setting, move the inside probe back to

read at least 25% higher than the scale reading in step

3. Tighten set screw with 9/64" Allen wrench (finger

tight is not sufficient).

5.

Place the Controlstik (sensor) back into the rinse tank

as described under Section A. Mounting, number 2.

Fasten the cord with the securing clamp provided.

6.

Check setting and overall operation by rinsing parts or

by pouring a small amount of acid or alkaline solution

into the rinse tank to trigger the Solenoid Valve and

start water flow.

7.

Adjust valve flow control handle to obtain desired flow

rate. Check through at least one complete on/off

cycle. This valve can also be operated manually. To

disengage the solenoid (convert valve to manual

operation) hold the cross handle firmly and loosen

(counterclockwise) the bolt in the center of the stem.

Some water will spurt out at the stem while it is under

manual control.

NOTE: The best Controlstik (sensor) setting can be

determined with experience. Since the main

objective of the system is to conserve water use, a

high conductivity setting on the sensor is desirable

… as long as the water does not become too dirty,

preventing effective rinsing. However, if the sensor

is set too low, the water will flow continuously due

to the normal conductivity (total dissolved solids) in

source water - defeating the purpose of the

system.

MAINTENANCE

A.

Controlstik (sensor)

Although this system is very stable, the sensor should be

regularly checked for hard water scale, which will lower its

sensitivity. Scale can be easily removed by agitating sensor

in a 2-10% hydrochloric acid solution. If scale has been

allowed to build up for a long period, a bristle brush may

also be used. The Controlstik (sensor) may be

disassembled by removing the set screw and thoroughly

cleaned if it should accidentally become completely fouled.

B.

Valve

Should the Controlstik Rinse Tank System no longer

activate the Solenoid Valve when the inside probe is

intentionally “shorted,” unscrew the solenoid from the side

of the valve and check the chamber for any solid matter

which may prevent easy solenoid movement.

3.

Bring Controlstik (sensor) electrodes together by sliding

the inside probe completely forward. Use a screwdriver