American Aldes Hood Liner User Manual

Read and save these instructions, Part 1 planning the installation

NOTES:

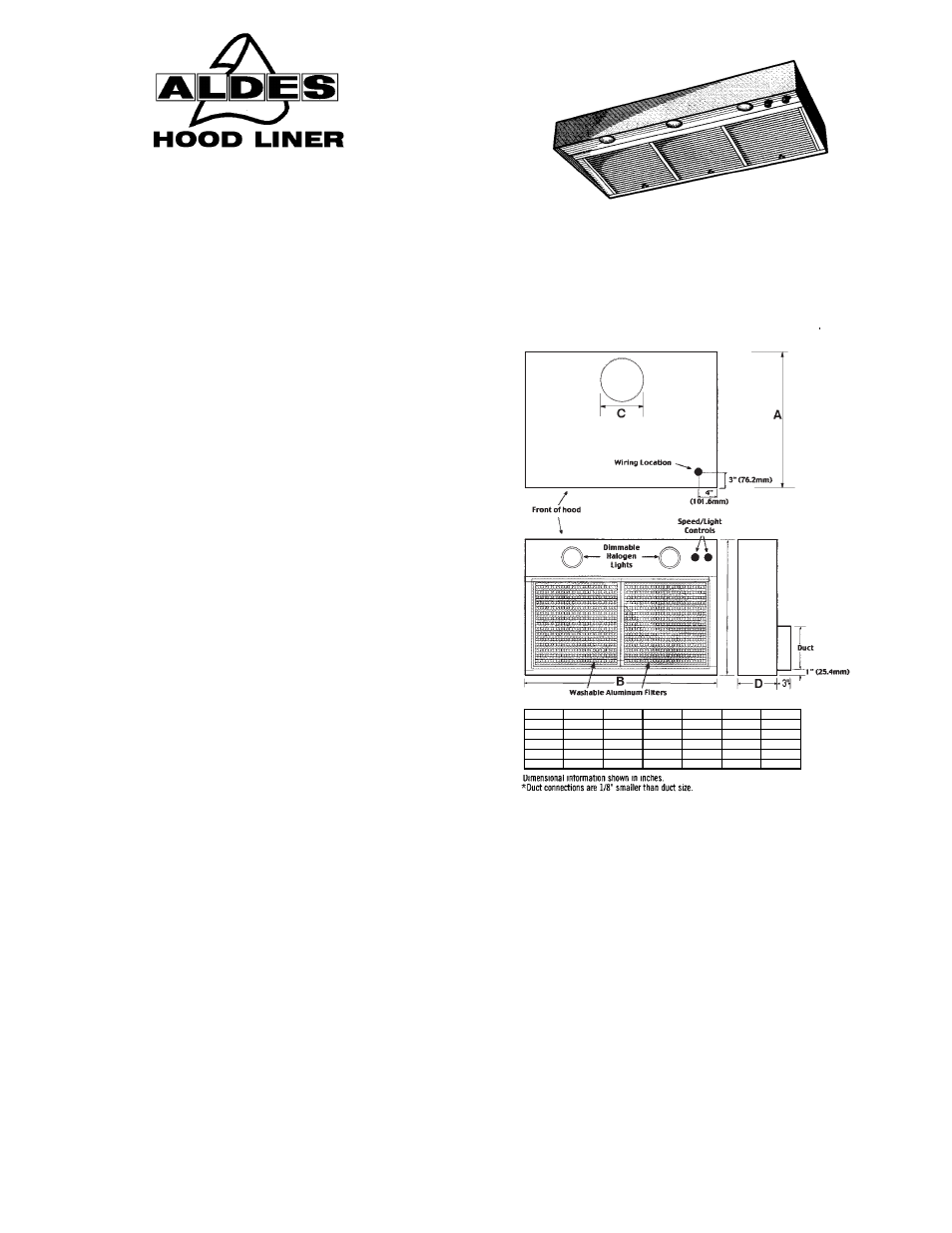

• The hood liner is designed to install inside a custom hood enclosure and operates with a

remotely mounted blower (purchased separately). See Fig. below for hood dimensions.

See chart for ALDES exhaust fans recommended for use with this unit.

• A qualified person must complete the installation of this appliance.

• Plan the installation so that all minimum clearances are met or exceeded.

• IMPORTANT: You must provide support framing and backing in the areas in which you

are securing the liner to in your custom canopy. Failure to do so could damage the liner

and void the warranty.

All dimensional tolerances are 0” to 1/16” unless otherwise stated.

NOTES:

1. The hood liner uses 120 VAC, 60 Hz power. Supply wires should be installed by a

qualified person(s) and must meet all electrical codes. The HLS-30 & HLS-36 Hood

Liner are designed for use with 6” duct. The HLD-36 is designed for use with 8” diameter

round duct and the HLD-42 and HLD-48 Hood Liner are designed for use with 10” diam-

eter duct. Use only rigid metal duct.

2. “Duct Silencers” are available from American ALDES. When planning for installation

using a Duct Silencer, please refer to the installation instructions provided with the unit.

3. A quality cap with built in backdraft damper or an in-line damper is recommended to

minimize cold air return through the duct when the product is not in use.

4. Always install ventilation products with an approved wall or roof cap.

5. Duct performance is improved by using round, smooth metal duct work instead of rectan-

gular.

6. If multiple elbows must be used, ensure that there is a minimum of 24” of straight duct

between any two elbows.

7. Avoid “S” or back to back configurations caused by adjacent elbows.

8. Route ducting to terminate at the hood liner.

WARNINGS:

Following Are Manufacturer’s Suggestions. Always Observe Local Building Codes.

1. Liners installed in custom canopies constructed of combustible materials, should be installed with the

combustible material structure a minimum of 36” above the surface of the heating element.

2. Liners installed in custom canopies constructed of noncombustible materials, should be installed with

the noncombustible material structure a minimum of 30” above the surface of the heating element.

3. Follow all instructions regarding minimum safe clearances and installation location. Failure to do so

may result in a safety hazard or fire.

4. To reduce the risk of fire, use only metal ductwork.

READ AND SAVE THESE INSTRUCTIONS

• Before beginning installation, please thoroughly read and become familiar with these instruc-

tions.

• Installation and service must be completed by a qualified installer.

• Failure to properly install this product may void the warranty.

Installer:

Please leave these installation instructions with the homeowner.

Owner:

Please keep these installation instructions for local electrical inspector’s use for fu-

ture reference.

WARNINGS: TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PER-

SONS OBSERVE THE FOLLOWING:

A) Use this unit only in the manner intended by the manufacturer. If you have any ques-

tions, contact the manufacturer.

B) Before servicing or cleaning unit, switch power off at service panel and lock the service

disconnecting means to prevent power form being switched on accidentally. When the

service disconnecting means cannot be locked, securely fasten a prominent warning

device, such as a tag to the service panel.

C) Installation work and electrical wiring must be done by qualified person(s) in accordance

with all applicable codes and standards, including fire-rated construction.

D) Sufficient air is needed for proper combustion and exhausting of gasses through the flue

(chimney) or fuel burning equipment to prevent backdrafting. Follow the heating equip-

ment manufacturer’s guideline and safety standards such as those published by the

National Fire Protection Association (NFPA) and the American Society for Heating, Re-

frigeration and Air Conditioning Engineers (ASHRAE) and the local code authorities.

E) When cutting or drilling into wall or ceiling, do not damage electrical wiring and other

hidden utilities.

F) Duct fans must always be vented to the outdoors.

CAUTION: For general ventilating use only. Do not use to exhaust hazardous or explosive mate-

rials and vapors.

WARNINGS: TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

A) Never leave surface units unattended at high settings. Boil-overs may cause smoking

and greasy spillovers that may ignite. Heat oils slowly on low or medium settings.

B) Always turn hood ON when cooking at high heat or when cooking flaming foods.

C) Clean ventilating fans frequently. Grease should not be allowed to accumulate on fan or

filter.

D) Use proper pan size. Always use cookware appropriate for the size of the surface ele-

ment.

WARNING: TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT OF A RANGE

TOP GREASE FIRE, OBSERVE THE FOLLOWING:

A) SMOTHER FLAMES with a close-fitting lid, cookie sheet or metal tray, then turn off the

burner. BE CAREFUL TO PREVENT BURNS. If the flames do not go out immediately,

EVACUATE AND CALL THE FIRE DEPARTMENT.

B) NEVER PICK UP A FLAMING PAN! You may be burned.

C) DO NOT USE WATER, including wet dishcloths or towels - a violent steam explosion will

result.

D) Use an extinguisher ONLY if:

1. You know you have a Class ABC extinguisher, and you already know how to

operate it.

2. The fire is small and contained in the area where it started.

3. The fire department is being called.

4. You can fight the fire with your back to an exit.

PART 1 Planning the Installation

CAUTION:

1. To reduce the risk of fire and to properly exhaust air, the liner must be exhausted to the

outside. Never exhaust into a wall, an attic or a concealed area in the building. This can

create a potential hazard.

2. Consult a licensed ventilation contractor or qualified technician for proper installation of

exhaust ducting.

3. Locate the cooking area for minimum cross drafts -- away from doors and windows,

when possible.

4. Ducts must be of adequate size and duct runs should be as short as possible. When

turns are necessary, keep turning radius as large and as smooth as possible.

5. The ducting must be air tight. Use a minimum of 2 sheet metal screws at every duct joint.

Then, seal the duct joints with high quality duct tape.

6. Only use ductwork constructed of materials deemed acceptable by state, municipal and

local codes.

MODEL

UPC#

DUCT*

A

B

C

D

HLS-30

71 130

6

18

28-1/2

6

4

HLS-36

71 131

6

18

34-1/2

6

4

HLD-36

71 136

8

22

34-1/2

8

6

HLD-42

71 142

10

22

40-1/2

10

6

HLD-48

71 148

10

22

46-1/2

10

6