Blade selection – Dake Model 14-10 User Manual

Page 5

7/22/03

Model 14-10

5

Blade Selection

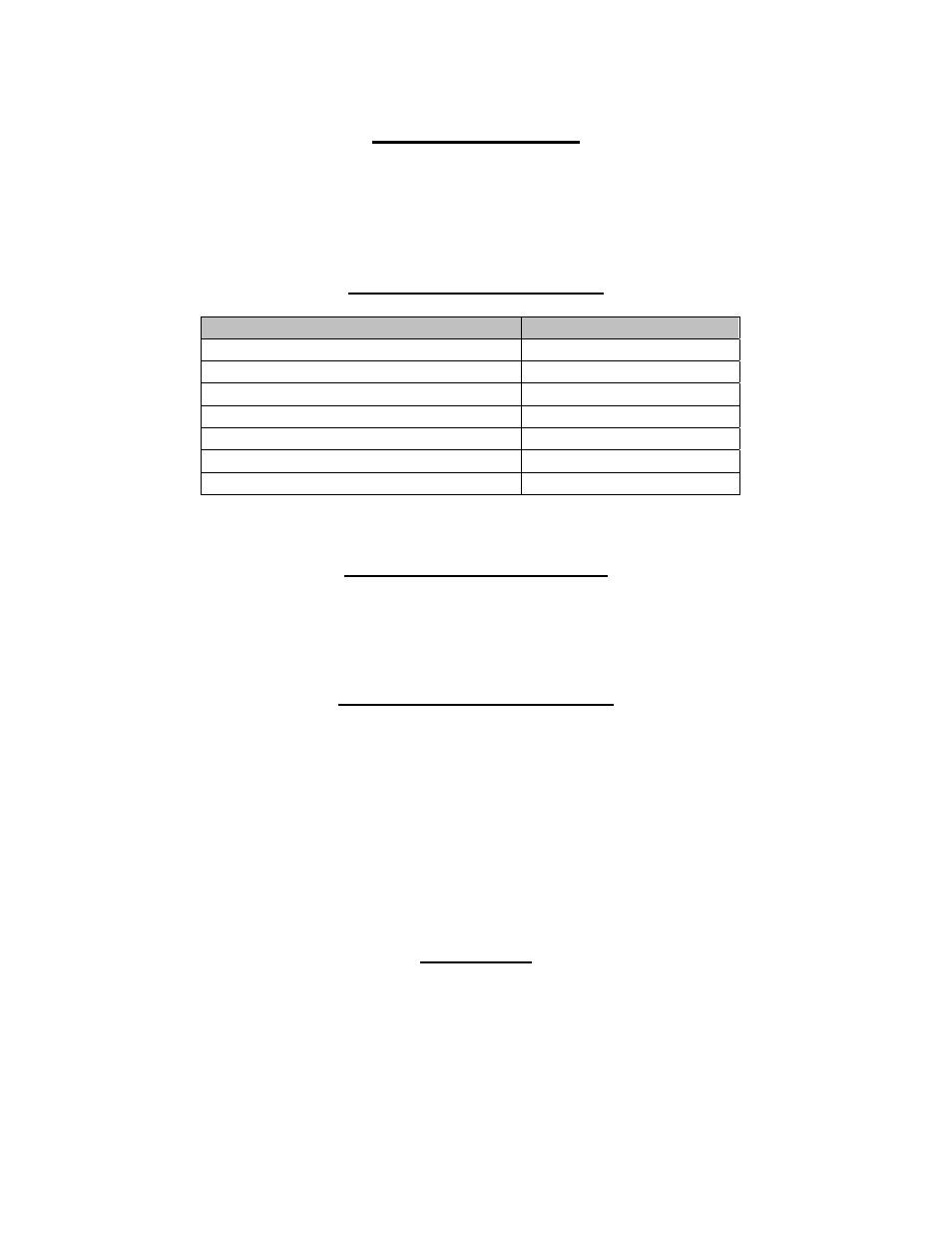

For Operator convenience, a blade selector chart is located inside the saw

cover. It provides recommended blade speeds, required teeth per inch,

and minimum cutting radius for various blade widths. The following chart

can be used to select the blade needed:

Standard Tooth Applications

Thickness of Material

Teeth per Inch

Up to 1/8”

18 Teeth

1/8” to 1/4"

14 Teeth

1/4" to 1/2"

10 Teeth

1/2" to 1”

8 Teeth

1” to 3”

6 –4 Teeth

3” to 6”

4-6 Teeth

6” and longer

3H

Note: 1) You must have at least 3 teeth into your work or blade damage will result.

2) For straight cuts, a 3/4" inch blade is best.

Blade Speed (feet per minute)

To change blade speeds, lift the motor and move the v-belt to one of the

three speeds offered: 70/140/270/540. Refer to the blade selector chart

inside the cover on your 14-10 for the appropriate speed.

Blade Removal and Installation

To remove the blade, release the blade tension handle. (Item A on page

4). Remove the blade.

To install the blade, place the blade over the bottom wheel, then on the

top wheel. Teeth must point down toward the table. Tighten the blade

tension handle enough to hold the blade firmly in place, and the push the

blade into the guide inserts. Turn the machine on to allow the blade to

position itself and then finish tightening the blade. IMPORTANT: Blade

must be tight to insure straight cut.

Please Note:

The most common causes for your 14-10 not cutting straight are:

1) Blade tension is too low.

2) The blade is either dull or worn on one side.

3) The blade is upside down. The teeth must point down toward

the table.