Akiles iWire User Manual

Akiles Equipment

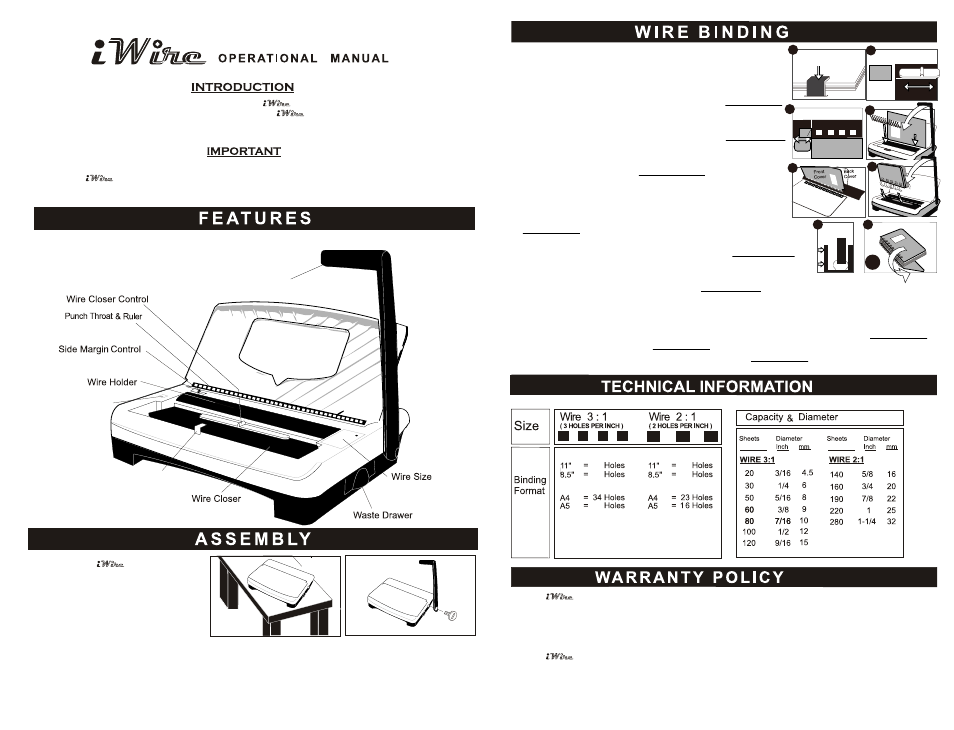

Punch and Closer Handle

Diameter Selector

PAPER

11”

3/16”

Wire Closer Control

Side Margin Control

3/16”

2.

3.

4.

1.

PAPER

SET-UP INTRUCTIONS (STEPS 1-4a)

1) Based on document thickness you must first determine the

optimal wire diameter size needed. To do this, insert your full

unbound document into the Diameter Selector. See picture 1

2) Next, based on the selected wire diameter size, pre-set the

Wire Closer opening. To do so, slide the Wire Closer Control

to the matching wire diameter size on window. See picture 2.

3) Based on document length, you must now adjust the side

margin for an evenly centered punch. To do so, press and

slide Side Margin Control. See Picture 3.

Hint: We recommend for you to test punch some waste

paper and readjust the Side Margin Control as needed.

4a) Insert selected wire element into wire holder. Doing so will

allow for easier insertion of sheets after each punch.

See picture 4

PUNCHING & CLOSING (STEPS 4b-7)

4b) Insert sheets and pull handle forward to punch. See picture 4

Important: Make sure sheets are fully inserted and slid against

the side margin.

5) Insert pages into wire element as shown. See picture 5

Hint: Insert document pages facing up from last to first, then insert front cover, then insert back

cover (inside of back cover should be facing up).

6a) Release the wire element along with your inserted sheets from the wire holder. Place document

to be bound inside wire closer with the opening of the wire element facing down. See picture 6

6b) Pull handle forward to close. See picture 6

7) Remove bound book & flip back cover to close book. See picture 7

Letter Size Paper

Wire Holder

WE RECOMMEND THAT YOU TAKE A FEW MINUTES TO FAMILIARIZE YOURSELF WITH THE FUNCTIONS OF

YOUR NEW . YOU WILL FIND THAT WITH JUST A LITTLE PRACTICE, ANY PERSON CAN

ACHIEVE PROFESSIONAL RESULTS.

CONGRATULATIONS ON THE PURCHASE OF YOUR NEW

, A MODERN, PRACTICAL AND RELIABLE

PUNCH AND BINDING MACHINE FOR WIRE BINDING. YOUR

WAS DESIGNED WITH

A FULL RANGE OF FUNCTIONS AND PREMIUM QUALITY COMPONENTS TO GUARANTEE AN

EFFORTLESS AND PROFESSIONAL BIND AS WELL AS MANY YEARS OF TROUBLE-FREE SERVICE.

1.Place your new on top of a sturdy

work table.

2.Remove the screw from punch axle

counter clockwise as indicated, connect

the punch handle in a vertical position

onto the punch

axle. Tighten-back the

screw clockwise.

Wire Size Selector

Wire Closure Scale

Scale

17

21

25

25

32

1.

2.

Y O UR

HA S A WA RRA NTY O F O NE Y E A R FRO M DATE O F P URCHA S E . IN THE E V E NT O F A

MA NUFA CTURE R'S DE FE CT, Y O UR DIS TRIB UTO R (AT O P TIO N) WIL L RE PA IR O R RE P L A CE IT.

IMP O RTA NT: THIS WA RRA NTY DO E S NO T CO V E R DA MA G E S DUE TO IMP RO P E R US E O R MIS S

TRE ATME NT O F THE UNIT, INCL UDING A NY E X TRA O RDINA RY E V E NT L E A DING TO THE DA MA G E O F

THE MA CHINE , WHE THE R IT IS RE V E RS IB L E O R NO T.

IF THE

IS NO T WO RK ING P RO P E RLY, FIRS T FO L L O W THE CO RRE CTIV E A CTIO NS A B O V E . IF

THE P RO B L E M P E RS IS TS , P L E A S E CO NTA CT Y O UR DE A L E R FO R FURTHE R INS TRUCTIO NS . P L E A S E

HAV E Y O UR MA CHINE 'S S E RIA L NUMB E R A ND THE P URCHA S E DATE RE A DY. IF THE MA CHINE MUS T

B E RE TURNE D TO Y O UR DIS TRIB UTO R, IT IS Y O UR RE S P O NS IB IL ITY TO P RO P E RLY PA CK A ND S HIP

IT, A S A NY DA MA G E S INCURRE D DURING ITS TRA NS P O RTATIO N A RE NO T CO V E RE D B Y O UR

WA RRA NTY P O L ICY.

( 20 lbs )

( 20 lbs )

Wire Closer

5.

6.

ok

6.

7.