Dwyer instruments, inc – Dwyer QPC User Manual

Page 2

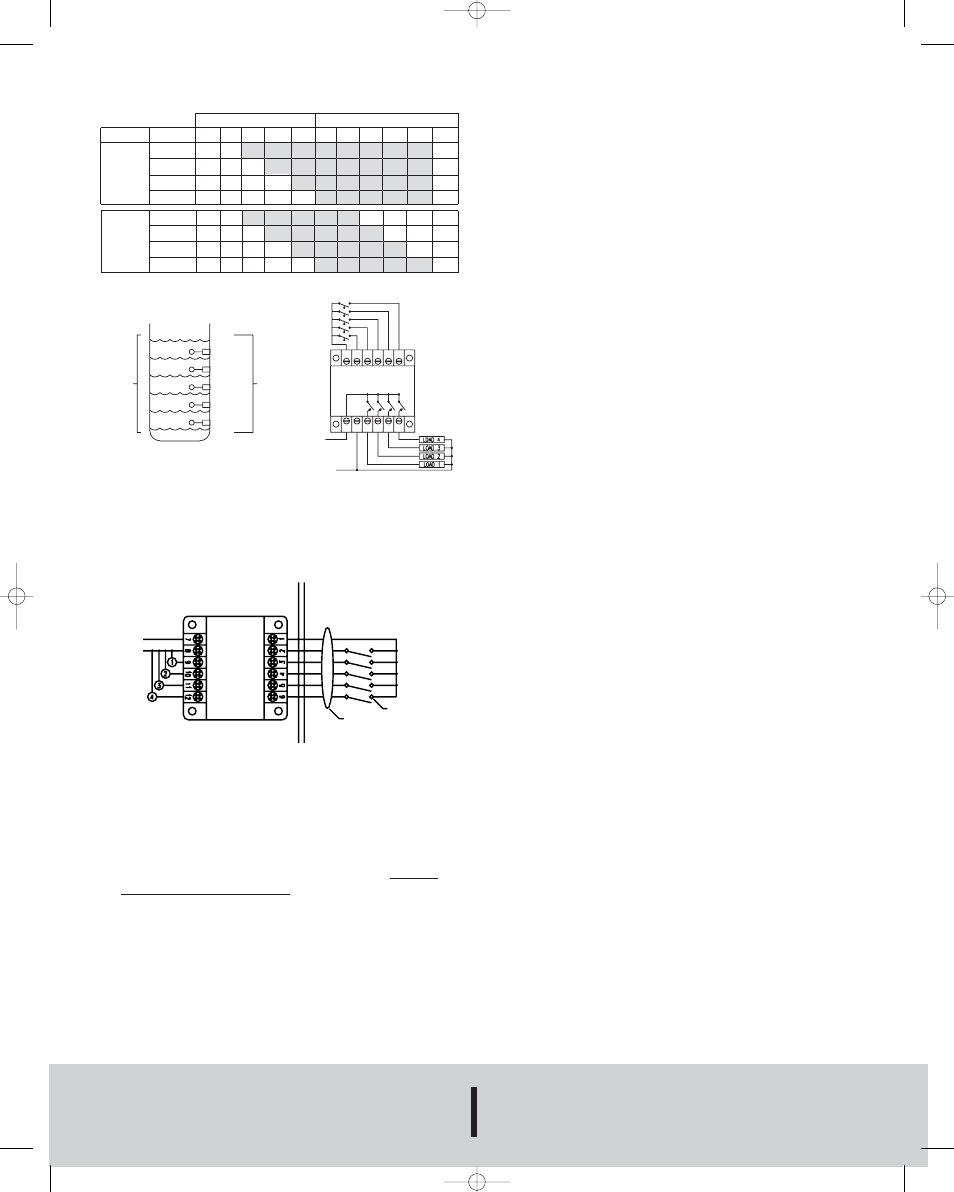

Increasing Level

Decreasing Level

A

B

C

D

E

F

E

D

C

B

A

Load 1

Off Off On

On

On On On On On On

Off

SOSO

Load 2

Off Off Off

On

On On On On On On

Off

Outputs Load 3

Off Off Off

Off

On On On On On On

Off

Load 4

Off Off Off

Off

Off On On On On On

Off

Load 1

Off Off On

On

On On On Off Off

Off

Off

FOFO

Load 2

Off Off Off

On

On On On On Off

Off

Off

Outputs Load 3

Off Off Off

Off

On On On On On Off

Off

Load 4

Off Off Off

Off

Off On On On On On

Off

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000

www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A.

Fax: 219/872-9057

e-mail: [email protected]

©Copyright 2007 Dwyer Instruments, Inc.

Printed in U.S.A.12/07

FR# R3-443592-01 Rev. 1

Figure A

SEQUENCING DESCRIPTION

SOSO - As the 3rd lag, 2nd lag, lag and lead switches open, the

loads remain energized. When the off switch opens, all four loads

de-energize simultaneously. If any switch fails to open, the loads

still de-energize when the off switch opens. The lead advances

one position each time the loads de-energize.

FOFO - When the 3rd lag switch opens, all four loads remain

energized. The 2nd lag switch opens next, and the lead load de-

energizes. When the lag switch opens, the lag load de-energizes.

Next, the lead switch opens and the 2nd lag load de-energizes.

Finally, the off switch opens and the 3rd lag load de-energizes. At

the end of each cycle, the lead advances one position for each

load energized during the cycle. For example: if loads one and two

cycle on and off, the lead will advance two positions. Load three

will be the lead load for the next cycle.

MAINTENANCE

Upon final installation of the Series QPC Quadraplex Pump

Controller, no routine maintenance is required. A periodic check of

the system calibration is recommended. The Series QPC is not

field serviceable and should be returned if repair is needed (field

repair should not be attempted and may void warranty). Be sure

to include a brief description of the problem plus any relevant

application notes. Contact customer service to receive a return

goods authorization number before shipping.

WATER

LEVEL

INPUT

LEVEL

SWITCH

F

E

D

C

B

A

3RD LAG

2ND LAG

1ST LAG

LEAD

OFF

HOT

NEUTRAL

3RD LAG

2ND LAG

1ST LAG

LEAD

OFF

1 2 3 4 5 6

7 8 9 10 11 12

EXCITATION TABLE

CONTROL DRAWING 194

HAZARDOUS LOCATION

CLASS I, GROUPS A, B, C, D; CLASS II,

GROUPS E, F, G, ; CLASS III

NON-HAZARDOUS LOCATION

HOT

NEUTRAL

CONTROL

VOLTAGE

LOADS

OFF

LEAD

LAG

2nd LAG

3rd LAG

SWITCH CONTACT SEE NOTE 3

INTRINSICALLY SAFE WIRING

SEE NOTES 1 AND 2

NOTES:

1. Maximum distance between unit and switch is 1000 feet.

2. All intrinsically safe wiring shall be separated from non-

intrinsically safe wiring. Refer to article 504 of the National

Electrical Code ANSI/ NFPA 70 for installation of intrinsically

safe wiring.

3. Switch contact shall be any non-energy strong or generating

mechanical switch type device containing no capacitance or

inductance.

Figure B

L-41 12/6/07 8:06 AM Page 2