Pumps: ½ hp – 3 hp, Tools needed, Operation & installation – Sterlco 4300 Series Stainless Steel Condensate Pumps User Manual

Page 6

Page 6 of 10

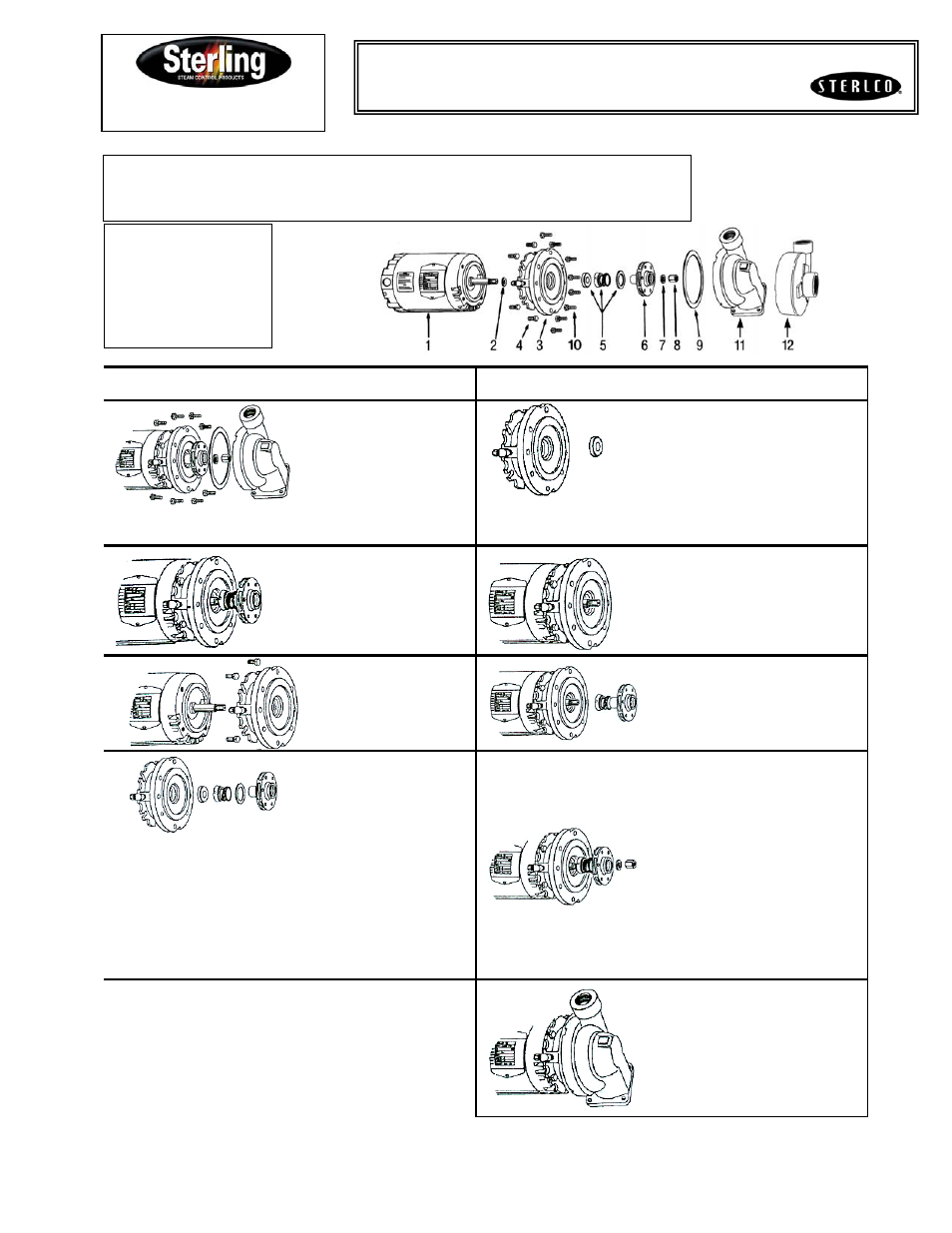

Replacing the Rotary Seal Assembly

On J Series Sterlco

®

Pumps: ½ HP – 3 HP

1. Motor

5. Rotary Seal Assembly

9. Housing Gasket

2. Water Slinger

6. Impeller

10. Pump Screws (8)

3. Bracket

7. Lock Washer

11. Vertical Inlet Casting

4. Motor Screws (4)

8. Impeller Nut

12. Horizontal Inlet Casting

REMOVAL OF OLD SEAL ASSEMBLY

INSTALLATION OF NEW SEAL ASSEMBLY

A) Remove 8 pump screws

and lift out pump and motor;

remove drip cover. Insert

large screwdriver into slot at

end of motor shaft; hold

shaft steady and remove

impeller nut and washer

from nose of impeller by

turning counterclockwise.

E) Coat outside edge of new seat

with seal lubricant and slip it into the

bracket. Press into bracket with

thumbs or wooden dowel. Handle

seat carefully so sweating surfaces

are not scratched or chipped…be

sure it is squarely seated.

B) While still holding motor

shaft steady with

screwdriver, use 1"”socket

to remove impeller by

turning counterclockwise.

F) Remount bracket on motor.

C) Remove the 4 motor

screws and separate the

bracket from the motor.

G) Lubricate impeller hub with seal

lubricant, Slip new bellows and

spring onto impeller hub. Be sure

bellows slide freely on impeller hub.

D) Remove old seal parts from impeller hub and bracket. Be

sure water slinger is in place. Clean the recess in the bracket so

that the new seat will fit perfectly and make a watertight joint. If

bracket is badly eroded at recess, through severe use, casting

should be replaced. Clean all gasket surfaces. Clean impeller

hub thoroughly; remove loose particles of dirt, etc. Check prime

tube or seal flush line and clean as required.

H) Thread impeller on motor shaft

extension and secure with washer

and impeller nut. Hold shaft with

screwdriver slot while tightening.

I) Replace motor assembly onto

volute; using new housing gasket.

Secure with pump screws. Be

certain gasket is seated properly.

Operation & Installation

Tools Needed:

Large Screwdriver

7/16” Wrench

9/16” Wrench

5/8” Socket

1” Socket