Power Jacks Spiracon™ User Manual

Page 3

POWER JACKS LTD

DOCUMENT

Spiracon

Tel: +44 (0) 1358 285100

ISSUE No

1.4

email: [email protected]

PAGE

3 of 4

http://www.powerjacks.com

_________________________________________________________________________________

When installing the Spiracon roller screw ensure that the alignment of the screw in its

support bearings is within 0.1/1000.

Once the Spiracon roller screw is installed clean the screw thoroughly and lightly coat

with grease applied with a paintbrush. Note that the screw will be supplied either lightly

coated with grease or if supplied un-greased, coated with Shell ENSIS Fluid. The Shell

ENSIS Fluid can be removed with Shell Cleanforce or other hydrocarbon solvent.

If travel limit switches are fitted to the installation, set the travel switches to operate at

the required travel to ensure that the Spiracon roller nut cannot be driven into a solid

stop.

It is recommended that initial setting of proximity switches is carried out by manually

rotating the Spiracon roller screw to position the switch activators correctly.

WARNING - Do not operate the installed Spiracon roller screw until all travel limit

switches are commissioned.

Check that the grease nipple in the Spiracon roller nut is visible when the screw - nut is

installed.

5.0

MAINTENANCE

The Spiracon roller screw should not require maintenance during its normal life other

than;

5.1

The periodic injection of grease into the Spiracon roller nut through the grease access

hole provided, recommended six (6) monthly intervals minimum.

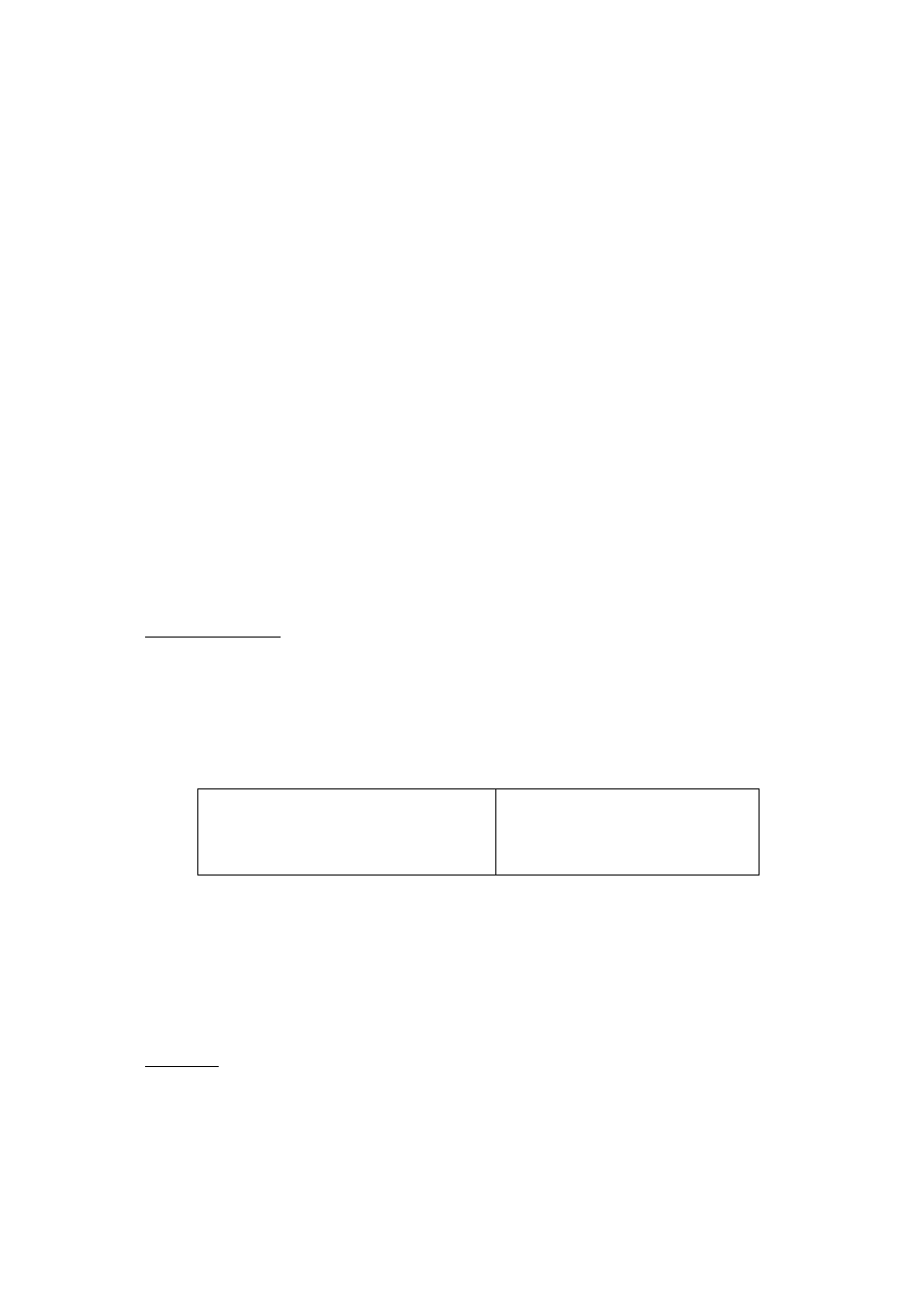

Spiracon Roller Nut & Screw

Rocol MTS 1000

Castrol Spheerol BM2

Shell Calithia HDX

Mobil Grease HP222

5.3

Periodic cleaning of the Spiracon roller screw and the re-application of a light coating of

grease applied with a paintbrush.

5.3

Should a repair to a Spiracon roller nut be required then remove the faulty Spiracon

roller nut, and return the unit to Power Jacks for repair.

6.0

WIPERS

There are two different types of wipers fitted to Spiracon nuts, a brush type and a

plastic type. The wiper, fitted to each end of the nut, retains the majority of the grease,

allowing a film of grease to remain on the screw thread, and prevents the ingression of

debris into the nut that may cause damage.