Burr King Model 960-272 User Manual

Page 12

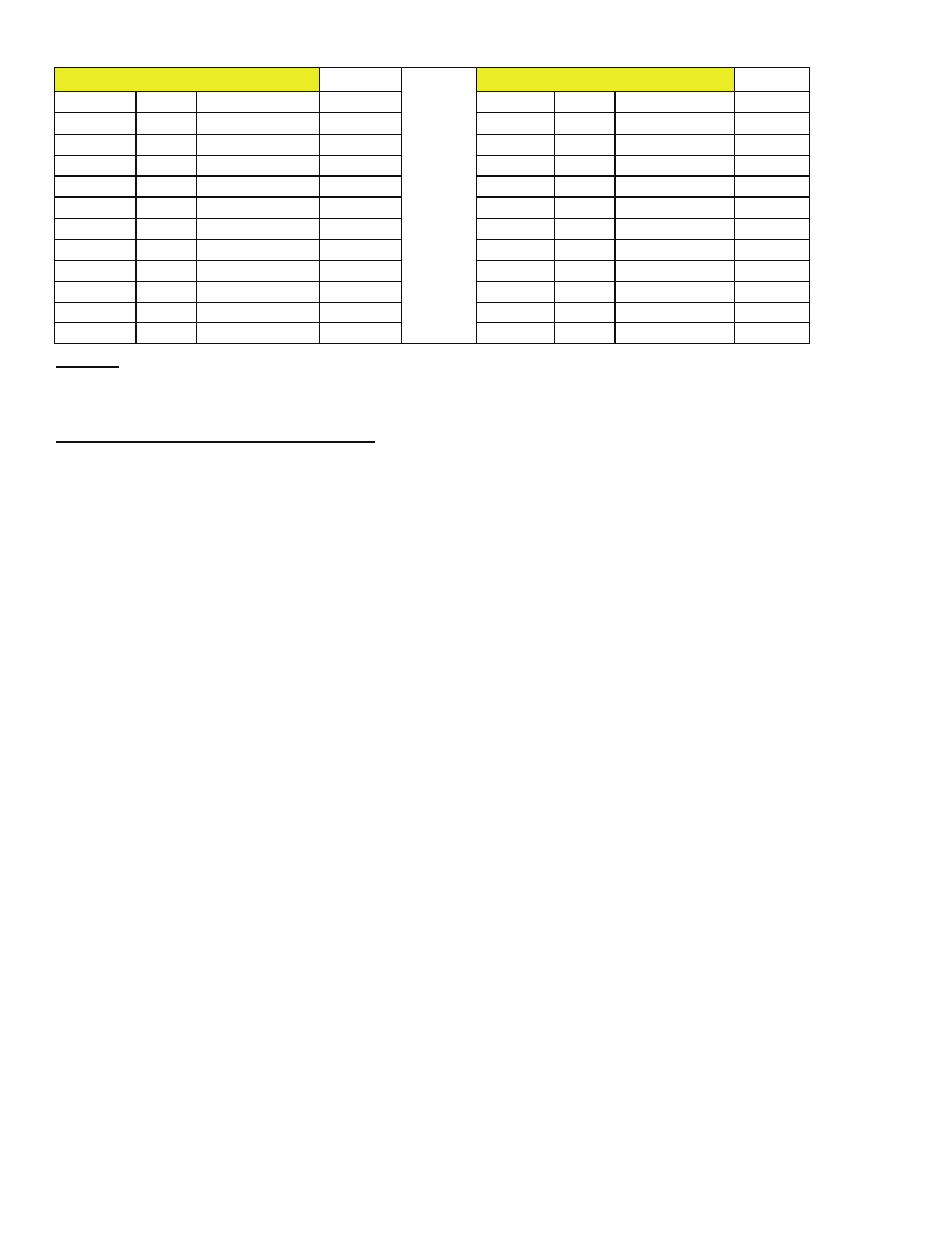

Model 960-272 6200 SFPM

Meters

Model 960-272 7000 SFPM

Meters

Percent

SFPM

Spindle RPM

SMPM

Percent

SFPM

Spindle RPM

SMPM

100.00%

6200

2962 1889.76

100.00%

7000

2962 2133.6

90.00% 5580

2665.8 1700.784

90.00%

6300

2665.8 1920.24

80.00% 4960

3312 1511.808

80.00%

5600

3312 1706.88

70.00% 4340

2898 1322.832

70.00%

4900

2898 1493.52

60.00% 3720

2484 1133.856

60.00%

4200

2484 1280.16

50.00% 3100

2070 944.88

50.00%

3500

2070 1066.8

40.00% 2480

1656 755.904

40.00%

2800

1656 853.44

30.00% 1860

1242 566.928

30.00%

2100

1242 640.08

20.00% 1240

592.4 377.952

20.00%

1400

592.4 426.72

10.00%

620 437 188.976

10.00%

700 437 213.36

0.00%

620 437 188.976

0.00% 700

437

213.36

Fig 3.6

Maintenance of the model 960-272

•

Every thirty days apply light machine oil to the rear wheel support to rear wheel handle interface. Two drops of oil is sufficient.

•

Every thirty days check the drive belt tension. If you can hear the belt “slap” the frame when the drive motor starts, the belt may

require re-tensioning. Do this by loosening the two nuts that secure the motor to the belt guard and slide the guard forward. Do

not over tighten the belt. Doing so will shorten the life of the machine bearings. Tighten the two nuts.

•

Routinely inspect the machine for loose hardware. Tighten as required.

•

Daily vacuum or otherwise remove dust and debris build-up from the machine and the machine belt track.

There are no other maintenance actions required. All bearings are sealed for life and require no additional lubrication.

Burr King Manufacturing can help you with problem solutions, and/or answers to your questions. Please call your Burr King

distributor first; if you can not reach satisfactory conclusion please call the Burr King factory.