Hydraulic vertical boom adjustment sprayers, Important – Summers 3Pt Supersprayer User Manual

Page 20

14

SECTION 3 - SPRAYER OPERATION

HYDRAULIC VERTICAL BOOM ADJUSTMENT SPRAYERS!

VERTICAL BOOM HEIGHT MUST NOT BE ACTIVATED WITH THE BOOMS IN THE FOLDED POSITION OR

DAMAGE TO SPRAYER WILL RESULT. VERTICAL ADJUSTMENT MUST ONLY BE PERFORMED WITH THE

BOOMS IN FIELD POSITION.

IMPORTANT!

BEFORE ACTIVATING SPRAY PUMP HYDRAULIC SYSTEM VERIFY DIRECTION OF OIL FLOW IS CORRECT. OIL

MUST FLOW INTO THE PRESSURE PORT OF HYDRAULIC MOTOR. THIS CAN BE CHECKED BY MOMEN-

TARILY ACTIVATING THE HYDRAULIC SYSTEM. THE HOSE LEADING TO THE PRESSURE PORT SHOULD

FLEX OR STIFFEN WHEN SYSTEM IS ACTIVATED. IF WRONG HOSE FLEXES, EITHER REVERSE HOSES AT

THE TRACTOR OUTLET OR MOVE HYDRAULIC LEVER IN OPPOSITE DIRECTION. A CHECK VALVE INSTALLED

ON THE TANK SIDE OF THE MOTOR PREVENTS OIL FROM FLOWING THROUGH THE MOTOR IN THE WRONG

DIRECTION.

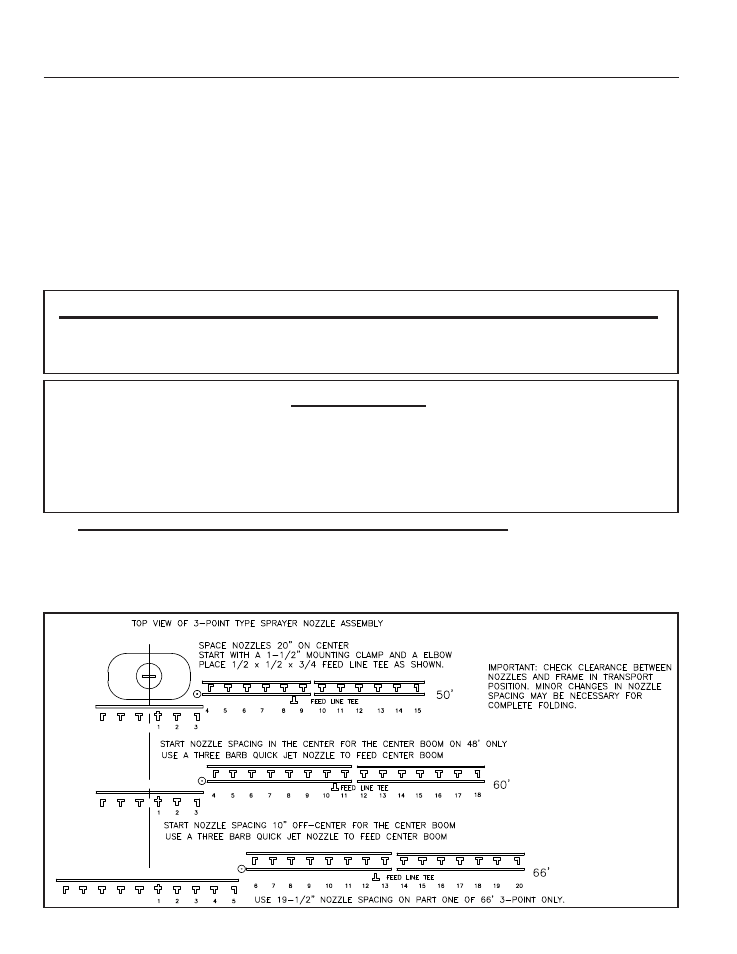

5. 50 TO 60, AND 66 FOOT 3-POINT DRY BOOM SPRAYERS NOZZLE SPACING

Nozzle spacing for the Summers dry boom 3-Point sprayers is at 20 inches with equal distance from sprayer center line. The

first nozzle is 10 inches from the sprayer centerline on rear boom. Nozzle spacing for the 66 foot Summers dry boom 3-Point

sprayer is as follows. The first nozzle is 10 inches from the sprayer centerline on rear boom. Nozzles on the first section of

boom are spaced evenly at approximately 19-1/2” beginning with a 19-1/2” spacing from last nozzle on center boom to first

nozzle on first boom section. On second boom section all remaining nozzles are spaced in 20 inch increments.

valves. Consult with your tractor manufacturer to determine if you have this type of system and require an orifice. Further

information is available with your pump’s operating manual.

Hypro hydraulic motors are equipped with a bypass adjustment screw. These are only to be adjusted when used on Open

Center hydraulic systems. Please see the installation instructions included with the pump for directions on how to use the

bypass. Closed Center hydraulic systems do not require any bypass. Be sure that the bypass adjustment is screwed all the

way in and the lock nut is tight when operating on Closed Center systems.

There are four basic positions for each type of spool valve. They are Raise, Neutral, Lower, and Float (in order, from back to

front). The names used for these positions vary somewhat between manufacturers, but the order of the positions do not.

To properly operate a hydraulic motor-driven centrifugal pump on a tractor hydraulic circuit, only the Lower and Float positions

should be used. Use Lower for “On” and Float for “Off”. The Float position is recommended for turning the motor off because

it allows the remote circuit to flow in a continuous loop allowing the motor to free wheel to a stop and also does not trap

pressure in the circuit.