Important safety information, Danger of death, Risk of fire – Siemens LI18030 User Manual

Page 6: Risk of injury, Risk of electric shock, Danger of suffocation, General information, Exhaust air mode, Note, Exhaust duct

en

Ú

Installation instructions

Important safety information

Read these instructions carefully. Only then will you be able to

operate your appliance safely and correctly. Retain the

instruction manual and installation instructions for future use or

for subsequent owners.

The appliance can only be used safely if it is correctly installed

according to the safety instructions. The installer is responsible

for ensuring that the appliance works perfectly at its installation

location.

The width of the extractor hood must correspond at least with

the width of the hob.

For the installation, observe the currently valid building

regulations and the regulations of the local electricity and gas

suppliers.

:

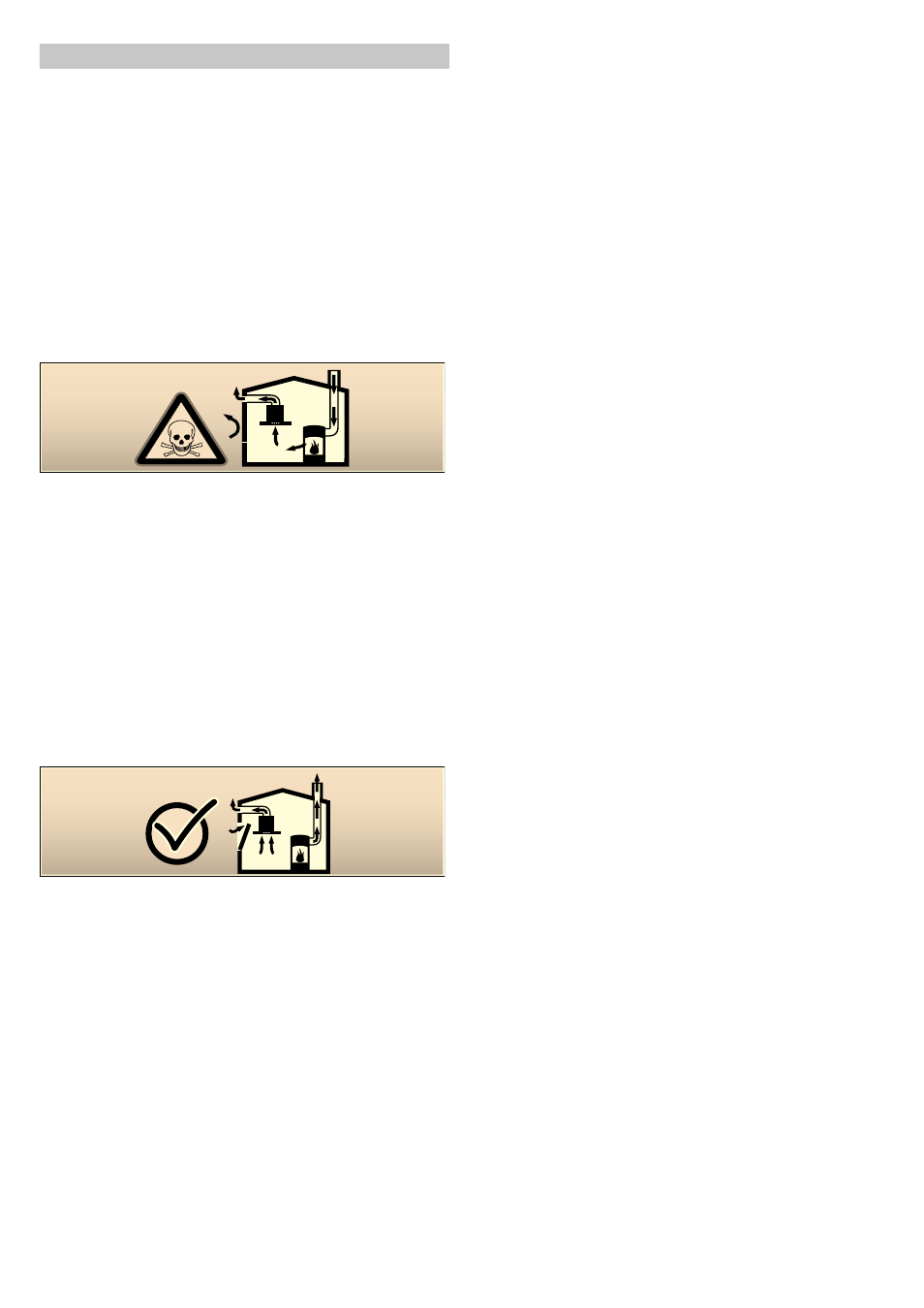

Danger of death!

Risk of poisoning from flue gases that are drawn back in.

Always ensure adequate fresh air in the room if the appliance is

being operated in exhaust air mode at the same time as room

air-dependent heat-producing appliance is being operated.

Room air-dependent heat-producing appliances (e.g. gas, oil,

wood or coal-operated heaters, continuous flow heaters or water

heaters) obtain combustion air from the room in which they are

installed and discharge the exhaust gases into the open air

through an exhaust gas system (e.g. a chimney).

In combination with an activated vapour extractor hood, room air

is extracted from the kitchen and neighbouring rooms - a partial

vacuum is produced if not enough fresh air is supplied. Toxic

gases from the chimney or the extraction shaft are sucked back

into the living space.

■

Adequate incoming air must therefore always be ensured.

■

An incoming/exhaust air wall box alone will not ensure

compliance with the limit.

Safe operation is possible only when the partial vacuum in the

place where the heat-producing appliance is installed does not

exceed 4 Pa (0.04 mbar). This can be achieved when the air

needed for combustion is able to enter through openings that

cannot be sealed, for example in doors, windows, incoming/

exhaust air wall boxes or by other technical means.

In any case, consult your responsible Master Chimney Sweep.

He is able to assess the house's entire ventilation setup and will

suggest the suitable ventilation measures to you.

Unrestricted operation is possible if the vapour extractor hood is

operated exclusively in the circulating-air mode.

:

Danger of death!

Risk of poisoning from flue gases that are drawn back in. If

installing a ventilation system in a room with a heat-producing

appliance connected to a chimney/flue, the electricity supply to

the hood must be equipped with a suitable safety switch.

:

Risk of fire!

Grease deposits in the grease filter may catch fire. The specified

safety distances must be observed in order to prevent an

accumulation of heat. Observe the specifications for your

cooking appliance. If gas burners and electric hotplates are

operated together, the largest specified distance applies.

:

Risk of injury!

■

Components inside the appliance may have sharp edges.

Wear protective gloves.

Risk of injury!

■

The appliance may fall down if it has not been properly

fastened in place. All fastening components must be fixed

firmly and securely.

Risk of injury!

■

The appliance is heavy. To move the appliance, 2 people are

required. Use only suitable tools and equipment.

:

Risk of electric shock!

Components inside the appliance may have sharp edges. These

may damage the connecting cable. Do not kink or pinch the

connecting cable during installation.

:

Danger of suffocation!

Packaging material is dangerous to children. Never allow

children to play with packaging material.

General information

Exhaust air mode

Note: The exhaust air must not be conveyed into a functioning

smoke or exhaust gas flue or into a shaft which is used to

ventilate installation rooms which contain heat-producing

appliances.

■

Before conveying the exhaust air into a non-functioning smoke

or exhaust gas flue, obtain the consent of the heating

engineer responsible.

■

If the exhaust air is conveyed through the outer wall, a

telescopic wall box should be used.

Exhaust duct

Note: The appliance manufacturer does not assume any

warranty for complaints attributable to the pipe section.

■

The appliance achieves its optimum performance by means of

a short, straight exhaust air pipe and as large a pipe diameter

as possible.

■

Because of long rough exhaust air pipes, many of which are

pipe bends or have diameters smaller than 150 mm, the

optimum extraction performance is not achieved and fan

noise is increased.

■

The pipes or hoses for laying the exhaust duct must consist of

non-combustible material.

Round pipes

An inner diameter of 150 mm, but at least 120 mm, is

recommended.

Flat ducts

The inner cross-section must correspond to the diameter of the

round pipes.

Ø 150 mm approx. 177 cm

2

Ø 120 mm approx. 113 cm

2

■

Flat ducts should have no sharp deflections.

■

Use sealing strip for deviating pipe diameters.

Electrical connection

:

Risk of electric shock!

Components inside the appliance may have sharp edges. These

may damage the connecting cable. Do not kink or pinch the

connecting cable during installation.

The required connection data can be found on the rating plate

inside the appliance; to do this, remove the metal mesh grease

filter.

Length of the cable: approx. 1.30 m

This appliance complies with the EC interference suppression

regulations.

This appliance may be connected to a correctly installed

earthed socket only.

Fit the earthed socket as far inside the fitted unit as possible.

■

The earthed socket should be connected via its own circuit.

■

If the earthed socket is no longer accessible following

installation of the appliance, a disconnector must be fitted as

for a permanent connection.

If a permanent connection is required, the installation must

feature an all-pole disconnecter (circuit breakers, fuses and

contactors) with a min. 3 mm contact opening. The permanent

connection may be installed by an electrician only.