Warning – Alliance Laundry Systems Clothes Dryer User Manual

Page 10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

510963

10

4. Tighten all connections securely. Turn on gas and

check all pipe connections (internal & external)

for gas leaks with a non-corrosive leak detection

fluid.

NOTE: The dryer and its appliance main gas valve

must be disconnected from the gas supply piping

system during any pressure testing of that system

at test pressures in excess of 1/2 psi (3.45 kPa).

Refer to Step 9 (Check Heat Source).

L.P. (Liquefied Petroleum) Gas, 2500 Btu/ft

3

(93.1 MJ/m

3

) service must be supplied at 10 ± 1.5 inch

water column pressure.

For proper operation at altitudes above 3000 feet (915 m)

the L.P. gas valve spud orifice size must be reduced to

ensure complete combustion. Refer to Table 3.

NOTE: DO NOT connect the dryer to L.P. Gas

Service without converting the gas valve. Install

L.P. Gas Conversion Kit 649P3, available at extra

cost.

Step 4: (Electric Dryer Only) Connect

Electrical Plug

Dryer requires 120/240 Volt or 120/208 Volt, 60 Hertz,

3 wire electrical suppy. Refer to serial plate for

specific electrical requirements.

IMPORTANT: Use only a new U.L. listed No. 10

(copper wire only) three conductor power supply

cord kit rated 240 Volts (minimum) 30 Amperes

and labeled as suitable for use in a clothes dryer.

NOTE: The wiring diagram is located inside the

control hood.

Grounding Information

• This dryer must be connected to a grounded

metal, permanent wiring system; or an

equipment-grounding conductor must be run

with the circuit conductors and connected to the

equipment-grounding terminal or lead on the

dryer.

• The dryer has its own terminal block that must be

connected to a separate branch, 60 Hertz, single

phase circuit, AC (alternating current) circuit,

fused at 30 Amperes (the circuit must be fused

on both sides of the line). Electrical service for

the dryer should be of maximum rated voltage

(208 or 240 Volt, depending on heating

element) listed on the nameplate. Do not

connect dryer to 110, 115, or 120 Volt circuit.

• Heating elements are available for field

installation in dryers which are to be connected to

electrical service of different voltage than that

listed on nameplate, such as 208 Volt.

NOTE: Branch circuit wire size requirements to

laundry room outlet are shown in Table 4.

• The power cord connection between wall

receptacle and dryer terminal block IS NOT

supplied with dryer. Type of power cord and

gauge of wire must conform to local codes.

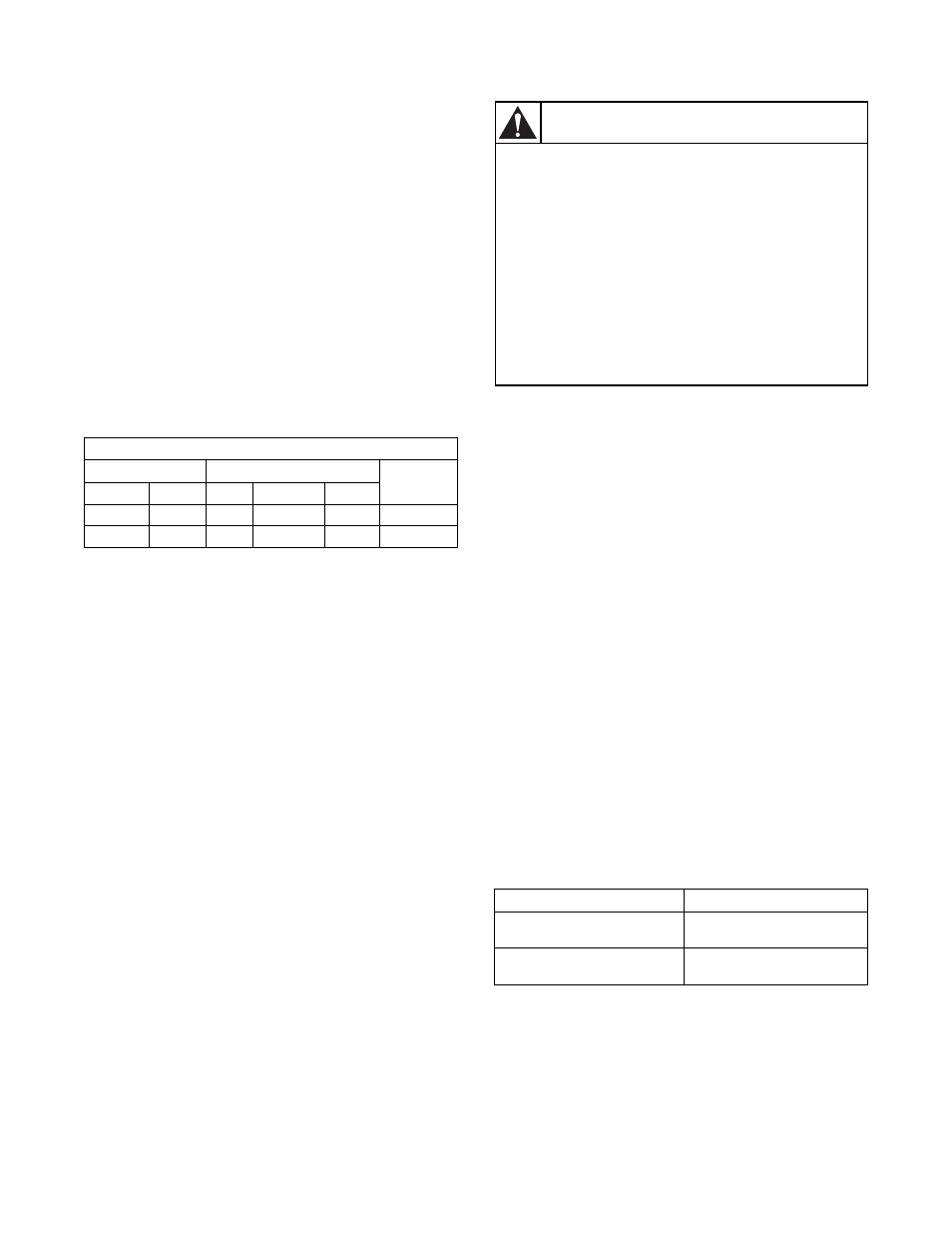

L.P. Altitude Adjustments

Altitude

Orifice Size

Part No.

feet

m

No.

inches

mm

3000

915

55

0.0520

1.32

58755

8000

2440

56

0.0465

1.18

503786

Table 3

Wire Length

Dryer

Less than

4.5 m (15 ft.)

Listed No. 10 AWG

Copper wire only

Longer than

4.5 m (15 ft.)

Listed No. 8 AWG

Copper wire only

Table 4

To reduce the risk of fire, electric shock,

serious injury or death, all wiring and

grounding MUST conform with the latest

edition of the National Electrical Code,

ANSI/NFPA 70, or the Canadian Electrical

Code, CSA C22.1, and such local

regulations as might apply. It is the

customer’s responsibility to have the wiring

and fuses installed by a qualified electrician

to make sure adequate electrical power is

available to the dryer.

W521

WARNING