Timeguard TGVL05 User Manual

Weathersafe vision

Weathersafe Vision

Installation and Operating

Instructions

IP66 Products covered by

these instructions

TGVL01

One gang two way switch 10AX

TGVL02

Two gang two way switch 10AX

TGVL03

One gang bell push

TGVL05

One gang double pole switch 20A

TGV101

One gang socket switched 13A

TGV201

Two gang socket switched 13A

TGV104

One gang RCD spur

TGV204

Two gang RCD protected socket

13A

(passive/latching)

TGV205

Two gang RCD protected socket

13A

(active/non-latching)

TGV203

Combined timer and socket

TGV103

One gang switched fused spur 13A

General

Please note that all instructions are to be left with the

customer after installation.

The Weathersafe Vision range is manufactured from

tough, durable thermoplastic, and is intended for use in

an outdoor environment, or one in which the protection

provided by the Weathersafe Vision range is required.

All the products are rated IP66, for protection against

water and dust. All Weathersafe Vision products need to

be fi tted with waterproof cable and conduit entries to

maintain their IP rating once installed.

The weather plus range complies with the following

standards.

• IP66 rating: BS EN 60529

• Socket outlets: BS 1363

• RCD units: BS 7288

• Fused connection units: BS 1363

• Switches: BS EN 60669

• All products in the range comply with the low

voltage directive LV 72/23/EEC and where

relevant the EMC directive 89/336/EEC

Voltage: 230V AC 50Hz

Operating temperature range: -5° to 55°C

Installation instructions

• These products should be installed by a competent

person (e.g. qualifi ed electrician) in accordance with

these instructions and in compliance with the

appropriate clauses of the current edition if the IEE

wiring and building regulations. Sockets should be

connected via a suitable RCD device.

• Disconnect the mains electricity supply

before

installing.

• The Weathersafe Vision range is designed to be

mounted on a vertical fl at surface, with socket outlets

not more than 1 metre above the ground.

• The rear box shall be mounted on the wall using no.8

wood screws and wall plugs if necessary (see fi g. 1).

• If the mounting surface is uneven use a sheet of

marine ply as a base plate then fi t the rear box to it.

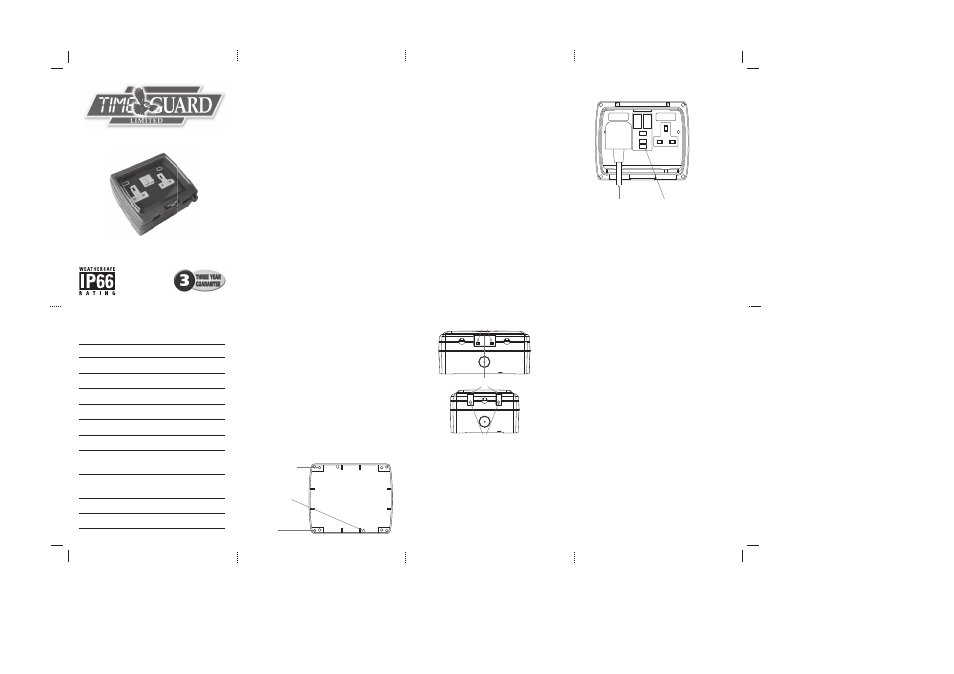

Fig. 1

Rear Box (double)

If conduit is to be used then please follow the

instructions below:

• The drain feature must be drilled out using

a 5mm drill if top or side entry conduit is used.

Opening this drain hole will reduce the IP rating

of the product. Remember – open out the lower

drain feature only and only if required by

conduit entry being used.

• If bottom entry conduit is used, there must be

adequate drainage from the lowest point of

the

conduit.

• The relevant cable entry knockout should

be carefully removed by scoring the groove

around the knockout with a sharp knife and

then tapping it out with a small hammer.

A waterproof cable or conduit entry must

then be fi tted in its place.

• If two cable entry positions are used with

metal conduit, then earth continuity between

the conduits must be maintained.

• Ensure that the gasket is correctly fi tted,

and tighten the four screws (supplied) to fi x

the front cover in place (see fi g. 1). Do not

overtighten. Use of an electric screwdriver

is not recommended.

Operating Instructions

Fig. 2

Single and double boxes – side view of bottom.

• The lid may be opened by pressing in the tab(s)

on the front to release the snaps and then lifting

the lid (see fi g.2).

• Plugs may be inserted into the sockets and the

socket switches turned on.

• The lid should then be closed to maintain the

IP rating taking care to ensure that the cables

are aligned with the centre of the cable seals

(see

fi g. 3). Finally engage the snaps (see fi g. 2)

by pulling out the tab(s) while maintaining

pressure to close the lid.

Fig. 3

Rear Box (double with 2 gang RCD sockets)

Cleaning

• Care should be taken when cleaning

this

product.

• Inside the lid should only be wiped with a

clean dry cloth.

• The outside can be cleaned with

mild

detergent.

• Solvent based cleaners should not be used.

• Advice should be sought before installing this

product in an environment where it is likely to

be subjected to chemicals, oils or solvents.

Weathersafe Vision Products with RCD’s

(TGV104, TGV204, TGV205)

Always test the RCD before use.

To test: Ensure supply is connected

RESET – press the grey (blue for TGV205) button

marked Reset (R), the status indicator should show red.

TEST – press the red button marked Test (T),

status indicator should show black. This indicates

that the RCD has been tripped and power has been

disconnected from the outlet.

RESET – press the grey (blue for TGV205) button

marked Reset (R) again, the status indicator

should show red.

If all the above operations work satisfactorily, the RCD

is safe for use.

If the procedure is not completed satisfactorily do not

use the RCD and seek professional advice.

In applications such as hand driers it may not be

practical to expect each user to test before use. In this

case we suggest an appropriate person applies the test

routine twice a day.

4 x fi xing holes for

no. 8 woodscrews

Drain feature,

use only lower if

required

Front cover

fi xing holes

Cable aligned with

centre of seals

Status indicator

T

R

Push here and lift up

Snaps

Snaps

Fold

Fold

Fold

Fold

Fold