Ashcroft EL - Industrial Bimetal Thermometer User Manual

Installation, Method of selecting the set, Type 91 series adapter kit

INSTALLATION

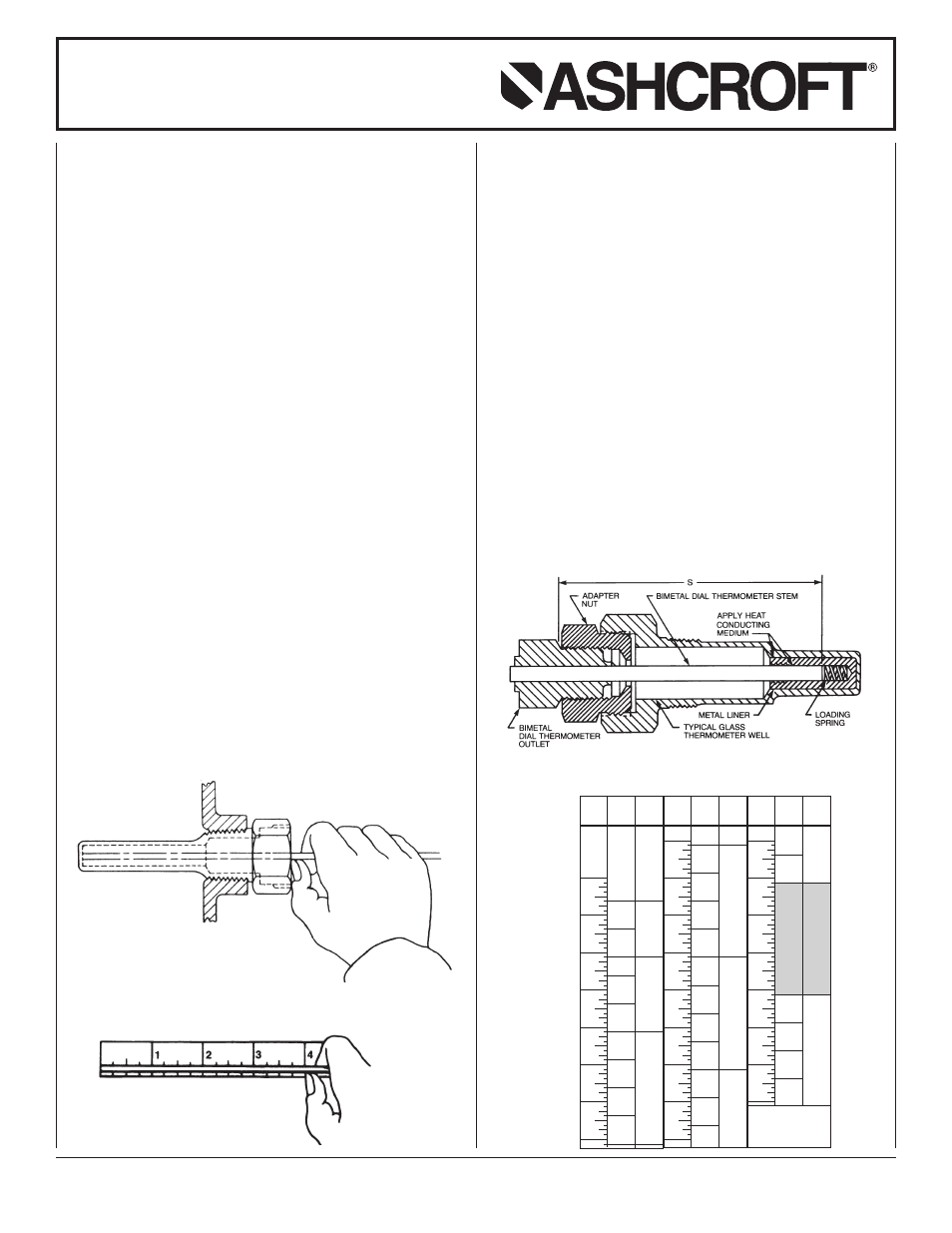

Assemble the adapter nut into the well and tighten se-

curely. (See Figure 3.)

Before installing the Bimetal Dial Thermometer into the

adapter and well, coat the lower 3˝ section of the ther-

mometer with a layer of heat conducting medium. This

will improve the temperature response of the ther-

mometer.

The metal liner is then slipped over the end of the

thermometer stem and a coating of heat conducting

medium is applied to the outside wall of the liner.

The thermometer and the liner are then inserted into

the well and tightened in position. Do not tighten more

than is necessary to prevent the thermometer from

turning.

Where service temperatures exceed 350°F the heat

conducting medium may smoke when first subjected

to a high temperature. This is caused by the vehicle, in

the heat conducting medium, vaporizing and leaving

the dry solids behind. This should not be cause for

alarm. The dry solids will act equally well as a heat

conducting medium for temperatures up to 1000°F.

The Type 91 Series Adapter Sets were designed to

provide a simple means of installing a bimetal dial

thermometer into an existing industrial glass ther-

mometer well.

The adapter set consists of:

1. A metal liner and spring assembly.

2. An adapter nut.

3. A small supply of heat conducting medium.

METHOD OF SELECTING THE SET

The Adapter Sets are available in four different sizes,

to cover various depths of wells. The “Selection Chart”

shows the Adapter Set number and the Bimetal Dial

Thermometer stem length to use for any well depth

from 3

5

⁄

8

˝ up to 25

1

⁄

8

.˝

To select the proper Adapter Set and Bimetal Dial

Thermometer stem length, measure first the well

depth by inserting a pencil, or any small diameter rod

or stiff wire until it reaches the bottom. (See Figure 1.)

Be sure the rod does not hang up on any shoulder in-

side the well. Using your thumb as an index, withdraw

the rod and measure the distance from the end of the

rod to the index point. (See Figure 2.)

Then use the chart to select the Adapter Set and the

Bimetal Dial Thermometer stem length to fit the well.

Note that one stem length of thermometer covers several

different well depths by using the correct Adapter Set.

For example, a thermometer with a 9˝ long stem can

be used for well depths between 7

1

⁄

8

˝ and 10

1

⁄

8

,˝ by

choosing the correct Adapter Set.

The liner is tapped with a

5

⁄

16

-

˝ 18 machine thread so it

can be removed from the well if desired.

Figure 1

Figure 2

WELL

STEM

DEPTH

ADAPTER

LENGTH

IN

SET NO.

“S”

INCHES

3

4

91B

4

91A

5

91C

6

91B

6

91A

7

91D

8

91C

9

9

91B

91A

10

WELL

STEM

DEPTH

ADAPTER

LENGTH

IN

SET NO.

“S”

INCHES

10

91D

11

91C

12

12

91B

91A

13

91D

14

91C

15

15

91B

91A

16

91D

17

18

91C

18

WELL

STEM

DEPTH

ADAPTER

LENGTH

IN

SET NO.

“S”

INCHES

18

91B

18

91A

19

20

21

22

91D

23

91C

24

24

91B

91A

25

Figure 3

SELECTION CHART

Note: If the measured well

depth falls on the dividing line

between two stem lengths

and/or two Adapter Sets choose

the stem and/or Adapter Set

above the line.

INSTALLATION AND MAINTENANCE

INSTRUCTIONS FOR ASHCROFT

®

TYPE 91 SERIES ADAPTER KIT

© 2011 Ashcroft Inc., 250 East. Main Street, Stratford, CT 06614-5145, USA Tel: 203-378-8281, Fax: 203-385-0499, www.ashcroft.com

All sales subject to standard terms and conditions of sale. I&M008-10004K-03/11