Cleaning guide, Calibrator safety guidelines – Campbell Scientific PWC100 Present Weather Sensor Calibrator User Manual

Page 16

PWC100 Present Weather Sensor Calibrator

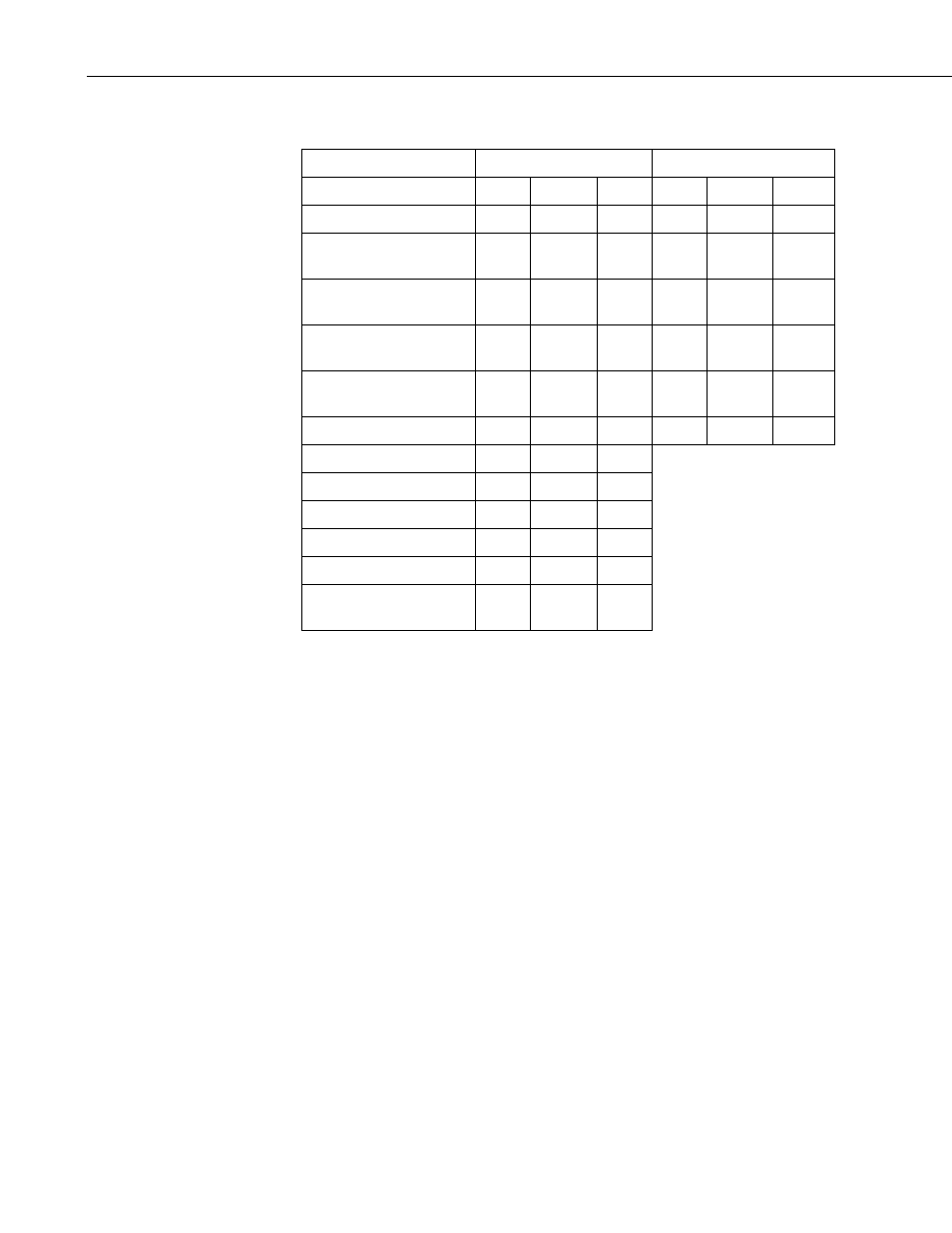

Quick look LED status table

Ready/complete state

Running state

Test

state

Left Center Right Left Center Right

Visibility

test

Flash

Flash

ON

ON

Visibility maximum

range test

Flash Flash

ON ON

Velocity test position 1

(Center)

Flash

ON

Velocity test position 2

(Left)

Flash

ON

Velocity test position 3

(Right)

Flash

ON

Final result states

Calibration passed

ON

ON

ON

Calibration required

Flash

Flash

Flash

Error conditions

Fault occurrence during

tests

Flash

Flash

4. Cleaning Guide

It is important to ensure that the visibility and velocity disks are clean prior to

use. Finger prints and small quantities of dust should not impair performance

significantly, but it is highly recommended that the disks are kept clean and

care is taken to ensure the surfaces are not scratched, cracked or damaged. A

cleaning agent that does not leave a residue such as isopropyl alcohol or a

product specifically designed to clean optical equipment should be used along

with a lint free cloth.

5. Calibrator Safety Guidelines

During the velocity tests, the calibration disk will be rotated at a moderate

speed.

It is recommended that the user visually checks the disk for any cracks or

distortions on its surface. If the disk is cracked or distorted in any way, the

tests should not be performed as this may cause an incorrect result or even

damage to the calibration unit. Campbell Scientific should be contacted for

advice about any damage that may have occurred to the disk.

When performing the tests, the operator should stand more than two meters

from the calibrator. This prevents the operator from interfering with the results

by causing reflections, and keeps the operator away from the rotating disk.

10