Shutting down, Transport storing the device maintenance and care, Warranty troubleshooting – Karcher HWE 860 User Manual

Page 7

-

2

Turn the main switch to position “0”.

Shut off water supply.

Unscrew the water inlet hose and high

pressure hose from the appliance.

Unscrew closing stopper on the bottom

of the boiler and empty the boiler.

Let the high-pressure pump run for

max. of 1 minute, until the pump and

pipes are empty.

The machine should be stored in frost-free

rooms. In case there is frosting risk, for e.g.

if the machine is installed in open areas,

then the machine must first be emptied and

flushed using an anti-freezing agent.

ṇ

Warning

Frost will destroy the not completely water

drained device.

Drain water.

Flush device with anti-freeze agent.

A certain corrosion protection is

achieved with this as well.

Caution

Risk of injury and damage! Observe the

weight of the appliance when you transport it.

When transporting in vehicles, secure the

appliance according to the guidelines from

slipping and tipping over.

Caution

Risk of injury and damage! Note the weight

of the appliance in case of storage.

This appliance must only be stored in inte-

rior rooms.

ƽ

Danger

Risk of injury! The main switch is to be

switched off while carrying out any repairs

or maintenance jobs.

Check the connection cables.

The connection cable must not be dam-

aged (risk of electrical shock). A dam-

aged connection cable must be

replaced immediately by an authorised

Customer Service Engineer or an elec-

trician.

Check hot water hose.

The hot water hose must not be dam-

aged. A damaged hose must be re-

placed immediately (danger of burns).

Calcified appliances worsen the heat trans-

fer and the efficiency is reduced.

ƽ

Danger

Risk of explosion due to combustible gas-

es! Smoking strictly prohibited during de-

calcification. Ensure proper ventilation.

ƽ

Danger

Risk of burns injury on account of acid!

Wear protective glasses and protective

gloves.

According to statutory requirements, only

tested and approv approved boiler decrust-

ing agents may be used.

–

RM 100 (Order No. 6.287-008) dis-

solves chalk and simple compounds of

chalk and detergents residues.

Fill the boiler with 30 liters of water.

Connect the water hose directly to the

water input and hang in the other free

end into the container.

Unscrew the nozzle of the steel pipe.

Also insert the connected spray pipe of

the high-pressure cleaner into the con-

tainer. This is how a cycle is created:

Container - pump - boiler.

Pour 2 l of decalcifying solution into the

container.

Let high-pressure pump run.

The solution must not become hotter

than 60 °C. Ensure that there are no

steam bubbles (do not mistake them for

foam).

If there is no visible gas generation after

15 minutes, pour another 0.5 l of decal-

cifying solution into the container (max.

concentration 7%). With regular decal-

cifying, this will only take approx. 3 min-

utes.

The warranty terms published by the rele-

vant sales company are applicable in each

country. We will repair potential failures of

your appliance within the warranty period

free of charge, provided that such failure is

caused by faulty material or defects in man-

ufacturing. In the event of a warranty claim

please contact your dealer or the nearest

authorized Customer Service centre.

Please submit the proof of purchase.

ƽ

Danger

Risk of injury! The main switch is to be

switched off while carrying out any repairs

or maintenance jobs.

ƽ

Danger

Risk of electric shock! The inspection of

electrical components may only be per-

formed by the authorised customer service.

Shutting down

Emptying the appliance

Frost protection

Transport

Storing the device

Maintenance and care

Visual check

Decalcify boiler.

Warranty

Troubleshooting

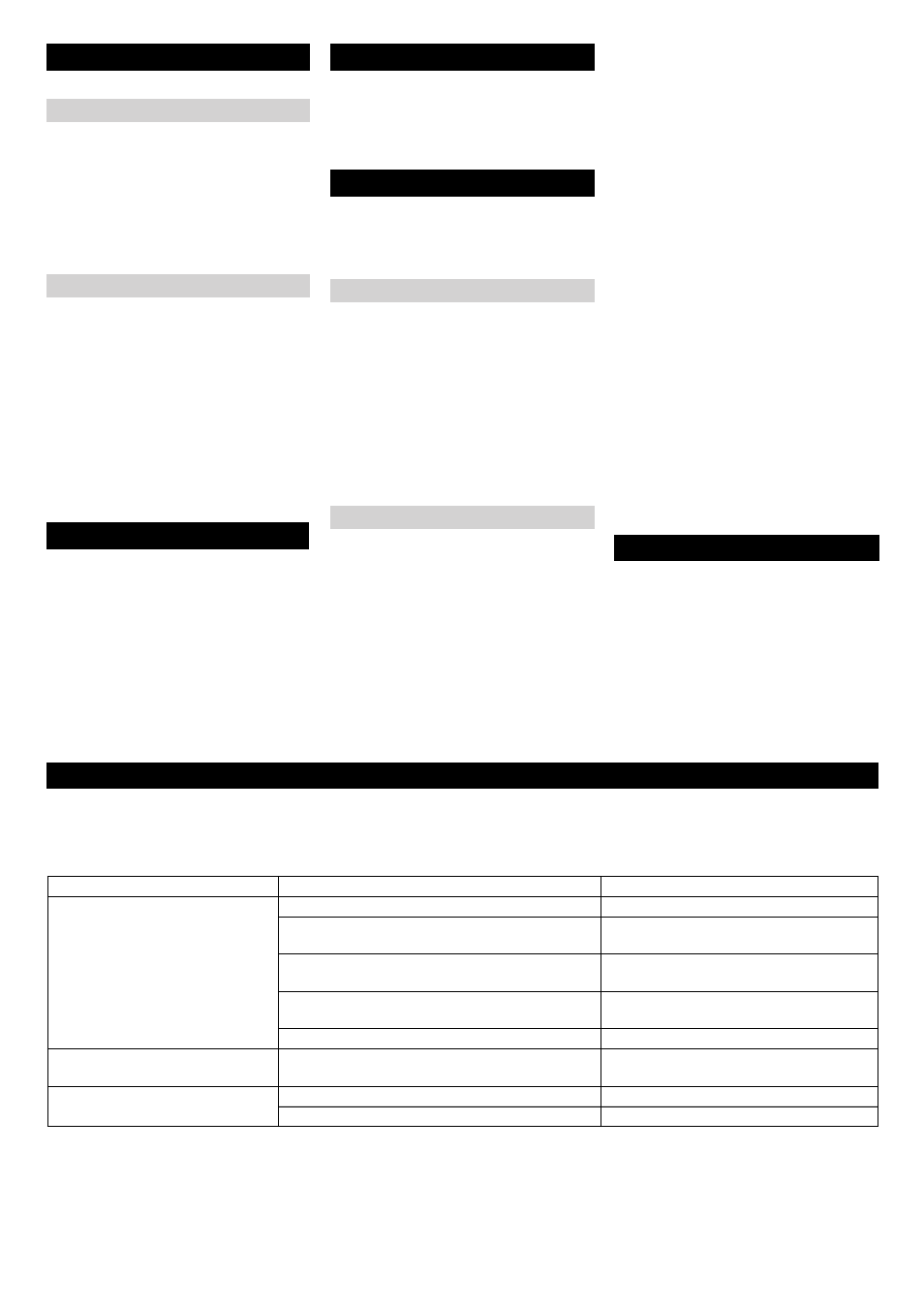

Fault

Possible cause

Remedy

Appliance does not heat up

There is no voltage in the machine.

Check building fuse.

Fuse in the control circuit has burnt out. Fuse is lo-

cated in the control transformer.

Insert new fuses. If it burns out again, check

reason for overload.

Protective motor switch in the switch cabinet was

triggered

Unlock motor protection switch. Contact

Customer Service if the fault recurs.

Temperature regulator defective, temperature limit-

er has switched off the appliance.

Inform Customer Service

Contactor is not working.

Inform Customer Service

Indicator lamp for liquid softener

blinks red

No liquid softener in the container.

Refill liquid softener.

Appliance does not heat up properly Heating coil has heavy calcium deposits.

Decalcify the heating coil.

Thermostat is defective.

Inform Customer Service

7

EN