Dwyer BTK2 User Manual

Page 2

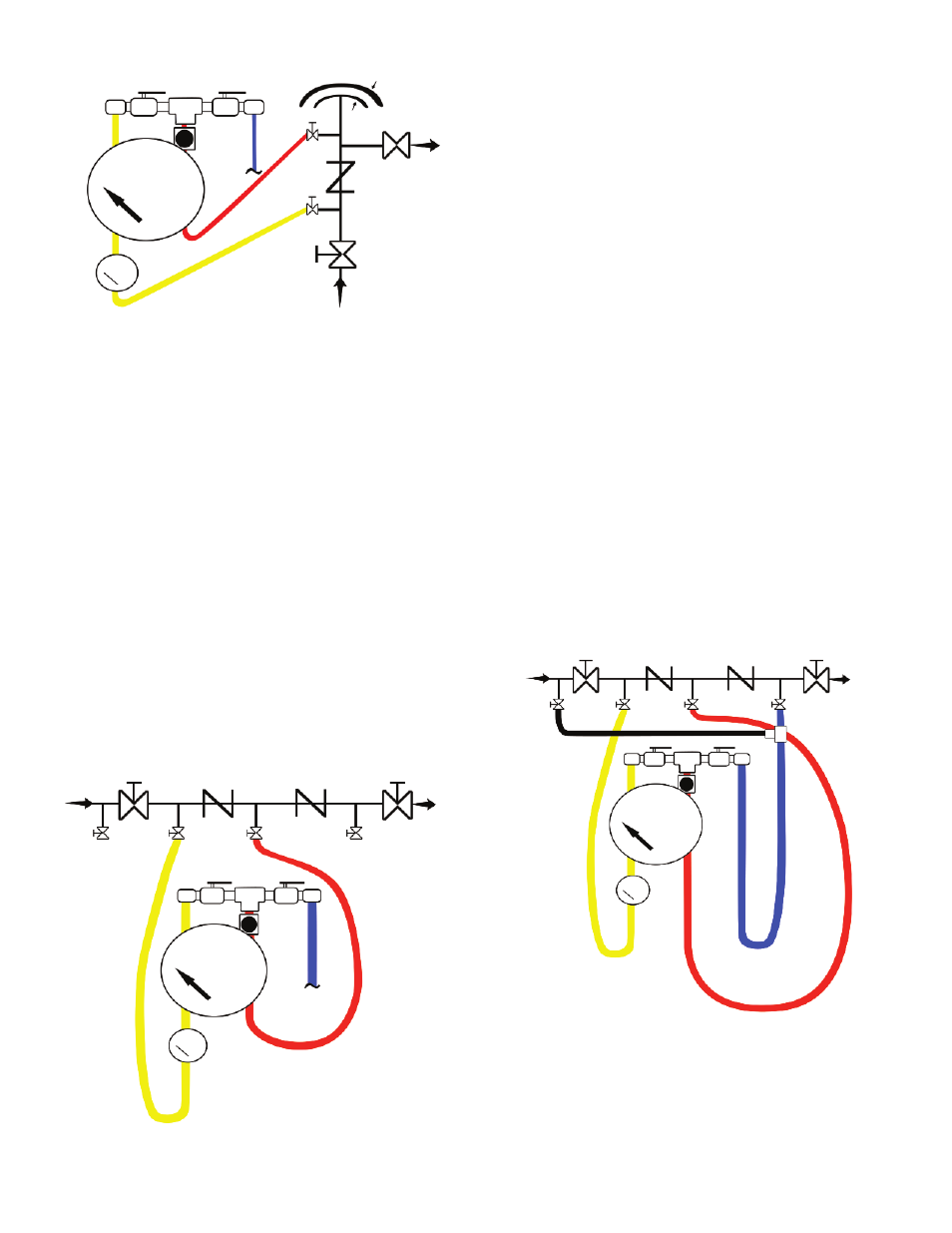

Reduced Pressure Principle Backflow Preventer

Field testing of a reduced pressure principle backflow preventer is accomplished

utilizing a differential pressure gage such as the BTK2 test kit. The device is tested

for three optional characteristics: i.e., (1) the first check valve is tight and maintains a

minimum of 5 psi differential pressure, (2) the second check valve is tight against

backpressure and (3) the relief valve opens at a minimum of 2 psi below inlet supply

pressure. Testing is performed as follows:

Step 1 - Refer to Figure 2

Test to ensure that the first check valve is tight and maintains a minimum pressure of

5 psi differential pressure using the following procedure. Perform with Ball Valve C

closed.

1. Verify that number 1 shut-off valve is open. Close number 2 shut-off valve. If there

is no drainage from the relief valve, it is assumed that the first check valve is tight.

2. Close all test kit valves.

3. Connect the high pressure hose (yellow) to test cock number 2.

4. Connect the low pressure hose (red) to test cock number 3.

5. Open test cocks number 2 and number 3.

6. Open high pressure side needle valve B on test kit bleeding the air from the high

pressure hose. Close the high pressure side ball valve A.

7. Open the low pressure side needle valve B on test kit bleeding air from the low

pressure hose (red). Close the low side needle valve B. Record the differential gage

pressure reading. It should be a minimum of 5 psid.

Step 2- Refer to Figure 3

Test to ensure that the second check valve is tight against backpressure using the

following procedure.

1. Leaving the hoses hooked up as in the conclusion of Step 1, connect vent hose

(blue) to test cock number 4.

2. Open test cock number 4, the high pressure ball valve A and the bypass hose ball

valve C on the test kit. (This supplies high pressure water downstream of check valve

number 2.) If the differential pressure gage reading drops and water comes out of the

relief valve, the second check valve is recorded as leaking. If the differential pressure

gage reading remains steady, and no water comes out of the relief valve, the second

check valve is considered tight.

3. To check the tightness of number 2 shut-off valve, leave the hoses hooked up the

same as at the conclusion of Step 2 (2), and then close test cock number 2. This stops

the supply of any high pressure water downstream of check valve number 2. If the

differential pressure gage reading holds steady, the number 2 shut-off valve is

recorded as being tight. If the differential pressure gage reading drops to zero, the

number 2 shut-off valve is recorded as leaking.

With a leaking number 2 shut-off valve, the device is, in most cases, in a flow

condition and the previous readings taken are invalid. Unless a no-flow condition can

be achieved, either through the operation of an additional shut-off downstream, or the

use of a temporary compensating bypass hose, accurate test results will not be

achieved.

Step 3 Check that the relief valve opens at a minimum pressure of 2 psid below inlet

pressure using the following procedure.

1. With the hoses hooked up the same as at the conclusion of Step 2 (3), slowly open

up the low pressure control needle valve B on the test kit and record the differential

pressure gage reading at the point when the water initially starts to drip from the relief

valve opening. This pressure reading should not be below 2 psid.

This completes the standard field test for a reduced pressure principle backflow

preventer. Before removal of the test equipment, the tester should ensure that they

open number 2 shut-off valve thereby reestablishing flow. Also, the test kit should be

thoroughly drained of all water to prevent freezing by opening needle valve B, and ball

valves A and C.

Figure 2 - Reduced Pressure Principle Backflow Preventer

Te

st

co

ck

N

o.

1

No

. 1

s

hu

t-o

ff

va

lve

Te

st

co

ck

N

o.

2

Ch

ec

k

va

lve

N

o.

1

Te

st

co

ck

N

o.

3

Ch

ec

k

va

lve

N

o.

2

Te

st

co

ck

N

o.

4

No

.2

s

hu

t-o

ff

va

lve

Ball Valve A

Ball Valve C

Needle

Valve B

High Pressure

Hose (Yellow)

Low Pressure

Hose (Red)

Vent Hose

(Blue)

Figure 3 - Reduced Pressure Principle Backflow Preventer

Te

st

co

ck

N

o.

1

No

. 1

s

hu

t-o

ff

va

lve

Te

st

co

ck

N

o.

2

Ch

ec

k

va

lve

N

o.

1

Te

st

co

ck

N

o.

3

Ch

ec

k

va

lve

N

o.

2

Te

st

co

ck

N

o.

4

No

.2

s

hu

t-o

ff

va

lve

Ball Valve A

Ball Valve C

Needle

Valve B

High Pressure

Hose (Yellow)

Low Pressure

Hose (Red)

Vent Hose

(Blue)

Temporary

Bypass Hose

(Black)

Figure 1 - Pressure Vacuum Breaker

Test cock

No. 2

Test cock

No. 1

Air inlet valve canopy

Loaded air inlet valve

No. 2 shut-off valve

Check valve

No. 1 shut-off valve

Ball Valve A

Ball Valve C

Needle

Valve B

Low

Pressure

Hose

(Red)

High Pressure

Hose (Yellow)

Vent Hose

(Blue)