Tuff Country 36100 - Dodge 09-11 Ram 1500 6 kit User Manual

Page 8

side.

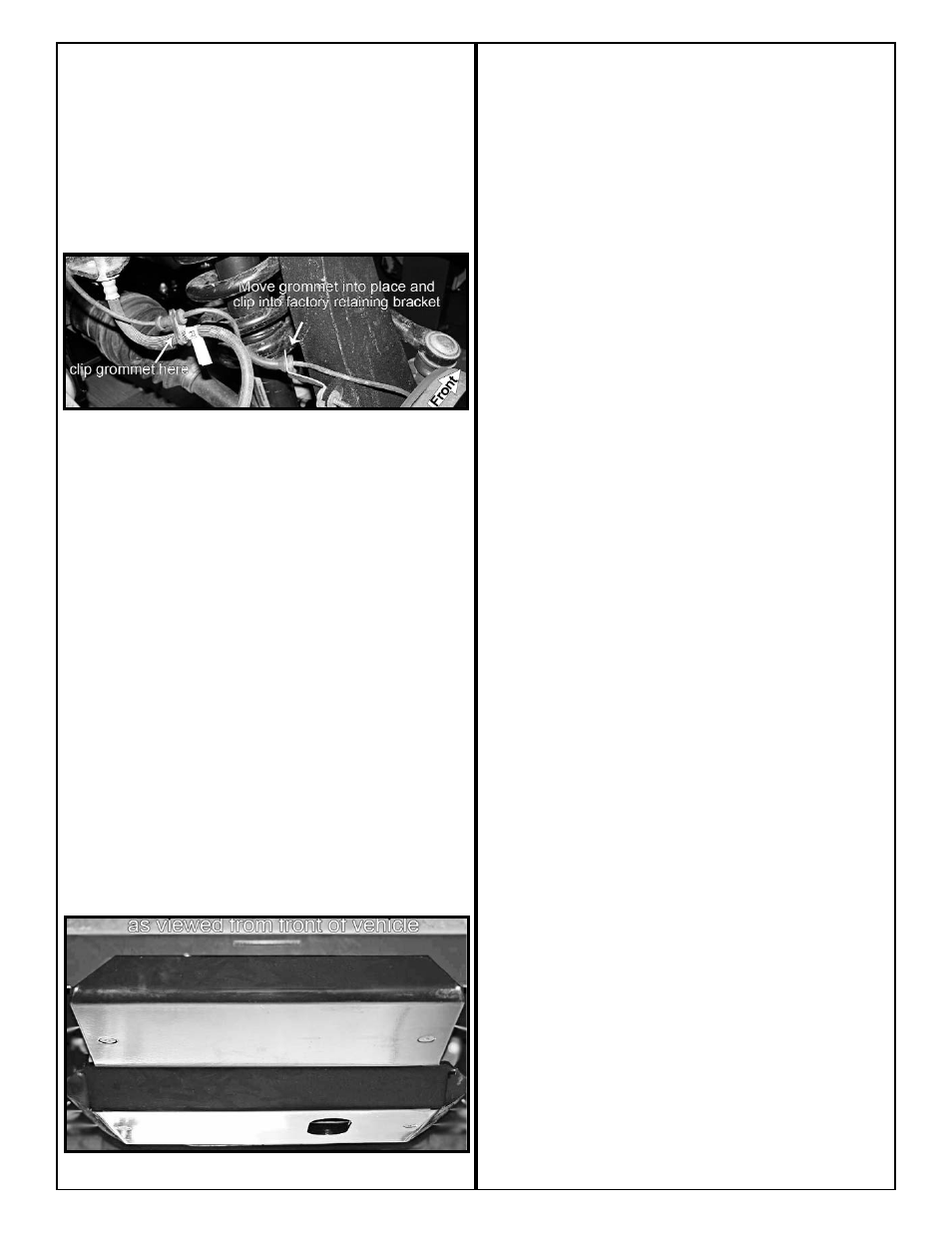

45. Working on the driver side, route the Wheel Speed

Sensor wire to the mounting bracket on the knuckle as

shown in the picture. The rubber grommet on the Wheel

Speed Sensor wire must be shifted. Apply some windex on

the Wheel Speed Sensor wire and rubber grommet so that

the Wheel Speed Sensor wire will slide easily through the

rubber grommet. When satisfied with the routing, insert the

Wheel Speed Sensor and rubber grommet into the mount-

ing bracket. Repeat procedure on the passenger side.

46. Working on the driver side, install the brake rotor and

caliper using the stock hardware. Make sure to use thread

locker or loctite and torque to 130 ft lbs. Repeat procedure

on the passenger side.

47. Working on the driver side, we are now going to

route/attach the Wheel Speed Sensor wire at the following

points in this order. At the rubber brake hose, at the rear leg

of the upper control am and then reconnect the Wheel

Speed Sensor wire at the quick disconnect point. Special

note: We will not be reattaching the connector to the inner

fender well. Repeat procedure on the passenger side.

48. Working on the driver side apply some anti-seize to the

factory anti-sway bar link threads. Install (3) 7/16” SAE

washers per side then install the anti-sway bar link bush-

ings and hardware. Attach anti-sway bar links to anti-sway

bar body. Tighten until the bushings start to mushroom.

Repeat procedure on the passenger side.

49. Locate the new skid plate. Also, locate the (6) new 3/8”

x 1” counter sunk bolts and (6) 3/8” flange lock nuts from

hardware bag 34100NB4. Install the new skid plate to the

front and rear cross members and secure using the new

3/8” x 1” bolts and hardware. Make sure to use thread lock-

er or loctite and torque to 30 ft lbs.

50. Working on the driver side add some thread locker or

loctite to the hardware attaching the front and rear cross

member to the frame mounts. Now torque this hardware to

75 ft. lbs. Repeat procedure on the passenger side.

51. Install the tires and wheel and carefully lower the vehi-

cle to the ground.

52. Move back to the lower control arm bolts and add some

thread locker or loctite and torque both the driver and pas-

senger side to 110 ft lbs.

53. Move back to the upper control arm bolts and add some

thread locker or loctite and torque both the driver and pas-

senger side to 130 ft lbs.

54. Move back to the lower strut bolt and add some thread

locker or loctite and torque both the driver and passenger

side to 155 ft lbs.

55. Block the rear tires of the vehicle so that the vehicle is

stable and can’t roll backwards. Safely lift the front of the

vehicle and support the frame with a pair of jack stands.

Place a jack stand on both the driver and the passenger

side. Now cycle the steering lock-to-lock and check then

double check to make sure that all components have prop-

er clearances. Pay close attention to brake hoses, wiring

and tire and wheel clearances. Lower vehicle to the

ground.

56. To begin installation, carefully block the front tires and

wheels so that the vehicle can not roll forward. Safely lift

the rear of the vehicle and support the vehicle with a pair of

jack stands. Place a jack stand on both the driver and the

passenger side. Next, remove the rear wheels and tires

from both sides.

57. Working on the driver the side, remove the stock shock

from the stock location. Save the stock hardware. New

longer rear shocks are needed after this suspension

system has been installed and the rear shocks need to

be ordered as a separate part #. If you have not already

ordered your rear shocks, please feel free to contact

Tuff Country or your local Tuff Country dealer and

order your rear shocks. Tuff Country recommends

installing a 30” fully extended nitrogen gas shock in

the rear. Repeat procedure on the passenger side.

58. Carefully lower down on both hydraulic floor jacks at the

same allowing just enough room for the rear coil springs to

be removed. Remove both the driver and passenger side

rear coils and discard.

59. Working on the driver side, loosen but do not remove

the stock upper and lower control arms at the axle mount

location. Repeat procedure on the passenger side.

60. Working on the driver side, remove the stock upper and

lower control arms from the frame mount location. Save the

stock hardware and let the control arms hang. Repeat pro-