Metric series – ball screw jacks – Power Jacks E-Series - Ball User Manual

Page 8

8

Metric Series – Ball Screw Jacks

3.

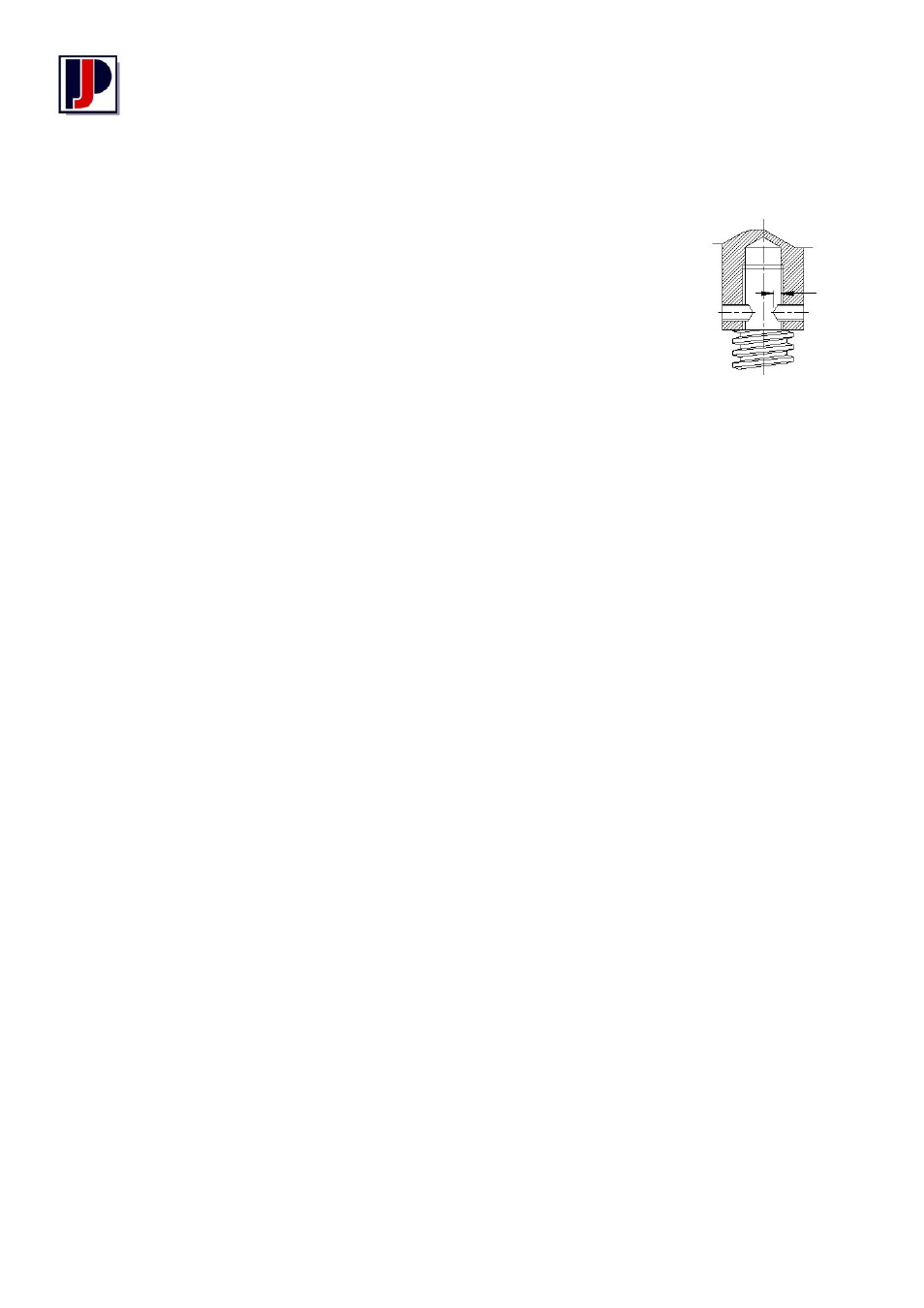

Fit the knurled point set screws (supplied with detachable ends) firmly in place ensuring that point of set

screws make contact with bottom of drill dimples. Secure the set screws with Loctite.

4.

If actuators with keyed lifting screws are involved, and it is required to line up

the clevis flats or top plate holes, etc., in a fixed relationship to the worm shaft

centreline, it will be necessary to face the underside of the detachable end to

obtain the required relationship. This operation should be done carefully as

only a few hundredths of a mm (thousands of an inch) removed from the

attachment is equivalent to a fair amount of rotational movement. After the

correct relationship has been obtained with the attachment firmly tightened up,

proceed as described in paragraphs 2 & 3.

6.2 Rotating Screw D.A.I.

IMPORTANT

Disassembly should be accomplished on a clean cloth. This is particularly important when

disassembling the ball nut assembly.

1. Remove any end fixture from the end of the ball screw (17).

2. Remove bottom pipe (22) or top cap (37).

CAUTION! It is very important the ball screw (17) not be allowed to run out of the ball nut (18). At

this point it is advisable to wrap tape round the last few ball screw threads to prevent this from

happening

3. To remove the ballscrew assembly (17 & 18) from the worm gear (16), first remove the lock nut (38)

with retaining grub screw (39) from the end of the ball screw (17).

4. Remove the ball screw guide bushing (4).

5. Ensure that shell cap set screws (27) are slackened back clear of drill dimples in shell (1) before

unscrewing shell cap (2). Note: it may be necessary to tap shell cap loose.

6. Remove the top load bearing from the shell cap (8).

7. On some models it will be necessary to remove the worm shaft (5) before the worm gear assembly can

be pulled clear of the shell. Take care not to lose the flange shims (10 & 11) if removing the worm shaft

assembly.

8. Check all parts for damage or excessive wear and replace where necessary. Note some ball screw and

nut assemblies (17 & 18) can be refurbished dependent on the extent of wear/damage.

9. After re-assembly of the worm shaft assembly, strike each end of worm sharply with a wooden or fibre

mallet to seat bearings properly. If new parts have been fitted it may be necessary to increase or

decrease the number of shims to obtain the correct endplay – the worm shaft should turn freely with the

minimum of endplay.

10. Press oil seals (13) into worm flanges (12) with the sealing members pointing inwards.

11. When re-assembling the worm gear and load bearings ensure that the bearings are fitted so that the

plate with the smallest bore size fits over the worm gear spigot.

12. The shell cap should be fitted after the worm shaft assembly has been securely clamped and with the

worm gear assembly in position. Tighten the shell cap until a slight drag is felt on rotating the worm

shaft by hand.

13. Tighten shell cap set screws (27). It may be necessary to drill new dimples in the shell if new parts have

been fitted or if re-adjustment for wear is necessary.

14. Attach the ball screw guide bushing (4).

15. Re-assemble the ball screw assembly (17 & 18) to the worm gearbox with lock nut (38) & retaining grub

screws (39).

16. Attach the bottom pipe (22) or top cap (37).

17. Re-assemble any end fixture to the ball screw (17).

1mm

deep

drill

dimples