Burr King Model 85 User Manual

Page 11

See our catalog at

www.burrking.com

Contact us at

M254585opinst NEW 2009.doc - 12/30/2009

8

• Vibratory processing creates sludge in the liquid supply system. This sludge is a natural result of the

mechanical abrasion that occurs. The sludge may contain abrasive residue, part material residue, soap, or

other materials that you may introduce into the process. This sludge should be processed and discarded in a

manner that is acceptable to your local, and/or state environmental protection agencies. Since Burr King can

not know what materials a customer may introduce into the process, it cannot provide specific instructions

regarding this topic. Burr King can provide MSD

sheets for all media and chemical products that it

sells.

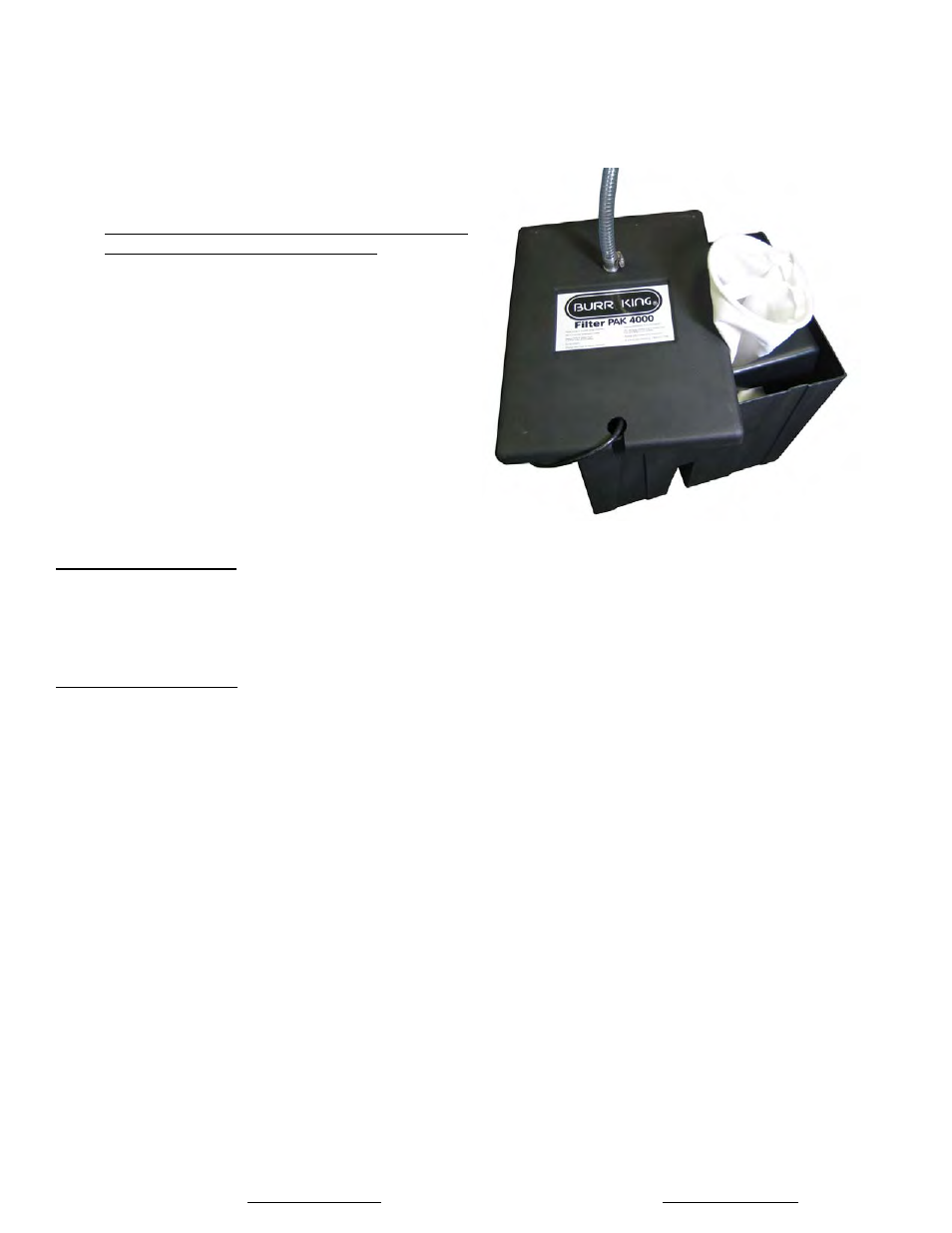

• Use a filtration system such as the Burr King

FilterPAK 4001 or FilterPAK 8000 to keep your

fluids cleaner too greatly minimize difficulty in

sludge disposal. The FilterPAK 4001 incorporates

inexpensive, disposable filter bags that trap sludge

for ready disposal. Of course the fluid that is

returned to your vibratory chamber is much cleaner.

Cleaner fluids mean cleaner parts, better finishes,

faster processing time, and naturally less mess in

your shop, and responsible waste management.

Many users who process aluminum, steel, iron,

copper, and other non toxic metals find that the

FilterPAK 4001 filter bags may be sent to public

land fills as normal refuse. Always consult with

your local authorities if you are in doubt about

proper waste disposal.

Discharging media/parts

The discharge chute is located on the lower portion of the machine left side. The chute plug may be removed by pulling if

free of the tub. With the machine operating, the media and parts (if smaller than the tube diameter) will cascade from the

tube to a container of you choice. NOTE: When the machine approaches empty it may begin to walk while vibrating.

Should this occur , switch main power switch to “off” and remove the balance of the media/parts manually.

Controlling rancid fluids

Vibratory fluids will accumulate organic contaminants from operators, parts, etc. The fluids may become rancid,

producing a foul smell. You can easily control rancidity by keeping your chamber, filter system, etc. clean. In the event of

rancidity add a small amount of “Lysol” disinfectant to the media while the machine is operating. Ordinarily, a couple of

tablespoons full will work very well and not adversely effect your vibratory processing. In fact, many metal react

favorably with “Lysol” by finishing to a brighter level.