State GPH-90N User Manual

Page 16

16 www.statewaterheaters.com

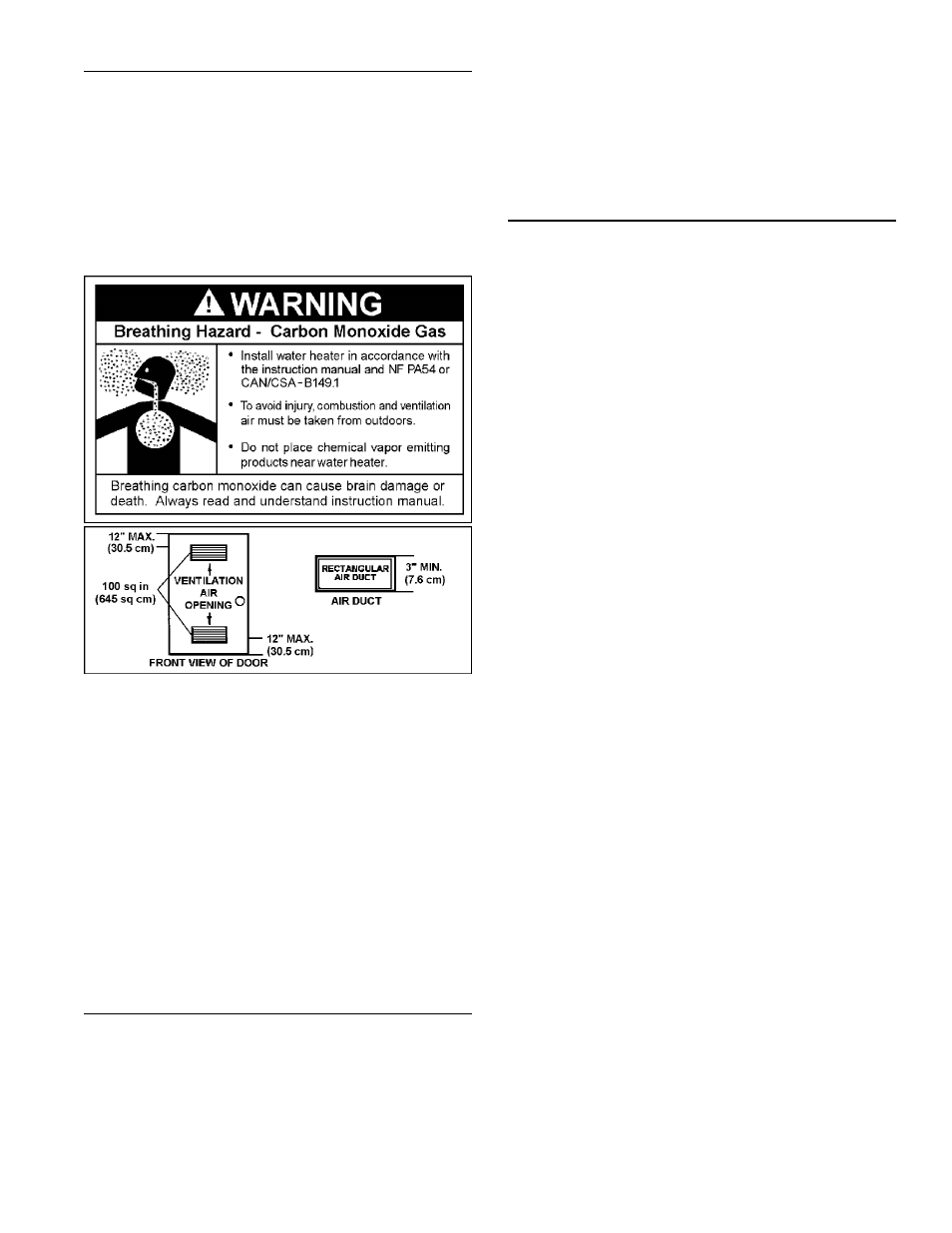

COMBUSTION AIR AND VENTILATION

A gas water heater cannot operate properly without the

correct amount of air for combustion. Do not install in a

confi ned area such as a closet, unless you provide air as

shown in the “Facts to Consider About Location” section.

Never obstruct the fl ow of ventilation air. If you have any

doubts or questions at all, call your gas supplier. Failure to

provide the proper amount of combustion air can result in

a fi re or explosion and cause death, serious bodily injury,

or property damage.

FIGURE 10

If this water heater will be used in beauty shops, barber

shops, cleaning establishments, or self-service laundries

with dry cleaning equipment, it is imperative that the water

heater(s) be installed so that all air for combustion and

ventilation is taken from outdoors.

Note: Vent length should be long enough that the outside

air will not freeze the water heater.

Propellants of aerosol sprays and volatile compounds,

(cleaners, chlorine based chemicals, refrigerants, etc.) in

addition to being highly fl ammable in many cases, will also

react to form corrosive hydrochloric acid when exposed to

the combustion products of the water heater. The results

can be hazardous, and also cause product failure.

APPLIANCES IN UNCONFINED SPACES

UNCONFINED SPACE is space whose volume is not less

than 50 cubic feet per 1,000 Btu per hour (4.8 cubic meters

per kW) of the aggregate input rating of all appliances

installed in that space. Rooms communicating directly with

the space in which the appliances are installed, through

openings not furnished with doors, are considered a part

of the unconfi ned space.

In unconfi ned spaces in buildings, infi ltration may be

adequate to provide air for combustion, ventilation and

dilution of flue gases. However, in buildings of tight

construction (for example, weather stripping, heavily

insulated, caulked, vapor barrier, etc.), additional air may

need to be provided using the methods described in

“Appliances in Confi ned Space” that follows.”

APPLIANCES IN CONFINED SPACES

CONFINED SPACE is a space whose volume is less than

50 cubic feet per 1,000 Btu per hour (4.8cm per kW) of

the aggregate input rating of all appliances installed in

that space.

When drawing combustion air from inside a building to a

confi ned space, such a space should be provided with two

permanent openings. ONE WITHIN 12 in. (30cm) OF THE

ENCLOSURE TOP AND ONE WITHIN 12 in. (30cm) OF

THE ENCLOSURE BOTTOM. Each opening should have

a free area of 1 square inch per 1000 Btu/hr (22 cm

2

/kW)

of the total input of all appliances in the enclosure, but not

less than 100 square in. (645 cm

2

).

If the confi ned space is within a building, air for combustion

and ventilation must be obtained from outdoors. When

directly communicating with the outdoors or communicating

through vertical ducts, two permanent openings, located

in the above manner, should be provided. Each opening

should have a free area of not less than 1 square inch per

4000 Btu/hr (5.5 cm

2

/kW) of total input of all appliances in

the enclosure. If horizontal ducts are used, each opening

should have a free area of not less than 1 square inch per

2000 Btu/hr (11 cm

2

/kW) of the total input of all appliances

in the enclosure.

A. ALL AIR FROM INSIDE BUILDINGS: (See Figures 10

& 11)

The confi ned space should be provided with two permanent

openings communicating directly with an additional

room(s) of suffi cient volume so that the combined volume

of all spaces meets the criteria for an unconfi ned space.

The total input of all gas utilization equipment installed in

the combined space should be considered in making this

determination. Each opening should have a minimum free

area of 1 square inch per 1,000 Btu per hour (22 cm

2

/kW)

of the total input rating of all gas utilization equipment in

the confi ned space, but not less than 100 square in. (645

cm

2

). One opening should commence within 12 in. (30cm)

of the top and one commencing within 12 in. (30cm) of the

bottom of the enclosures.