Ersa, Versaprint – kurtz ersa VERSAPRINT S1 EN User Manual

Page 2

2

Ersa

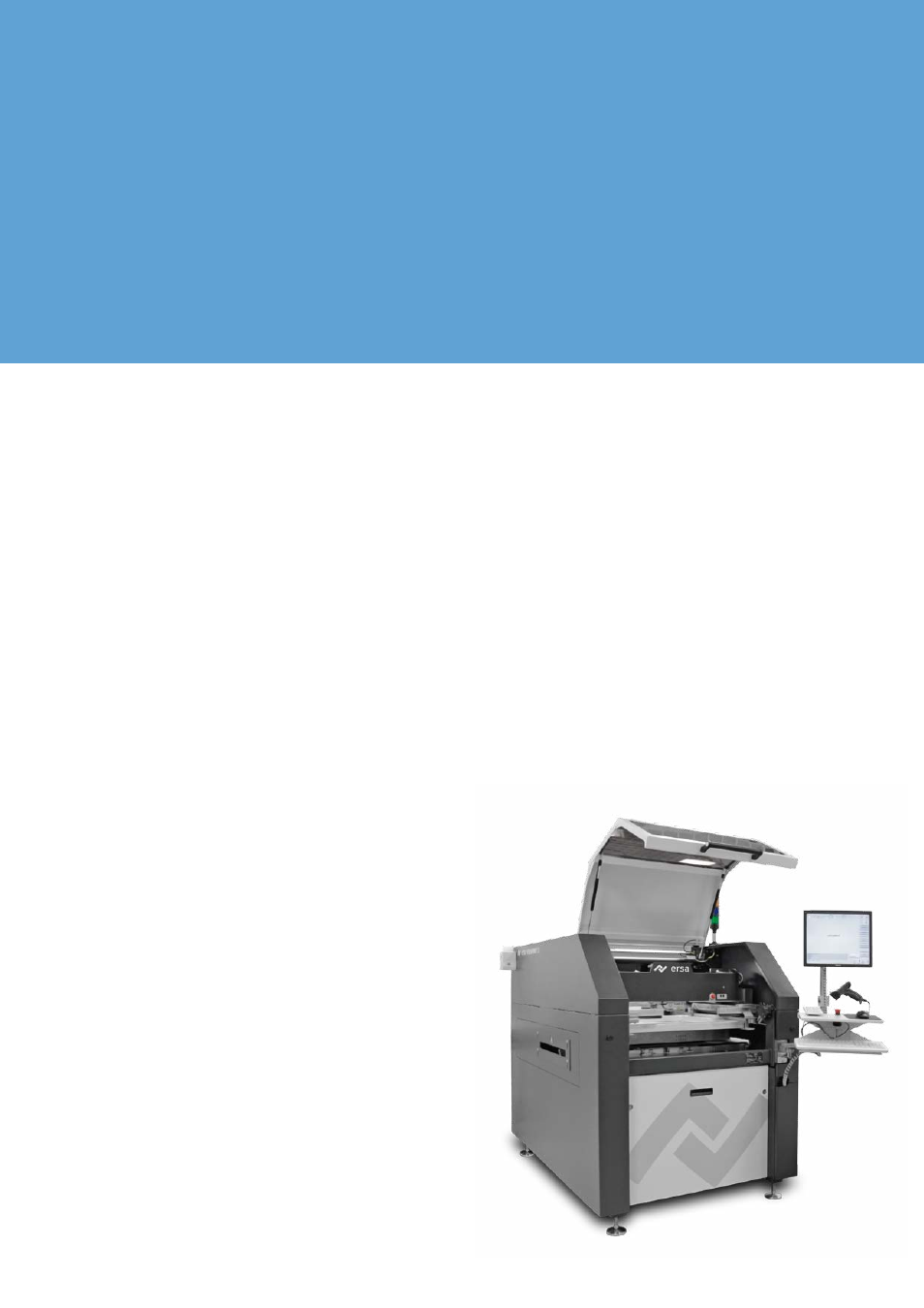

VERSAPRINT

A revolutionary printer with

fully integrated Post Print AOI

Market research shows that nearly

80 % of the defects produced in an

SMT production line result primar-

ily from the printing process with ap-

prox. 64 % and from the reflow pro-

cess with approx. 15 %. Ersa, Europe‘s

largest manufacturer of soldering

systems, has accepted this SMT chal-

lenge and has expanded its product

range by screen printers. This con-

sequential step clearly defines Ersa’s

role as a strategic system supplier

taking increased responsibility for the

entire SMT processes of printing and

reflow.

New technology

The revolutionary Line Scan Technol-

ogy (LIST) camera and the TRT (Triple

Rail Transport) define the focus of the

core competence of this new printer:

true time savings via optimized par-

allel processing and 100 % post print

AOI integrated into the machine.

LIST - Line Scan Technology

Today’s printers use a standard cam-

era for alignment and the same cam-

era to rapidly shoot many small field-

of-view pictures for inspection. Ersa

revolutionizes these processes via

the use of a line sensor based cam-

era for both alignment and inspec-

tion. Unlike commercial scanners, the

VERSAPRINT

S1

LIST camera has top and bottom con-

tact image sensors (CIS) and an array

of rod lenses specifically designed for

the VERSAPRINT application. Stan-

dard cameras take many pictures of

a very small area, whereby the LIST

camera scans an entire length of

260 mm at a speed of 35 mm per sec-

ond! From an inspection speed stand-

point, Ersa’s Line Scan Technology

will set the new standard. The fast-

est inspection speed in a printer to-

day is 1,200 mm²/s. The LIST cam-

era in the VERSAPRINT achieves the

world’s fastest inspection speed of

9,100 mm²/s! In addition to inspec-

tion speed, the scanning of the en-

tire substrate offers many additional

advantages.

Parallel processing:

TRT Triple Rail Transport

Optimizing production efficiency re-

mains the foremost goal of SMT

equipment manufacturers. In a print-

ing machine, the major process steps

are printing, transporting, cleaning

and inspecting. The printing, for ex-

ample, can be conducted simultane-

ously or parallel to an inspection pro-

cess and can achieve a relative cycle

time savings. The VERSAPRINT revo-

lutionizes parallel processing based

on a TRT Triple Rail Transport and the

100 % inspection capability offered by

LIST. The two most time consuming

processes of printing and inspection

can run parallel in order to achieve a

tremendous cycle time savings!

Print head: CPC Continuous

Pressure Control

Closed loop print pressure control of-

fers the best print results. Weight

compensation of print head and

squeegee realizes low print pres-

sure for highly sensitive applications.

Mounting the squeegee is very easy

and fast and is conducted from the

front side of printing head.