Myron L 767 User Manual

Page 7

Installation

NOTE:

The 750/760 Series Conductivity Monitors are not designed to

operate with a Cell cable length that exceeds 100' (30 meters).

STEP 3 If at all possible, mount the Monitor at eye level for

viewing convenience.

2.2.1 SURFACE MOUNTING WITH SMP ASSEMBLY

NOTE:

A Surface Mounting Plate (SMP) will be required when access to

the far side of the mounting site is impractical. For 750 series

monitors, use the SMP-50 and for 760 series monitors, use the

SMP-60. Surface mounting will require two (2)

1

/

4

" X 20

mounting screws. (The mounting screws are packaged with the

SMP assemblies.) If an SMP is being used, the user must

supply four (4) additional screws or bolts. Their size is to be

determined by the user.

STEP 1 Select your mounting location. Mark and drill the four

(4) required mounting holes. For hole locations, use the

SMP as a template. Install any lags or threads required.

STEP 2 Drill the corner holes in the SMP according to the size

of the screws or bolts selected.

STEP 3 Attach and securely fasten the SMP to the Monitor

using the

1

/

4

" X 20 X

3

/

8

" screws provided.

STEP 4 Mount the SMP to the prepared site using the selected

screws or bolts.

2.2.2 SURFACE MOUNTING WITHOUT SMP ASSEMBLY

NOTE:

Surface mounting will require two (2)

1

/

4

“ X 20 screws of a

length equal to the thickness of the mounting site plus

3

/

8

”

STEP 1 Select mounting site location. Mark and drill the

required mounting holes. For hole drilling locations, see

Fig. 2-1.

STEP 2 Insert the

1

/

4

" X 20 screws into the holes from the side

opposite the mounting site.

STEP 3 Hold the Monitor in place while starting and tightening

the mounting screws.

2.2.3 PANEL MOUNTING

A panel mounting fastening kit is provided with all Conductivity

Monitors. Panel mounting will require the use of the fastening

kit’s two (2) 4-40 mounting screws/nuts or two (2) #4 x 1/2"

sheet metal screws. See Fig. 2-1 for panel cutout dimensions.

STEP 1 Select your mounting location. Mark the appropriate

panel cutout and complete the necessary panel cut.

STEP 2 Carefully unfasten and separate the Monitor’s front

panel from its enclosure.

STEP 3 Disconnect all panel cable(s)/wires from the Monitor’s

Control board.

STEP 4 Slide the enclosure through the panel cutout until its

flange contacts the panel.

STEP 5 Insert mounting screws through the flange mounting

holes and tightly secure.

STEP 6 Reconnect all panel cable(s)/wires and re-secure the

front panel.

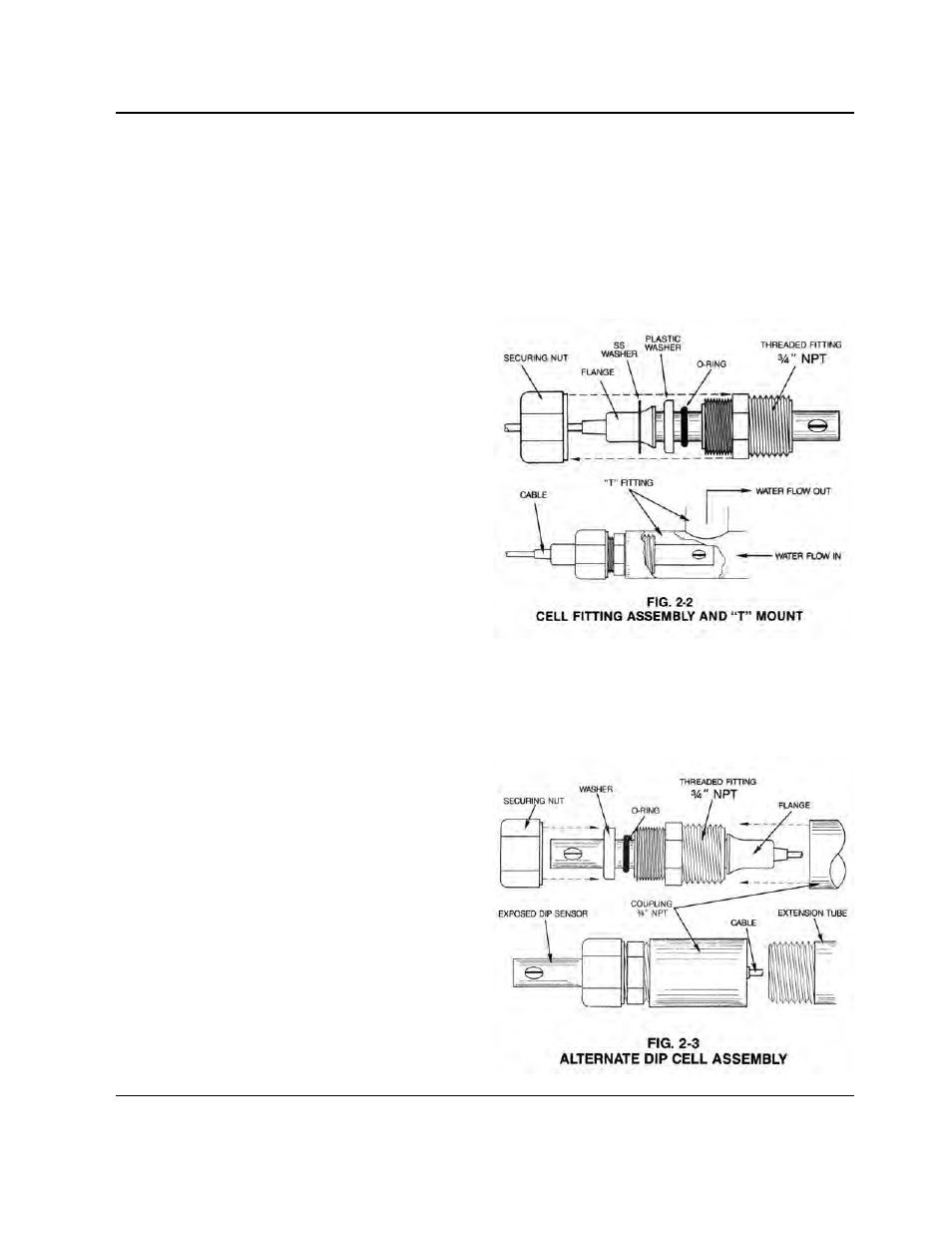

2.3 CELL INSERTION/DIP MOUNT ASSEMBLIES

A CS51 Cell’s mounting orientation must provide a continuous

and adequate circulation flow to prevent the trapping of air

bubbles within the Cell’s electrode area. Failure to do so will

result in conditions that will prevent the Cell from functioning

properly.

2.3.1 INSERTION MODE ASSEMBLY

STEP 1 Verify that the Cell’s Fitting assembly is properly

assembled as shown in Fig. 2-2.

STEP 2 Insert the Cell Fitting assembly into the “T” fitting as

shown in Fig 2-2 and tightly secure.

2.3.2 ALTERNATE DIP CELL ASSEMBLY

STEP 1 Verify that the Cell’s Fitting assembly is properly

assembled as shown in Fig. 2-3.

STEP 2 Insert and pull the Cell’s cable through the extension

tube and then tightly attach extension tube to Cell

assembly as shown in Fig. 2-3.

5