Ariens 924 SNO-THRO 924109 User Manual

Page 13

4 - 13

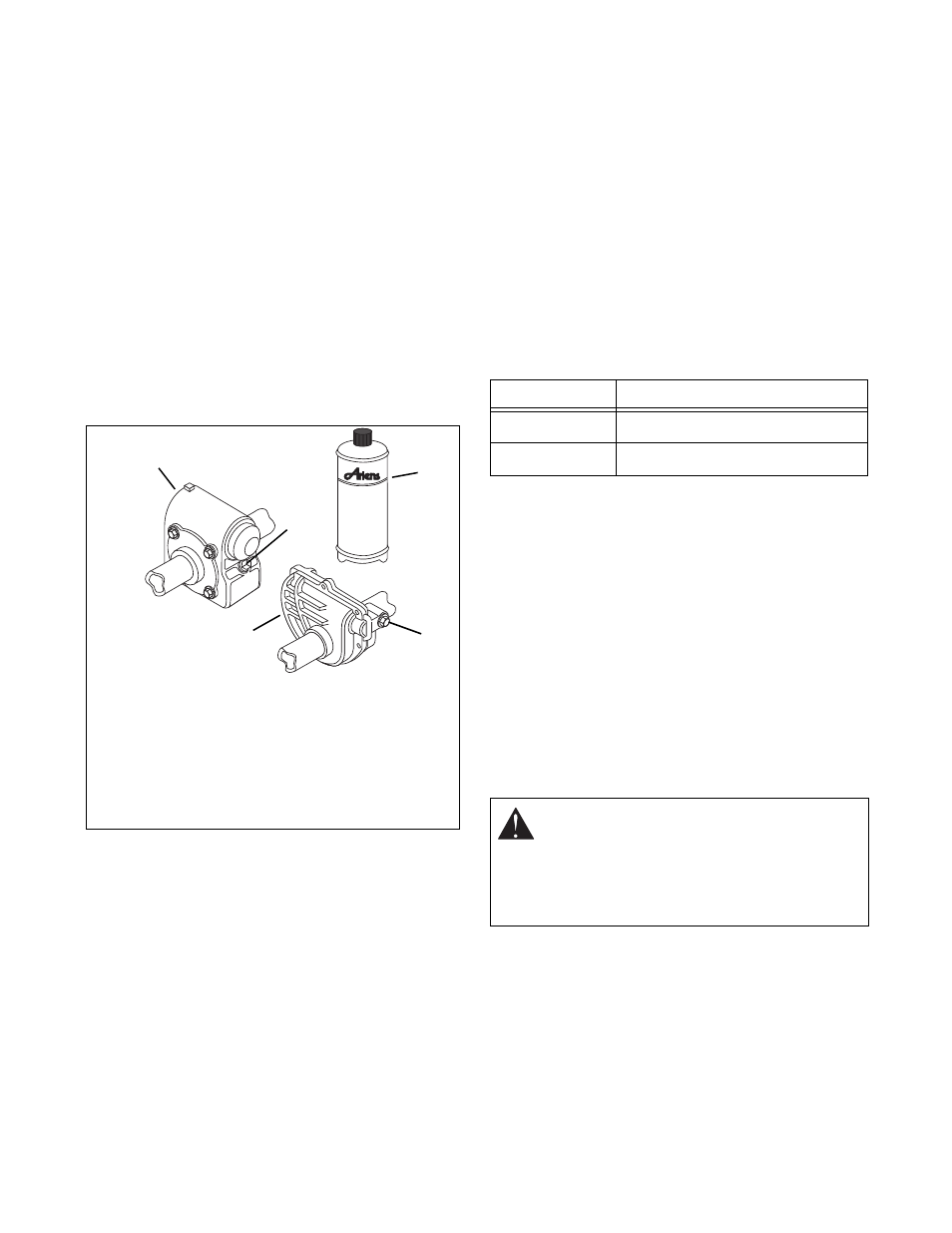

4.6 AUGER GEARCASE

IMPORTANT: Too much lubricant may cause excessive

leakage. Too little lubricant will cause gear and/or

bearing damage. Proper oil level must be maintained

for operation.

Gear cases are filled to the correct level at the factory.

Unless there is evidence of leakage, no additional

lubricant should be required. Check for evidence of

leakage every 25 hours or operation.

To ensure adequate lubricant level:

1. Remove filler plug. Lubricant must be at least up to

bottom of lubricant filler hole with unit resting on a

level-surface.

2. Add lubricant, if required, allow oil to drain to level

of plug and replace plug (Figure 4).

3. Use only Ariens special gear lubricant L-2

(P/N 00008000).

4.7 ENGINE

Cooling

The engine is air cooled. Air must circulate freely

around engine from Air Intake to cooling fins on

cylinder head and block, to prevent overheating.

Each year (more often if conditions require) remove

cooling shrouds and clean cooling fins. Clean external

surfaces of engine of dust, dirt, and oil deposits which

can contribute to improper cooling. See Engine

Manual.

IMPORTANT: DO NOT operate engine with cooling

shrouds removed. Engine overheating and damage will

result.

Engine Oil Check

The engine crankcase oil should be checked daily or

every 5 hours of operation. Oil level MUST be

maintained in safe operating range on dipstick at all

times or engine damage will result (See Engine

Manual).

To check, park unit on a flat, level surface and:

1. Clean all debris away from oil cap.

2. Remove oil cap and dipstick. Wipe oil of dipstick

with a clean cloth. Replace dipstick until cap

bottoms on tube. Remove dipstick again and

observe oil level. Oil should be at the Full (F) mark.

3. If low, add oil and bring up to the Full (F) mark.

IMPORTANT: DO NOT over fill. Oil level must not

exceed Full (F) mark.

4. Replace dipstick and cap. Clean up any spilled oil.

Engine Oil Change

Change oil after first 5 hours of operation, thereafter

change oil every 25 hours (more often if required).

NOTE: Run engine just prior to changing oil. Warm oil

will flow more freely and carry away more contamina-

tion.

1. Drain crankcase by removing oil drain plug (see

Engine Manual).

2. When oil has drained replace plug and refill engine

crankcase with new oil of proper grade.

3. Recheck oil level with dipstick.

4.8 TRACTION DRIVE BELT

NOTE: Unit should be in the Belt Service Position with

the attachment drive belt removed.

To Replace the Traction Drive Belt

1. Pull idler away from belt (Figure 5) and remove belt

from idler pulley, engine and drive pulley (it may be

necessary to turn engine pulley using rewind

starter).

2. Rotate belt fingers out and away from belt and

pulley by removing one cap screw and loosening

the other.

OS0620

Special

Gear

Lube-L2

Figure 4

1. Auger Gearcase-Cast Iron

2. Oil Fill and Drain Level Plug

3. Ariens Special L-2 Gear Lube

4. Auger Gearcase-Aluminum

1

2

3

4

2

Engine Oil Type

Ambient Temperature

SAE 5W30

Below 40

o

F (4

o

C)

SAE 30

Above 40

o

F (4

o

C)

WARNING: ROTATING PARTS can cut or

amputate body parts. Keep hands and feet

away.

Loose clothing, long hair or scarves can get

caught in rotating parts and cause death or

serious injury.