Allied Air Enterprises 4HP16LT User Manual

Page 18

DEFROST BOARD PRESSURE SWITCH

CONNECTIONS

The unit’s automatic reset pressure switches (LO PS -

S87 and HI PS - S4) are factory-wired into the defrost

board on the LO-PS and HI-PS terminals, respectively.

(OPTIONAL) Low Pressure Switch (LO-PS)

— When

the low pressure switch trips, the defrost board will cycle

off the compressor, and the strike counter in the board

will count one strike. The low pressure switch is ignored

under the following conditions:

!

during the defrost cycle and 90 seconds after the

termination of defrost

!

when the average ambient sensor temperature is below

15° F (-9°C)

!

for 90 seconds following the start up of the compressor

!

during “test” mode

High Pressure Switch (HI-PS)

— When the high

pressure switch trips, the defrost board will cycle off the

compressor, and the strike counter in the board will count

one strike.

DEFROST BOARD PRESSURE SWITCH SETTINGS

High Pressure

(auto reset) - trip at 590 psig; reset at

418.

Low Pressure

(auto reset) - trip at 25 psig; reset at 40.

5-STRIKE LOCKOUT FEATURE

The internal control logic of the board counts the pressure

switch trips only while the Y1 (Input) line is active. If a

pressure switch opens and closes four times during a Y1

(Input), the control logic will reset the pressure switch trip

counter to zero at the end of the Y1 (Input). If the

pressure switch opens for a fifth time during the current

Y1 (Input), the control will enter a lockout condition.

The 5-strike pressure switch lockout condition can be

reset by cycling OFF the 24-volt power to the control

board or by shorting the TEST pins between 1 and 2

seconds. All timer functions (run times) will also be reset.

If a pressure switch opens while the Y1 Out line is

engaged, a 5-minute short cycle will occur after the switch

closes.

DEFROST SYSTEM SENSORS

Sensors connect to the defrost board through a field–

replaceable harness assembly that plugs into the board.

Through the sensors, the board detects outdoor ambient,

coil, and discharge temperature fault conditions. As the

detected temperature changes, the resistance across the

sensor changes. Sensor resistance values can be

checked by ohming across pins .

NOTE - When checking the ohms across a sensor, be

aware that a sensor showing a resistance value that

is not within the range shown, may be performing as

designed. However, if a shorted or open circuit is

detected, then the sensor may be faulty and the

sensor harness will needs to be replaced.

Coil Sensor

—The coil temperature sensor considers

outdoor temperatures below -35°F (-37°C) or above

120°F (48°C) as a fault. If the coil temperature sensor is

detected as being open, shorted or out of the temperature

range of the sensor, the board will not perform demand or

time/temperature defrost operation and will display the

appropriate fault code. Heating and cooling operation will

be allowed in this fault condition.

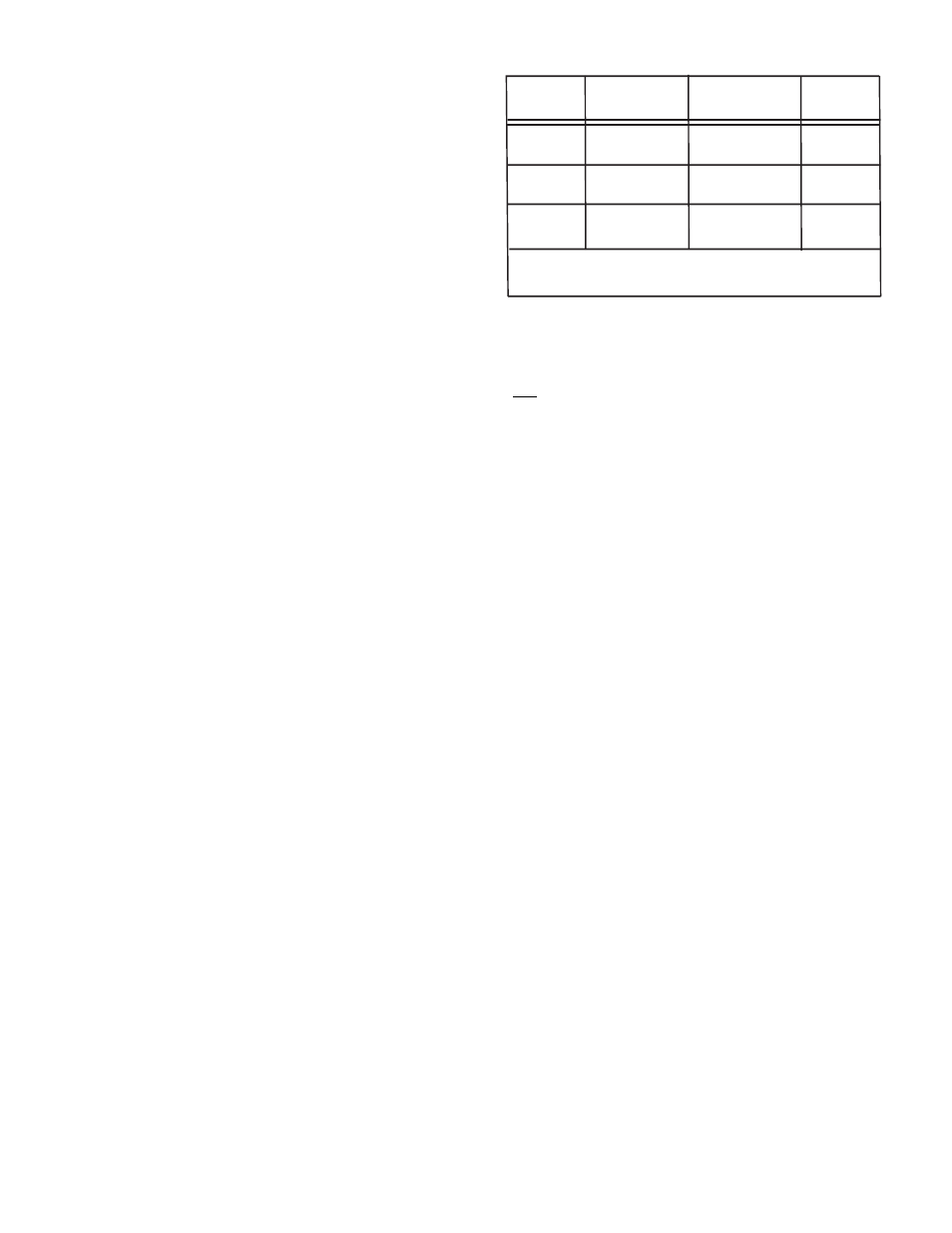

Sensor

Temperature

Range °F (°C)

Red Led (DS1)

Outdoor

(Ambient)

Coil

Discharge (If

applicable)

Note: Sensor resistance decreases as sensed temperature increases.

Pins/Wire

Color

-35 (-37 to 120

(48)

280,000 to 3750

3 & 4

(Black)

-35 (-37) to 120

(48)

280,000 to 3750

24 (-4) to 350

(176)

41,000 to 103

5 & 6

(Brown)

1 & 2

(Yellow)

Sensor Temp. / Resistance Range

Ambient Sensor

—The ambient sensor considers

outdoor temperatures below -35°F (-37°C) or above

120°F (48°C) as a fault. If the ambient sensor is detected

as being open, shorted or out of the temperature range of

the sensor, the board will not perform demand defrost

operation. The board will revert to time/temperature

defrost operation and will display the appropriate fault

code. Heating and cooling operation will be allowed in this

fault condition.

NOTE - Within a single room thermostat

demand, if 5-strikes occur, the board will lockout

the unit. Defrost board 24 volt power “R” must

be cycled “OFF” or the “TEST” pins on board

must be shorted between 1 to 2 seconds to reset

the board.

506468-01

Page 18

Issue 1004