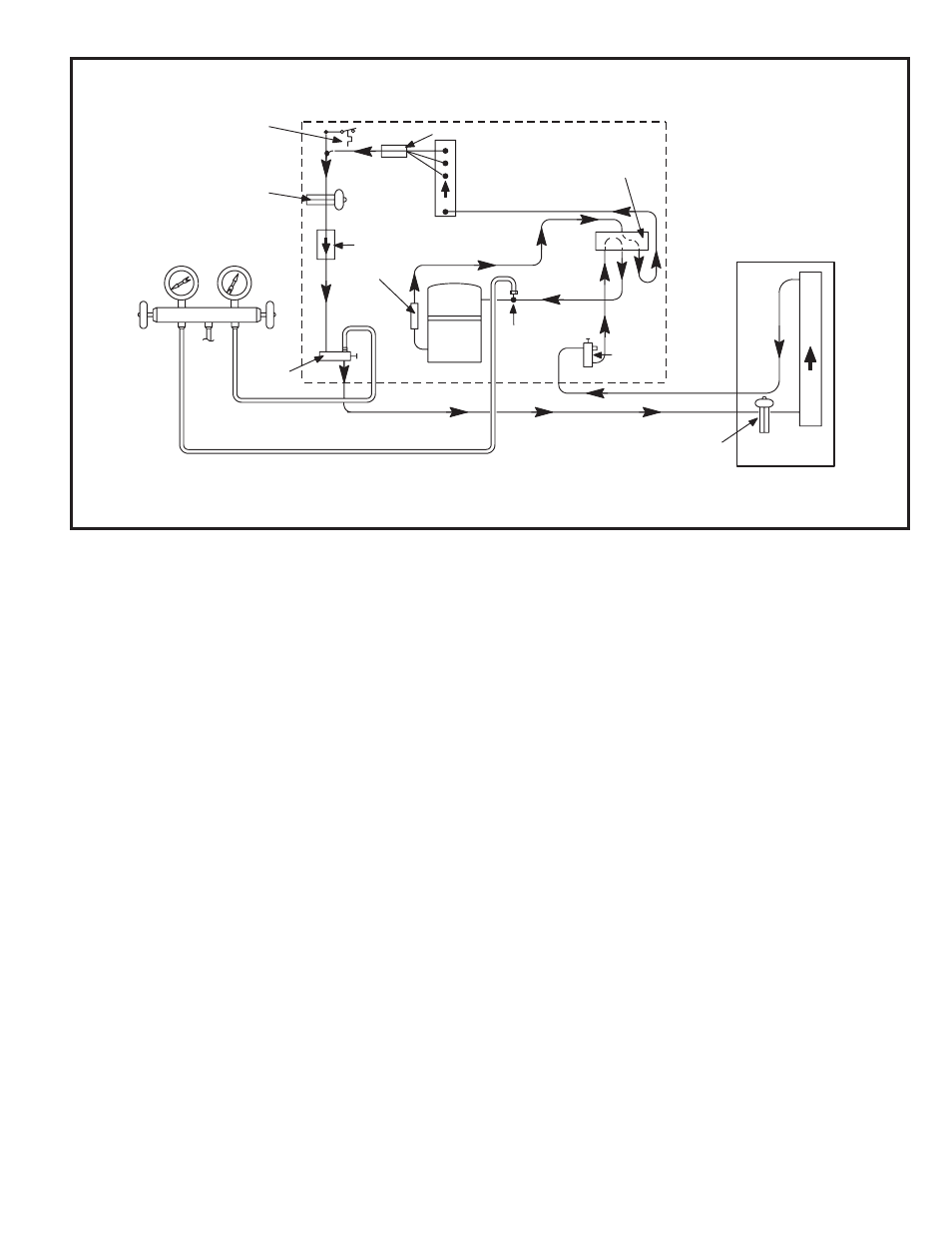

Cooling cycle, Figure 12 – Allied Air Enterprises 4HP16LT User Manual

Page 13

506468-01 Issue 1004 Page 13

Cooling Cycle

Use gauge ports on suction line valve and liquid line valve for evacuating refrigerant lines and indoor coil. Use

suction gauge port to measure suction pressure during charging.

Figure 12

OUTDOOR COIL

DEFROST THERMOSTAT

EXPANSION/CHECK VALVE

BIFLOW

FILTER / DRIER

TO

R410A

DRUM

LOW

PRESSURE

HIGH

PRESSURE

COMPRESSOR

REVERSING VALVE

SUCTION

LINE

VALVE

MUFFLER

NOTE - ARROWS INDICATE

DIRECTION OF

REFRIGERANT FLOW

SUCTION

SERVICE

PORT

EXPANSION/CHECK VALVE

INDOOR UNIT

OUTDOOR UNIT

LIQUID

LINE

SERVICE

PORT

GAUGE MANIFOLD

DISTRIBUTOR

INDOOR

COIL

•

Low pressure gauge to suction line service valve

•

High pressure gauge to liquid line service valve

2. Close manifold gauge set valves. Connect the center

manifold hose to an upright cylinder of R410A.

3. If room temperature is below 70°F, set the room thermo-

stat to call for heat. This will create the necessary load

for properly charging the system in the cooling cycle.

4. Use a digital thermometer to record the outdoor

ambient temperature.

5. When the heating demand has been satisfied, switch

the thermostat to cooling mode with a set point of 68°F.

When pressures have stabilized, use a digital thermom-

eter to record the liquid and suction line temperatures.

6. The outdoor temperature will determine which charg-

ing method to use. Proceed with the appropriate

charging method.

Charge Using Weigh-In Method

If the system is void of refrigerant, or if the outdoor ambient

temperature is cool, first locate and repair any leaks then

use the weigh-in method to charge the unit.

1. Recover the refrigerant from the unit.

2. Conduct a leak check, then evacuate as previously

outlined.

3. Weigh in the charge according to the total amount

shown on the unit nameplate.

If weighing facilities are not available, use one of the

following procedures to charge the unit.

Charge Using Subcooling Method –

Outdoor Temperatures Below 65°F

When the outdoor ambient temperature is below 65°F, the

subcooling method can be used to charge the unit. It may

be necessary to restrict the air flow through the outdoor

coil to achieve pressures in the 200-250 psig range.

These higher pressures are necessary for checking the

charge. Block equal sections of air intake panels and

move obstructions sideways until the liquid pressure is in

the 200-250 psig range (see Figure 13 on page 14).

1. With the manifold gauge hose still on the liquid

service port and the unit operating stably, use a digital

thermometer to check the liquid line temperature. For

best results, use the same digital thermometer to

check both the outdoor ambient and the liquid line

temperatures.

2. At the same time, record the liquid line pressure reading.

3. Use the temperature/pressure chart (Table 5 on page 14)

to determine the saturation temperature for the liquid line

pressure reading.