Metric series – ball screw jacks, 3 general instructions, 4 recommended lubricants – Power Jacks E-Series - Ball User Manual

Page 4

4

Metric Series – Ball Screw Jacks

3 General

Instructions

3.1 Maintenance and Installation recommendations.

I

n order to ensure that the actuators give good service over a period of years the following precautions should be

taken.

3.1.1

Select an actuator which has a rated capacity greater than the maximum load that may be imposed on it.

3.1.2 The structure on which the actuators are mounted have ample strength to carry the maximum load, and

should be rigid enough to prevent undue deflection or distortion of the actuator supporting members.

3.1.3

It is essential that the actuators be carefully aligned during installation so that the lifting screws are

vertically true and the connecting shafts are exactly in line with the worm shafts. After the actuators,

shafting, gearboxes, etc., are coupled together it should be possible to turn the main drive by hand. If

there are no signs of binding or misalignment, the actuator system is then ready for normal operation.

3.1.4

The actuators should have a greater raise than is needed in the actual installation. Should it be

necessary to operate the actuators at the extreme limits of travel it should be done cautiously.

3.1.5

It is important that the lifting screws should not be closed below the specified closed height dimension of

the actuators, otherwise serious damage may result to the worm gear. Lifting screw end stops are to

prevent over-travel or loss of screw. These are not load supporting and should be treated as an

emergency device only and must not be allowed to come into contact with the worm gears during normal

working cycles otherwise serious damage will result to worm gears and bearings.

3.1.6

The maximum worm shaft speed for these actuators should not exceed 500 R.P.M. for heavy loads.

Refer to Power Jacks Limited for higher worm shaft speeds for lighter loads.

3.1.7

The lifting screws should not be permitted to accumulate dust and grit on the threads. If possible, lifting

screws should be returned to the closed height position when not in use.

3.1.8

The ball screw should be checked periodically for excessive backlash and spalling of raceways. Note all

Power Jacks Metric ball screw actuators have an integral safety device as standard in the ball nut.

Ball Nut Safety Device provides two important safety roles:-

3.1.8.1

In the unlikely event of excessive wear in the ball screw drive, the safety ring will contact the

screw shaft, and act as an “ACME” Thread. This will provide early warning of any possible ball

screw failure, and is capable of providing drive in the event of any such failure.

3.1.8.2

It allows the ball nut on the actuator to sustain a load in the event of catastrophic ball failure. The

safety of industrial and human cargo is therefore improved. Ball screw systems without this

device would collapse under load or drop the carried load.

3.1.9

The actuators are shipped packed with grease (unless otherwise called for) which should be sufficient for

one month of normal operation. For normal operation they should be lubricated about once a month

using one of the Extreme Pressure Greases or their equivalent. See “Recommended Lubricants” Table

1.

3.1.10 For severe service conditions the actuator should be lubricated with a molybdenium disulphide type of

grease about once a week. We recommend any of the greases indicated in “Recommended Lubricants”

Table 2.

4 Recommended

Lubricants

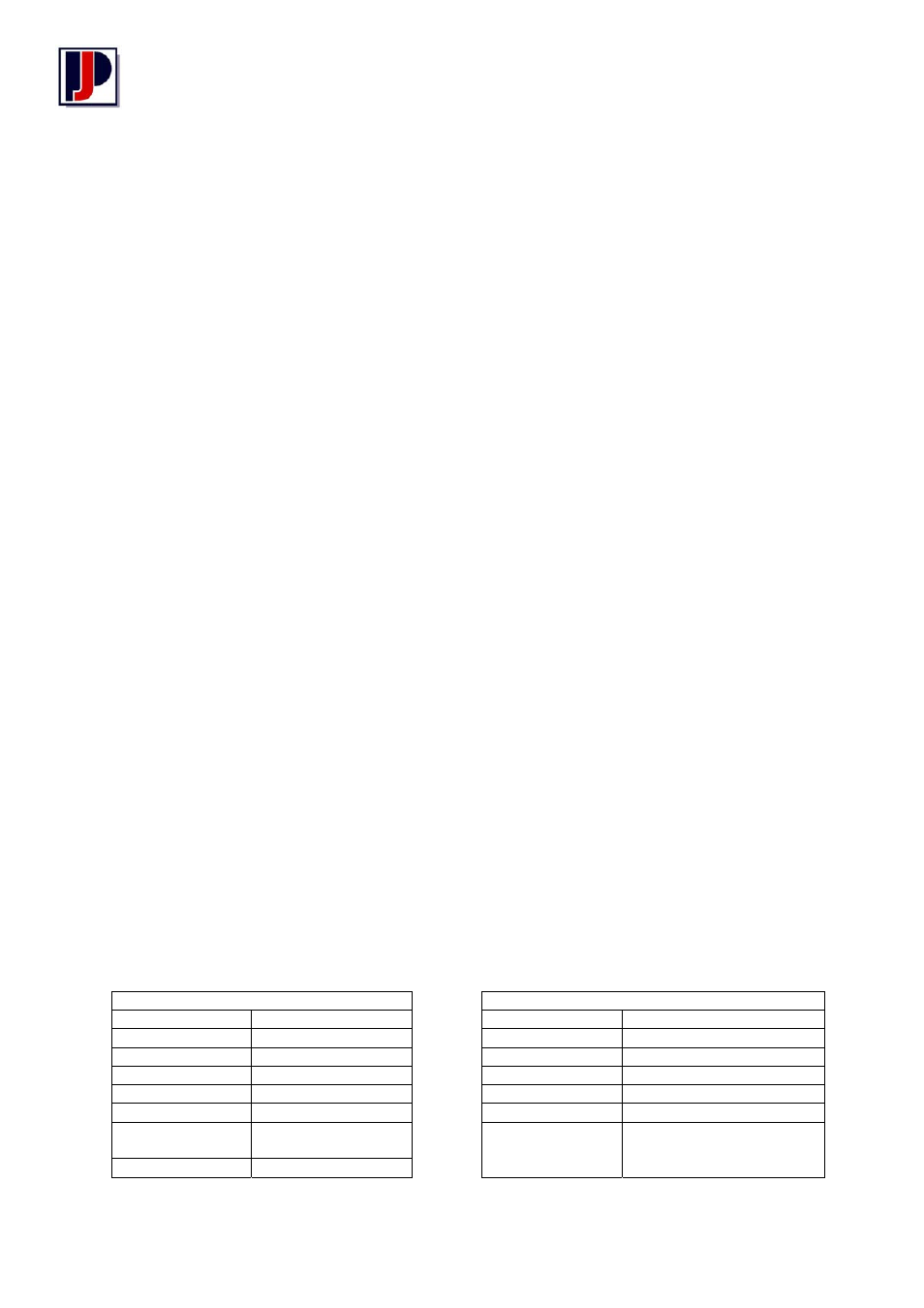

TABLE 1 – GREASE

TABLE 2 – GREASE

Manufacturer Lubricant

Manufacturer

Lubricant

Castrol Spheerol

EPL2

Castrol Spheerol

EPL2

Esso Beacon

EP2

Esso Beacon

Q2

Gulf Gulfcrown

EP2

Mobiloil

Mobilgrease

Special

Mobiloil

Mobilux EP2

Power Petroleum

BP Energrease L2 1M

Power Petroleum

BP Energrease LC2

Regent

Molytex 2

Regent

Texaco EP2

Shell

Shell Greases 5826

(Overseas)

Shell

Alvania WR2

Shell Alvania 2 + MoS

2