Maintenance and care, M danger, Maintenance schedule – Karcher HDS 9-14-4 ST User Manual

Page 30: Time, Activity, Assembly affected, Performance, Of whom, Daily, Check hand- spray gun

-

9

ƽ

Danger

Risk of injury! The main switch of the vacuum cleaner is to be

switched off or the Cekon plug must be unplugged while carrying

out any repairs or maintenance jobs.

Maintenance and care

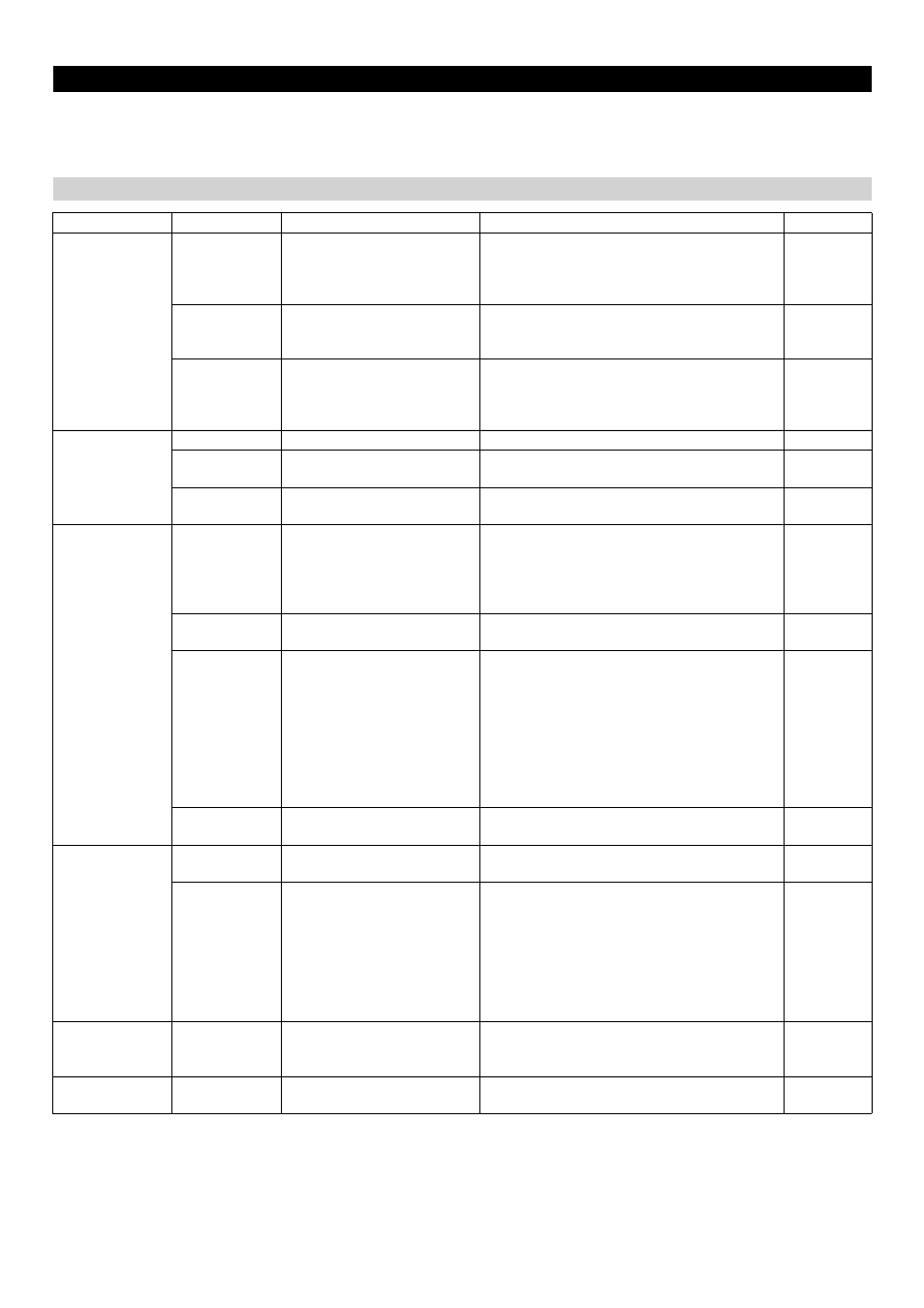

Maintenance schedule

Time

Activity

Assembly affected

Performance

of whom

daily

Check hand-

spray gun

Hand spray gun

Check whether the hand-spray gun closes tightly

without any leaks. Check the protection mecha-

nism against accidental switching. Replace de-

fective hand-spray guns.

Operator

Check high pres-

sure hoses

Outlets, hoses towards working

machine

Check hoses to see if there are damages. Re-

place defect hoses immediately. Danger of acci-

dent!

Operator

Check the con-

necting line with

mains plug

Electrical connection with plug/

socket

Check the connecting line with mains plug for

damages. If the power cord is damaged, please

arrange immediately for the exchange by an au-

thorized customer service or a skilled electrician.

Operator

weekly or after 40

operating hours

Check oil level

Oil tank at the pump

If the oil is milky, it needs to be replaced.

Operator

Check oil level

Oil tank at the pump

Check oil level of the pump. Refill oil if required

(Order no. 6.288-016)

Operator

Cleaning the

sieve

Sieve in water inlet

See section "Clean sieve".

Operator

monthly or after

200 operating

hours

Clean and check

the ignition elec-

trodes

Ignition electrodes located in

the lid of the continuous heater

Unscrew the fuel pipe, dismantle the electrode

holder and clean the electrodes. Check the elec-

trode setting according to the diagram on the fol-

lowing page and make the necessary

adjustments.

Trained op-

erator

Check pump

High-pressure pump

Check the pump for leaks. If the leakage is more

than 3 drops per minute, call Customer Service.

Operator

Check for inter-

nal deposits

Entire plant

Operate the machine using the spray pipe with-

out the high pressure nozzle. If the operating

pressure on the manometer of the machine in-

creases to more than 3 MPa, then the plant

needs to be decalcified. The same is applicable

when an operating pressure of more than 0.7 - 1

MPa is detected while operating the machine

without high pressure pipe (water comes out

freely at the high pressure outlet).

Operator

trained in de-

calcification

Cleaning the

sieve

Sieve in the water shortage

safeguard

See section "Clean sieve".

Operator

half-yearly or after

1000 operating

hours

Oil change

High-pressure pump

Drain off oil. Fill in 1 l new oil (Order no. 6.288-

016). Check oil level in the oil tank.

Operator

check, clean

Entire plant

Visual inspection of the plant, check high pres-

sure connections to see that they are not leaking,

check that the over-flow valves are not leaking,

check high pressure hoses, pressure tanks,

clean/ replace fuel filters, remove the rust/ calci-

um deposits from the heating coil, clean/ replace

ignition electrodes, clean/ replace burner nozzle,

adjust burner.

Customer

Service

annual

Safety check

Entire plant

Perform a safety inspection as per the applicable

national rules and regulations for liquid spray jets

of the respective country.

Technical

expert

at least every 5

years, recurring

Pressure test

Entire plant

Perform the pressure test as per manufacturer's

instructions.

Technical

expert

30

EN