Manual tuning – Athena Technologies 16C User Manual

Page 32

28

Manual Tuning

Manual Tuning Procedure

(Zeigler-Nichols PID Method)

This tuning method may be used for non-temperature control

processes or if the spread between ambient temperature and

process operating temperature is small. For best results, the

use of a recording device is required when tuning with this

method.

1) For temperature control processes, disable any cooling

device used.

2) With the power off and the controller NOT in the Key

Lockout security level, apply power and immediately put

the controller in Standby mode by pressing the Mode/

Enter

key for three seconds, the Raise

key until

appears and press the Mode/Enter key again.

3) If you have a direct-acting output, it must be disabled

before proceeding further

=

.

4) Under the Control menu, make sure that the derivative

term

, the offset term

, and the integral

term

are all set to zero, and the proportional

band

or

is set to the maximum setting.

5) Adjust setpoint to the desired value with the Raise/Lower

keys.

6) Press the Mode/Enter

key for four seconds, the Raise

key twice

, and the Mode/Enter key again to

return the controller to normal operation.

While some processes

other than heat or

cool applications may

respond successfully to

autotuning procedures,

the controller may need

to be manually tuned

for non-temperature

processes.

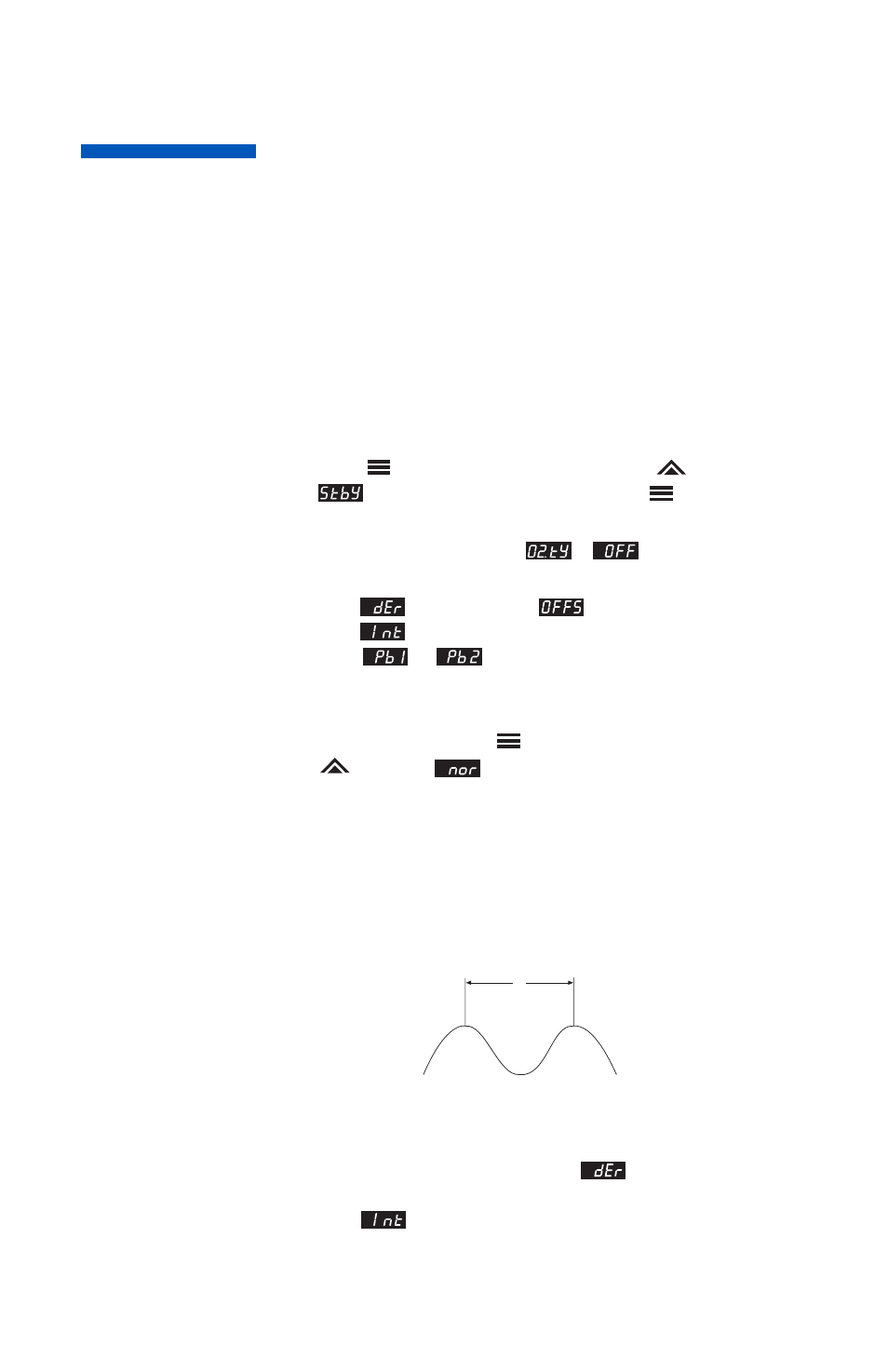

7) While monitoring the recording device, decrease the

proportional band value by repeatedly halving the

value until a small, sustained temperature oscillation is

observed. Measure the period of one cycle of oscillation

(“T” on the diagram below).

8) Divide the period of oscillation (T) by eight. The resulting

number is the correct Derivative

time in seconds.

Multiply this number by four. This is the correct Integral

time

in seconds.

9) Multiply the bandwidth value obtained in Step 7 by 1.66

and enter this as the new proportional band value.

T