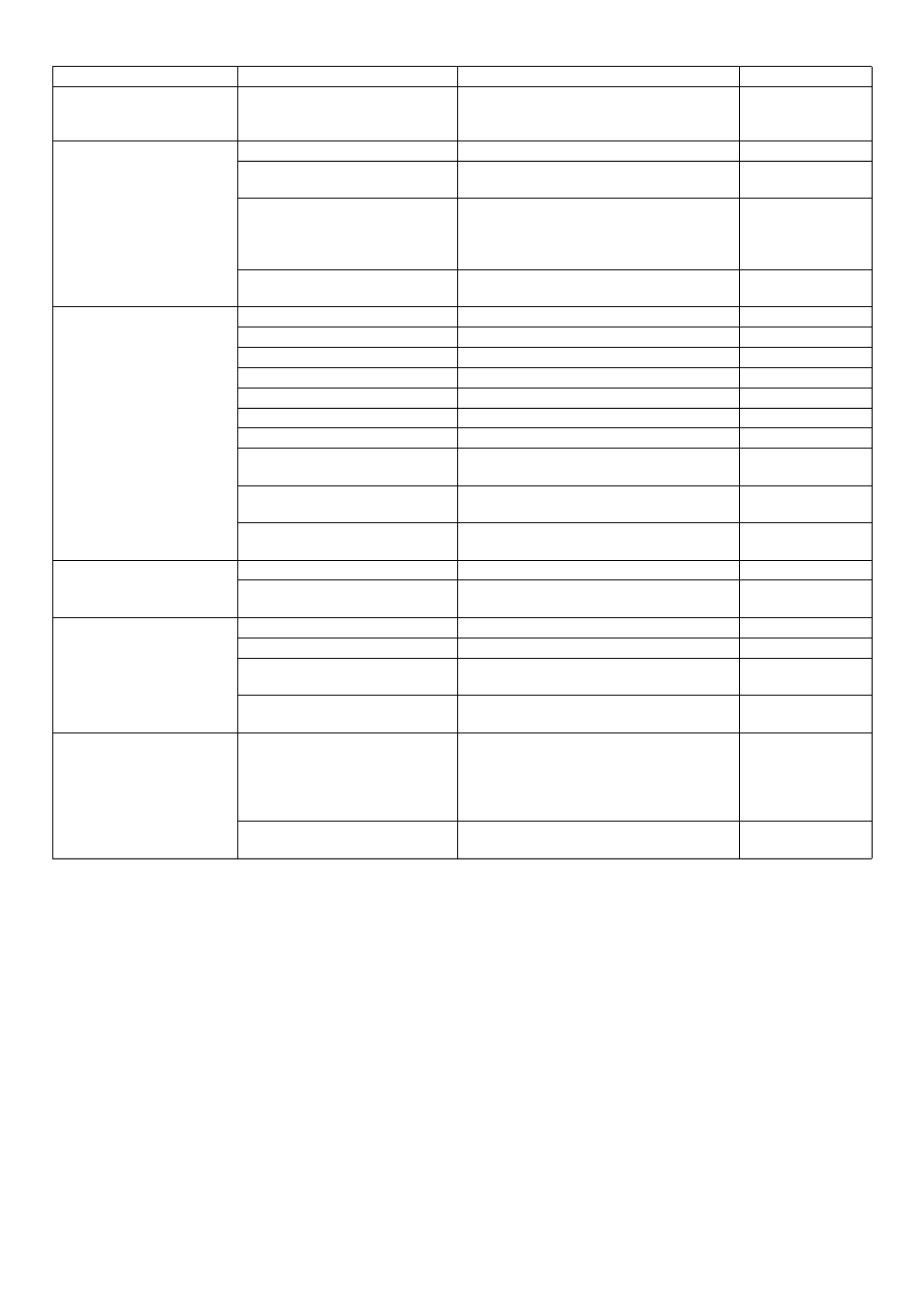

Fault, Possible cause, Remedy – Karcher HDS 9-14-4 ST User Manual

Page 33: Of whom, The softener is over, Refill the softener, Operator, Inadequate or no flow of detergent, Dosing valve to position "0, Adjusting the detergent metering valve

-

12

Fault

Possible cause

Remedy

of whom

Indicator lamp for protection

against calcification (H)

glows

The softener is over.

Refill the softener.

Operator

Inadequate or no flow of de-

tergent

Dosing valve to position "0".

Adjusting the detergent metering valve.

Operator

Detergent filter blocked or tank is

empty.

Clean and/or refill.

Operator

Detergent suction hoses, deter-

gent metering valve or detergent

solenoid valve are leaky or

blocked.

Check, clean.

Operator

Electronics or solenoid valve is de-

fective.

Replace

Customer Service

Full pressure does not build

up in the appliance

Flushed the nozzle.

Replace the nozzle.

Operator

Detergent tank is empty.

Refill detergent.

Operator

Not enough water

Ensure adequate water supply.

Operator

Sieve at the water inlet is blocked. Check, dismantle sieve and clean it.

Operator

Leaky detergent dosing valve.

Check and seal it.

Operator

Leaky detergent hoses.

Replace

Operator

Swimmer valve is jammed.

Check and ensure that it moves freely.

Operator

Safety valve is leaky.

Check the setting; install new washers, if re-

quired.

Customer Service

Flow valve is leaky or has been set

at a low value.

Check valve parts; replace damaged parts;

clean the dirt.

Customer Service

Solenoid valve for pressure re-

lease is defective.

Replace solenoid valve.

Customer Service

High pressure pump is

knocking; manometer is

swaying wildly

Vibration dampener is defective.

Replace vibration dampener.

Customer Service

Water pump does not suck in ade-

quate air.

Check suction system and remove leaks.

Operator

Device continuously turns on

and off while hand spray gun

is open

Nozzle in spray pipe is blocked.

Check, clean.

Operator

Appliance is decalcified.

See section "Descaling".

Operator

Switching point of the over-current

monitor has got shifted.

Get somebody to reset the over-current mon-

itor.

Customer Service

Sieve blocked in the water short-

age safe guard.

Check, dismantle sieve and clean it.

Operator

Appliance does not switch off

when the hand-spray gun is

closed

The pump has not been fully vent-

ed.

Set the machine switch to "0" and pull the

hand-spray gun until no fluid comes out of the

nozzle. Turn on the appliance again. Repeat

this procedure until the full operating pres-

sure is reached.

Operator

Safety valve or safety valve wash-

er is defective.

Replace the safety valve and/or the washer. Customer Service

33

EN