Alto-Shaam ASF-75G User Manual

Page 13

Gas Fryer Operation & Care Manual • 12

O P E R A T I O N

OIL/SHORTENING REQUIREMENTS

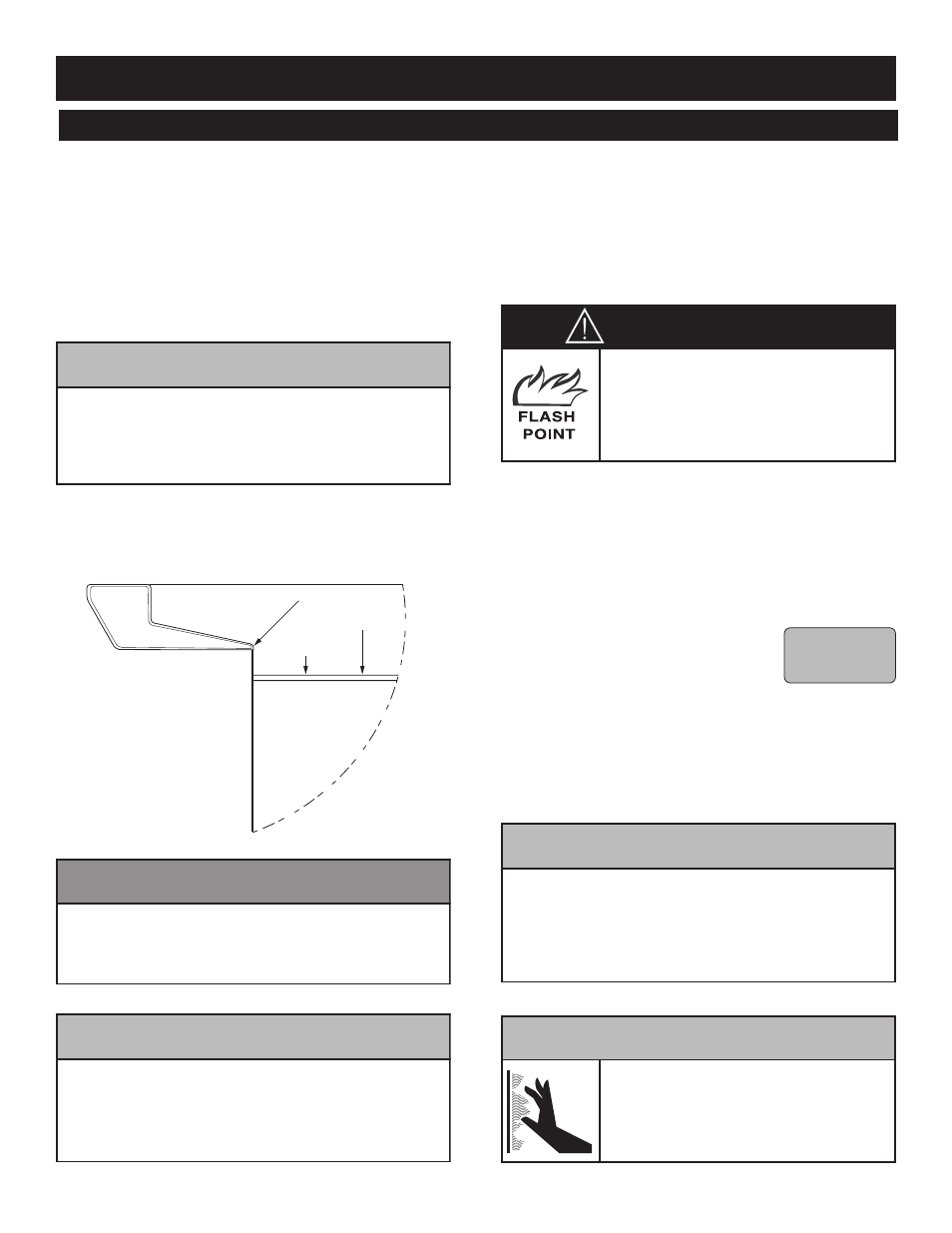

The ASF-75G requires 73-pounds (33 kg) of oil or

shortening in the frypot and the ASF-60G requires

62-pounds (28 kg) of oil or shortening. Use only

quality, high-grade oil/shortening in the fryer. The high

moisture content of many lower grade shortening will

result in excessive foaming and boil over. The cold

oil/shortening level requirement for the fryer is indicated

below.

NOTE: Always maintain the proper level of

shortening by adding fresh oil/shortening

to the frypot whenever needed.

Check the quality of the oil/shortening in the frypot on a

daily basis for signs of deterioration. Use an approved test

kit. Signs of shortening deterioration include excessive

boiling, smoking, foaming, bad taste, and rancid odor.

Discard any shortening before it degrades to the point of

affecting product quality. Always filter the oil on a regular

basis and keep the frypot clean.

Remove ice crystals and ensure that food is dry before

frying. Excessive water and ice can cause oil to splatter or

overflow. Do not over fill the basket. Food needs to be

surrounded by oil for best frying results.

Maximum shortening life is achieved by lowering the

temperature of the fryer to 250°F (121°C) whenever the

fryer is not being used. This is an

automatic program function through the

control program designation of

“IdleMode

.” The factory default is set at

a period of 30 minutes of non use before triggering a

temperature decrease, however; this time period can be

adjusted between “0” and “60” minutes. (

SEE

PROGRAMMING THE CONTROL

)

MAXIMUM HOT OIL FILL LINE

MINIMUM

HOT OIL FILL LINE

TOP BEND INSIDE

OIL KETTLE

F

R

O

N

T

O

F

K

E

T

T

L

E

3 0 : 0 0

IdleMode

O I L

/

S H O RT E N I N G

L E V E L S

O I L / S H O R T E N I N G R E Q U I R E M E N T S

C A U T I O N

METAL PARTS OF THIS EQUIPMENT

BECOME EXTREMELY HOT WHEN IN

OPERATION. TO AVOID BURNS,

ALWAYS USE HAND PROTECTION

WHEN OPERATING THIS APPLIANCE.

C A U T I O N

KEEP A CONTAINER OF COLD WATER ON HAND

DURING BOIL-OUT IN CASE OF BOIL-OVER. IF BOIL-

OVER IS IMMINENT, IMMEDIATELY TURN OFF MASTER

POWER SWITCH AND POUR COLD WATER INTO FRYPOT

TO QUICKLY REDUCE SOLUTION TEMPERATURE.

W A R N I N G

FAILURE TO PLACE SOLID SHORTENING

DIRECTLY ON THE BOTTOM OF THE

FRYPOT CAN CAUSE SERIOUS

E QU I P M E N T DA M AG E .

C A U T I O N

ENSURE THERE IS NO WATER IN THE FRYPOT BEFORE

FILLING WITH OIL/SHORTENING. WHEN COOKING

COMPOUNDS ARE HEATED TO COOKING

TEMPERATURE, WATER IN THE FRYPOT WILL CAUSE

OIL TO SPLATTER AND MAY BE A BURN HAZARD.

C A U T I O N

FIRE OR EQUIPMENT DAMAGE CAN RESULT FROM

IMPROPER SHORTENING LEVELS. THE LEVEL OF

SHORTENING MUST ALWAYS BE ABOVE THE HEATING

ELEMENTS WHEN THE FRYER IS OPERATING.

THE REQUIRED SHORTENING LEVEL MUST ALWAYS

BE ABOVE THE MINIMUM HOT OIL FILL LINE.

D A N G E R

The flash point of shortening

occurs at a lower temperature

the longer the shortening is

used. Discard any shortening

showing signs of deterioration

to avoid serious burns, fire,

and property damage.