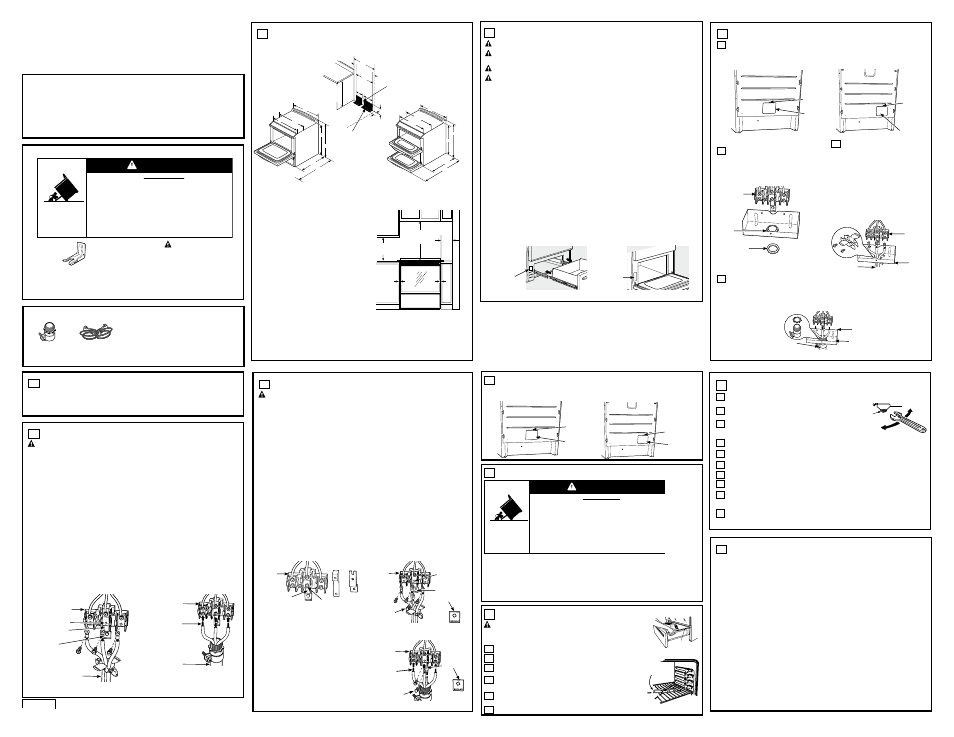

GE PHS920SFSS User Manual

Installation instructions slide-in electric ranges, Warning

36”

37

1

⁄

4

”

25

5

⁄

8

”

48”

29

7

⁄

8

”

29

7

⁄

8

”

31

1

⁄

4

”

29

7

⁄

8

”

25

5

⁄

8

”

36”

45”

29

7

⁄

8

”

31

1

⁄

4

”

37

1

⁄

4

”

8

ANTI-TIP DEVICE INSTALLATION

To reduce the

risk of tipping

the range, the

range must be

secured by a

properly installed

anti-tip bracket.

See installation

instructions

shipped with

the bracket

for complete

details before

attempting to

install.

To check if the bracket is installed and engaged properly, look underneath the range to see that the leveling

leg is engaged in the bracket. On some models, the storage drawer or kick panel can be removed for easier

inspection. If visual inspection is not possible, slide the range forward, confirm the anti-tip bracket is securely

attached to the floor or wall, and slide the range back so the leveling leg is under the anti-tip bracket. If the

range is pulled from the wall for any reason, always repeat this procedure to verify the range is properly

secured by the anti-tip bracket. Never completely remove the leveling legs or the range will not be secured to

the anti-tip device properly.

2

PREPARE THE OPENING (FOR INDOOR USE ONLY)

See illustrations for all rough-in and spacing dimensions. The range may be placed with 0”

clearance (flush) at the back wall and side walls of the cabinet.

BEFORE YOU BEGIN

Read these instructions completely and carefully.

•

IMPORTANT —

Save these instructions

for local inspector’s use.

•

IMPORTANT —

Observe all

governing codes and ordinances.

• Note to Installer – Be sure to leave these

instructions with consumer.

• Note to consumer – Keep these

instructions for future reference.

• Skill level – Installation of this appliance

requires a qualified installer or electrician.

• Proper installation is the responsibility of the

installer.

• Product failure due to improper installation is

not covered under warranty.

FOR YOUR SAFETY:

Installation Instructions

Slide-In Electric Ranges

MATERIALS YOU MAY NEED

TOOLS YOU WILL NEED

Anti-Tip Bracket

Kit Included

(UL Listed 40 AMP)

4-Wire Cord 4’ long OR

3-Wire Cord 4’ long

Squeeze Connector

(For Conduit

Installations Only)

1

REMOVE PACKAGING MATERIALS:

Failure to remove packaging materials

could result in damage to the appliance. Remove all packing parts from oven, racks, heating

elements and drawer. Also, remove protective film and labels on the outer door, cooktop and

control panel.

Drill with 1/8” Bit

Safety Glasses

Adjustable Wrench

Level

Tin Snips

Tape Measure

Pliers

1/4” Nut Driver

5/16” Nut Driver

Questions?

Call 1.800.GE.CARES (1.800.432.2737) or visit www.GEAppliances.com

In Canada, call 1.800.561.3344 or visit www.GEAppliances.ca

WARNING —

Before

beginning the installation, switch

power off at service panel and lock

the service disconnecting means to

prevent power from being switched

on accidentally. When the service

disconnecting means cannot be

locked, securely fasten a prominent

warning device, such as a tag, to the

service panel.

2

1

⁄

2

”

14

1

⁄

2

”

2

1

⁄

2

”

7”

7

1

⁄

2

”

25”

SINGLE OVEN

DOUBLE OVEN

A

NOTE C

B

A

C

Both

Sides

NOTE: Use a 4’ power cord to prevent interference with

the storage drawer. Power cords 4

1

⁄

2

’ to 6’ long may

have to be dressed to allow for proper drawer closing.

MINIMUM DIMENSIONS BETWEEN COOKTOP,

WALLS AND ABOVE THE COOKTOP:

A. Make sure the wall covering, countertop, flooring

and cabinets around the range can withstand the

heat (up to 200°F) generated by the range.

B. Allow 30” minimum clearance between surface

units and bottom of unprotected wood or metal

cabinet, or allow a 24” minimum when bottom

of wood or metal cabinet is protected by no less

than 1/4” thick flame retardant millboard covered

with not less than No 28 MSG sheet metal, (.015”),

.015” thick stainless steel, .024”

aluminum or .020” copper.

Acceptable electrical

outlet area. Orient

electrical receptacle so

the length is parallel to

floor.

Use a flush mount outlet

for double oven models.

C. This appliance has been approved for 0” spacing to adjacent surfaces above the cooktop. However, a

6” minimum spacing to surfaces less than 15” above the cooktop and adjacent

cabinet is recommended to reduce exposure to steam, grease splatter and heat.

To reduce the risk of burns or fire when reaching over hot surface elements, cabinet storage space

above the cooktop should be avoided. If cabinet storage space is to be provided above

the cooktop, the risk can be reduced by installing a range hood that projects at least 5” beyond

the front of the cabinets. Cabinets installed above the cooktop must be no deeper than 13”.

Rating plate

SINGLE OVEN

Rating plate

DOUBLE OVEN

4

POWER CORD AND CONDUIT INSTALLATION

A

Remove wire cover (on the back of range) by removing screws using a 1/4” nut driver. You can

access the terminal block by either removing a terminal block cover (on some models) or the

wire cover. Do not discard these screws.

B

For power cord and 1” conduit only, remove the

knockout ring (1

3

⁄

8

”) located on bracket directly

below the terminal block. To remove the

knockout, use a pair of pliers to bend the

knockout ring away from the bracket and

twist until ring is removed.

D

For 3/4” conduit installations only, purchase a squeeze connector matching the diameter of your

conduit and assemble it in the hole. Insert the conduit through the squeeze connector and tighten.

Allow enough slack to easily attach the wires to the terminal block. NOTE: Do not install the conduit

without a squeeze connector. The squeeze connector MUST be installed before reinstalling the rear

range wiring cover.

Terminal block cover

Screw to

remove

terminal

block cover

Back of range

Knockout

ring in

bracket

Knockout ring

removed

Terminal block

(appearance

may vary)

C

For power cord installations only (see the

next step if using conduit), assemble the

strain relief in the hole. Insert the power

cord through the strain relief and tighten.

Allow enough slack to easily attach the

cord terminals to the terminal block. If tabs

are present at the end of the winged strain

relief, they can be removed for better fit.

NOTE: Do not install the power cord without

a strain relief. The strain relief bracket MUST

be installed before reinstalling the rear range

wiring cover.

Power cord

Strain relief

Terminal

block

Bracket

Squeeze

connector

Terminal block

Conduit

Bracket

PROCEED TO STEP 5 OR 6.

Wire tips

Terminal

block

Conduit

5

3-WIRE INSTALLATION

WARNING:

The neutral or ground wire of the power cord must be connected to the neutral

terminal located in the center of the terminal block and the ground strap must connect the neutral terminal

to the ground plate. The power leads must be connected to the lower left and the lower right terminals of the

terminal block.

DO NOT remove the ground strap connection.

FOR POWER CORD INSTALLATION

A. Remove the 3 lower terminal screws from the terminal block.

B. Insert the 3 terminal screws through each power cord terminal ring and into the lower terminals of

the terminal block. Be certain that the center wire (white/neutral) is connected to the center lower

position of the terminal block.

C. Tighten screws securely into the terminal block.

FOR CONDUIT INSTALLATION

A. Loosen the 3 lower terminal screws on the terminal block. Strip wire to exposed tip about 5/8” long.

B. Insert the center (white/neutral) wire tip through the bottom center terminal block opening. On certain

models, the wire will need to be inserted through the ground strap opening and then into the bottom

center block opening. Insert the two side bare wire tips into the lower left and the lower right terminal

block openings.

C. Tighten the screws until the wire is firmly secured (35 to 50 inch-lbs.). Do not over-tighten the screws.

NOTE: ALUMINUM WIRING: Aluminum building wire may be used but it must be rated for the correct

amperage and voltage.

PROCEED TO STEP 7.

Ground strap

Terminal block

(appearance

may vary)

Neutral terminal

Power cord

Ground

plate

Power Cord

Conduit

31-10769

06-11 GE

6

4-WIRE INSTALLATION

WARNING:

The neutral wire of the supply circuit must be connected to the neutral terminal

located in the lower center of the terminal block. The power leads must be connected to the lower left and the

lower right terminals of the terminal block. The grounding lead must be connected to the frame of the range with

the ground plate and the green ground screw.

FOR POWER CORD INSTALLATION

A. Remove the 3 lower terminal screws from the terminal block. Remove the ground screw and ground

plate and retain them. Cut and discard the ground strap. DONOTDISCARDANYSCREWS.

B. Insert the one ground screw into the power cord ground wire terminal ring, through the ground plate

and into the frame of the range.

C. Insert the 3 terminal screws (removed earlier) through each power cord terminal ring and into the lower

terminals of the terminal block. Be certain that the center wire (white/neutral) is connected to the center lower

position of the terminal block. Tighten screws securely into the terminal block.

FOR CONDUIT INSTALLATION

A. Loosen the 3 lower terminal screws on the terminal block. Remove the ground screw and ground plate and

retain them. Cut and discard the ground strap. DO NOT DISCARD ANY SCREWS. Strip wire to exposed tip

about 5/8” long.

B. Insert the ground bare wire tip between the range frame and the ground plate (removed earlier)

and secure it in place with the ground screw (removed earlier). Insert the bare wire (white/neutral) tip through

the bottom center of the terminal block opening. Insert the two side bare wire tips into the lower left and the

lower right terminal block openings.

C. Tighten the screws until the wire is firmly secured (35 to 50 inch-lbs.). Do not over-tighten the screws.

NOTE: ALUMINUM WIRING: Aluminum building wire may be used but it must be rated

for the correct amperage and voltage.

Before–Power Cord and Conduit

Terminal

block

Terminal

block

Neutral

terminal

Neutral

terminal

Ground

strap

Ground plate

(grounding to

range)

Ground

screw

Ground strap

or

After–Conduit

Terminal

block

Ground

plate

(grounding

to range)

Wire

tips

Ground screw

After–Power Cord

7

REPLACE THE WIRE COVER

Replace wire cover on range back by sliding its left edge under the retaining tabs and replace the

screws removed earlier. Make sure that no wires are pinched between cover and range back.

Terminal

block cover

Screw to

remove

terminal

block cover

Back of range

Stop

9

LEVEL THE RANGE

WARNING:

Never completely remove the leveling leg

as the range will not be secured to the anti-tip device properly.

MODELS WITH STORAGE DRAWER OR KICK PANELS

A

Plug in unit and slide into place. Pull drawer out until it stops.

B

Lift front of drawer until the stops clear the guide. Remove the drawer.

C

Install the oven shelves in the oven and position the range where

it will be installed.

D

Check for levelness by placing a spirit level on one of the oven shelves.

Take two readings—with the level placed diagonally first

in one direction and then the other.

E

The front leveling legs can be adjusted from the bottom

and the rear legs can be adjusted from the top or the bottom.

F

Use an adjustable wrench to adjust the leveling legs until the range is level.

Leg

leveler

Raise

range

10

FINAL INSTALLATION CHECKLIST

• Check to make sure the circuit breaker is closed (RESET) or the circuit fuses are replaced.

• Be sure power is in service to the building.

• Check that all packing materials and tape have been removed. This will include tape on metal panel under

control knobs (if applicable), adhesive tape, wire ties, cardboard and protective plastic. Failure to remove

these materials could result in damage to the appliance once the appliance has been turned on and

surfaces have heated.

• Check that the door and drawer are parallel to each other and that both operate smoothly. If they

do not, see the Owner’s Manual for proper replacement.

• Check to make sure that the rear leveling leg is fully inserted into the Anti-Tip bracket and that the bracket

is securely installed.

OPERATION CHECKLIST

• Turn on one of the surface units to observe that the element glows within 60 seconds. Turn the unit

off when glow is detected. If the glow is not detected within the time limit, recheck the range wiring

connections. If change is required, retest again. If no change is required, have building wiring checked for

proper connections and voltage.

• Check that the Clock (on models so equipped) display is energized. If a series of horizontal red

lines appear in the display, disconnect power immediately. Recheck the range wiring connections.

If change is made to connections, retest again. If no change is required, have building wiring checked for

proper connections and voltage. It is recommended that the clock be changed if the red lines appear.

• Be sure all range controls are in the OFF position before leaving the range.

3”

30”

Spirit level

ELECTRICAL REQUIREMENTS

WARNING:

This appliance must be properly grounded.

WARNING:

All new constructions, mobile homes, recreational vehicles and installations where

local codes do not allow grounding through neutral, require a 4-conductor UL-listed range cord.

WARNING:

To prevent fire or shock, do not use an extension cord with this appliance.

WARNING:

To prevent shock, remove house fuse or open circuit breaker before beginning

installation.

We recommend you have the electrical wiring and hookup of your range connected by a qualified

electrician. After installation, have the electrician show you how to disconnect power from the range.

You must use a single-phase, 120/208 VAC or 120/240 VAC, 60 hertz electrical system. If you connect to

aluminum wiring, properly installed connectors approved for use with aluminum wiring must be used.

Effective January 1, 1996, the National Electrical Code requires that new construction (not existing) utilize

a 4-conductor connection to an electric range. When installing an electric range in new construction,

mobile home, recreational vehicle, or an area where local codes prohibit grounding through the neutral

conductor, refer to the section on four-conductor branch circuit connections.

Check with your local utilities for electrical codes which apply in your area. Failure to wire your oven

according to governing codes could result in a hazardous condition. If there are no local codes, your

oven must be wired and fused to meet the National Electrical Code, NFPA No. 70 – latest edition,

available from the National Fire Protection Association.

This appliance must be supplied with the proper voltage and frequency, and connected to an individual,

properly grounded, 40 amp (minimum) branch circuit protected by a circuit breaker or time-delay fuse.

Use only a 3-conductor or a 4-conductor UL-listed range cord. These cords may be provided with ring

terminals on wire and a strain relief device.

A range cord rated at 40 amps with 125/250 minimum volt range is required. A 50 amp range cord is not

recommended but if used, it should be marked for use with nominal 13⁄8” diameter connection openings.

Care should be taken to center the cable and strain relief within the knockout hole to keep the edge from

damaging the cable.

The rating plate is located on the oven frame or on the side of the drawer frame.

3

Screw to

remove

terminal

block cover

Back of range

Terminal

block cover

Screw to

remove

terminal

block cover

Unit will not mount flush

to counter when heights

are less than 36”.

On models with baking

or warming drawers,

electrical outlet must not

be in this area.

9

LEVEL THE RANGE (CONT.)

G

Position cord so that it does not interfere with drawer.

Place drawer rail on guides. Push the drawer in until it stops.

H

Lift front of drawer and push in until the stops clear

the guides.

I

Lower the front of the drawer and push in until it closes.

MODELS WITH BAKING, WARMING DRAWERS OR DOUBLE OVEN

A

Plug in the unit.

B

Measure the height of your countertop at the rear of the opening.

C

Adjust two rear leveling legs so that the rear of cooktop is at the same height as the counter.

D

Slide unit into place.

E

Install oven shelves in the oven and position the range where it will be installed.

F

Check for levelness by placing a spirit level on one of the oven shelves.

Take two readings—with the level placed diagonally first in one direction

and then the other.

G

Adjust front leveling legs until the range is level.

If you did not receive an anti-tip bracket with your purchase,

call 1.800.626.8774 to receive one at no cost. (In Canada,

call 1.800.561.3344.) For installation instructions of the bracket,

visit: www.GEAppliances.com. (In Canada, www.GEAppliances.ca.)

Terminal

block cover

Back of range

A child or adult can tip the range and be killed.

Verify the anti-tip bracket has been properly installed

and engaged.

Ensure the anti-tip bracket is re-engaged when the range

is moved.

Do not operate the range without the anti-tip bracket in

place and engaged.

Failure to follow these instructions can result in death or

serious burns to children or adults.

Tip-Over Hazard

WARNING

A child or adult can tip the range and be killed.

Verify the anti-tip bracket has been properly installed

and engaged.

Ensure the anti-tip bracket is re-engaged when the range

is moved.

Do not operate the range without the anti-tip bracket in

place and engaged.

Failure to follow these instructions can result in death or

serious burns to children or adults.

Tip-Over Hazard

WARNING