Caution – Bloom Manufacturing 1400 Series User Manual

Page 6

Section 5

Speed Reducer Installation

• To must make sure that your speed Reducer is securely mounted in order for it to

function properly and to ensure safe operation.

• The mount must be flat to ensure proper alignment of the gearbox.

• Speed Reducers must never be fastened directly to the frame of a truck Mounting

• Speed Reducers must never be fastened directly to the frame of a truck. Mounting

brackets should be used.

• With a hydraulically driven Speed Reducer, make sure the hydraulic system is clean

and that all components function properly, especially the relief valve.

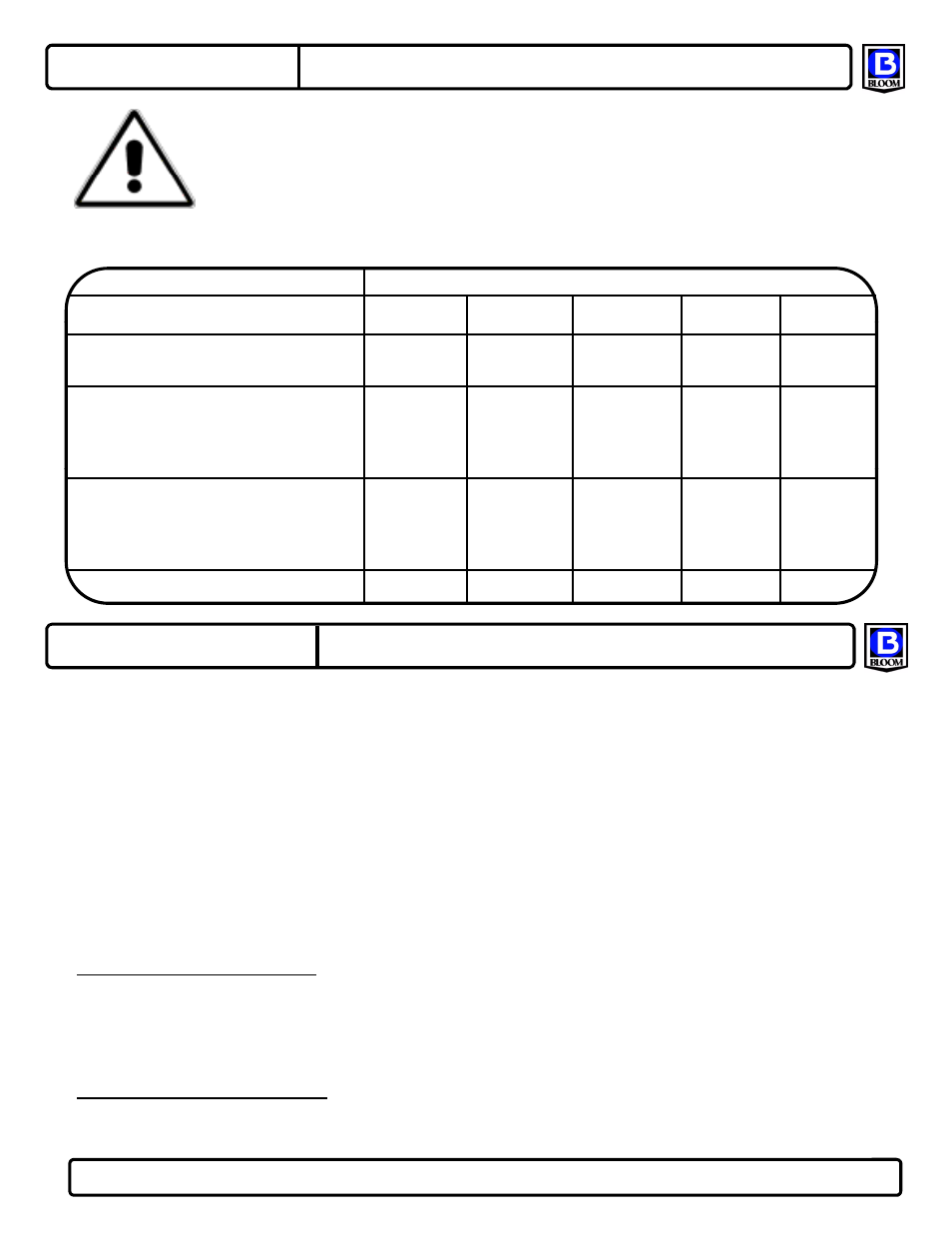

Speed Reducer Series

800 1000

1100

1200

1400

Hardware Requirements

CAUTION

800 1000

1100

1200

1400

Base Mount (steel)

Thickness

Angle Mounts (steel)

Length

Width

Thickness

1”

3”

3”

1/2”

1/2”

2-1/2”

2-1/2””

1/4”

1/2”

2-1/2”

2-1/2””

1/4”

1/2”

2-1/2”

2-1/2””

1/4”

a d a e equ e e ts

1/2”

2-1/2”

2-1/2””

1/4”

Thickness

Capscrews (Hexhead)

Size

Thread

Grade

Torque / Tightening (foot pounds)

5/8”

11 UNC

5

112

1/2”

13 UNC

5

57

1/2”

13 UNC

5

57

1/2”

13 UNC

5

57

1/2”

13 UNC

5

57

Section 6

Speed Reducer Operation

• To familiarize yourself with the Speed Reducer, run it for a few minutes to understand the controls and the “feel” of the

Speed Reducer. Pay particular attention to the controls and how they operate.

• Make sure you understand which way the Speed Reducer will rotate when the control lever is moved.

Always make sure that all people are clear of the load before beginning a Speed Reducer operation

• Always make sure that all people are clear of the load before beginning a Speed Reducer operation.

• Do Not attempt to defeat the relief valve.

(a) Automatic Safety Brake

Some Bloom Speed Reducers are equipped with an automatic hydraulic brakes to hold suspended loads. If your

Speed Reducer is not equipped with one, it is intended for pulling loads only. If you wish to lift and suspend loads with

your Speed Reducer, it can be retrofitted with a brake. Please consult the factory for details. The safety brake is an

important feature of your Speed Reducer and must be maintained properly There are two types of brakes used on

important feature of your Speed Reducer and must be maintained properly. There are two types of brakes used on

Bloom Speed Reducers:

Adjustable Automatic Safety Brake (Drag)

An oil cooled automatic safety brake disengages when a load is lifted or moved forward and automatically engages

when power is removed or the load is lowered or if the load tries to roll backward. IT IS EFFECTIVE IN ONLY ONE

DIRECTION. Make sure the braking action is taking place in the correct rotation. See instruction for; “Assembly

Instructions Oil Cooled Adjustable Automatic Safety Brake”

Instructions, Oil Cooled Adjustable Automatic Safety Brake .

Automatic Hydraulic Fail-Safe Brake (Spring applied hydraulic release)

Spring applied hydraulic release brake automatically holds load when hydraulic pressure is released. Double counter

balance valve adds additional load holding capability by locking hydraulic oil in motor.

6

Bloom Mfg Inc. 319-827-1139 319-827-1140 fax www.bloommfg.com