Using accessory lift kit, Roof curb assembly, Minimum clearance requirements – Allied Air Enterprises (2 User Manual

Page 3: Typical condensate drain connection

506248-01

Page 3 of 14

Issue 0902

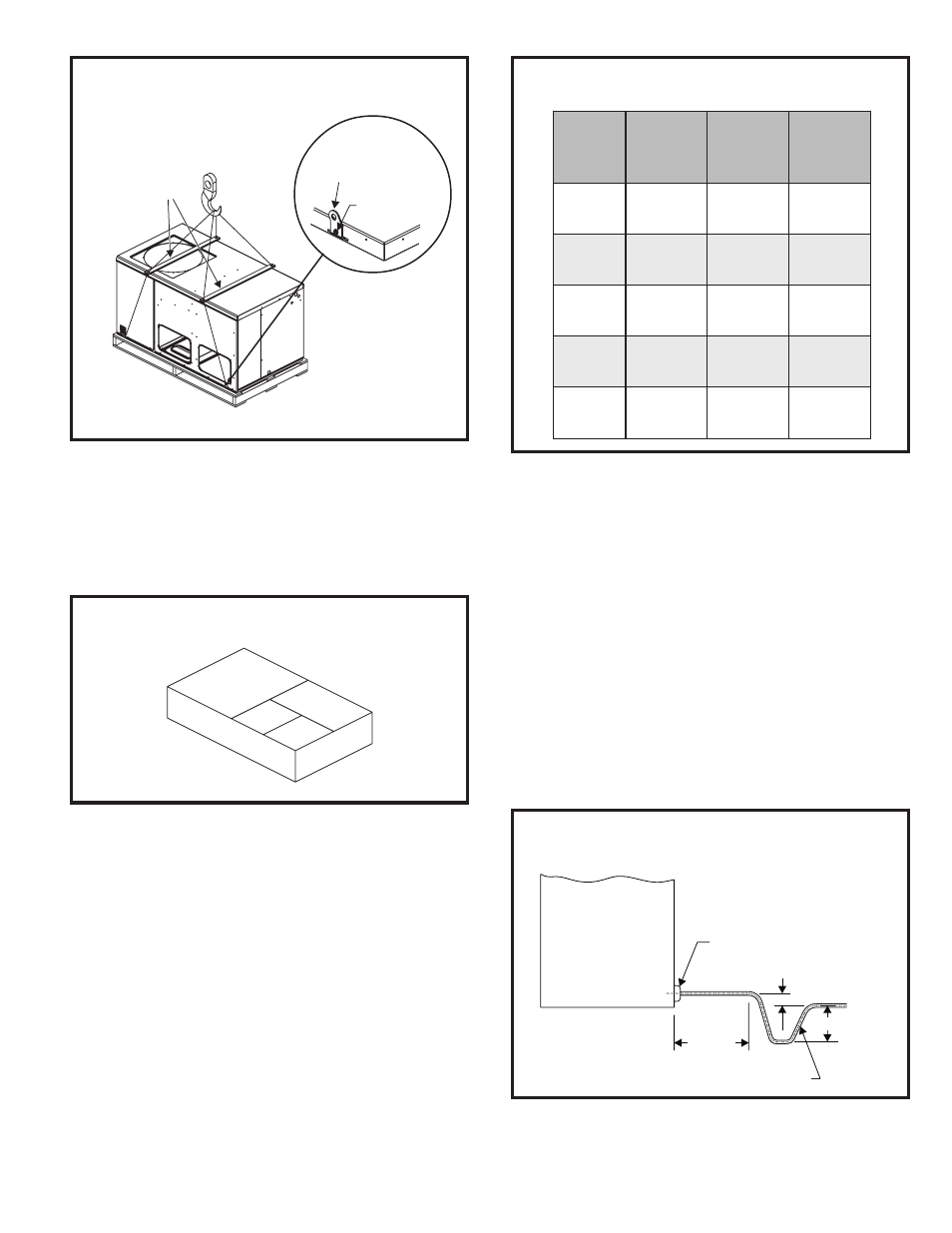

Using Accessory Lift Kit

Figure 1

Units may also be moved or lifted with a forklift while still in

the factory-supplied packaging. The lengths of the forks

of the forklift must be a minimum of 42".

Roof Curb Installation

If a roof curb is used, follow the manufacturer’s Installation

Instructions and be sure that all required clearances are

observed (see following Clearances section).

Clearances

All units require certain clearances for proper operation and

service. Refer to Table 1 for the minimum clearances to

combustibles as well as minimum clearances necessary for

servicing and proper unit operation.

In the U.S., units may be installed on combustible floors made

from wood or class A, B, or C roof covering material. In Canada,

units may be installed on combustible floors.

Service Access

Access to all serviceable components is provided by four

removable panels: filter compartment, blower compartment,

heater compartment, and top panel.

Condensate Drain

The PHP package unit is equipped with a 3/4" FPT coupling

for condensate line connection. Plumbing must conform to

local codes. Use a sealing compound on male pipe threads.

The condensate drain line must be properly trapped and

routed to a suitable drain. See Figure 3 for proper drain

arrangement. The drain line must pitch to an open drain or

pump to prevent clogging of the line. Seal around the drain

connection with suitable material to prevent air leakage into

the return air system.

To avoid possible

damage to unit

panels from lifting

clevis, place

packing material

between clevis

and panels before

lifting unit.

Spreaders

(Field Supplied)

Lifting Bracket

Accessory

Sheet Metal

Screw

Roof Curb Assembly

Figure 2

Table 1

o

T

e

l

b

i

t

s

u

b

m

o

C

l

a

i

r

e

t

a

M

r

o

F

e

c

i

v

r

e

S

r

o

F

r

e

p

o

r

P

n

o

i

t

a

r

e

p

O

t

n

o

r

F

"

0

"

8

4

"

3

r

a

e

R

"

0

"

4

2

"

3

r

e

s

n

e

d

n

o

C

d

n

E

"

0

"

4

2

"

3

r

e

w

o

l

B

d

n

E

"

0

"

0

3

"

0

p

o

T

"

0

"

6

3

"

6

3

Minimum Clearance Requirements

Unit

Drain Connection

Positive Liquid Seal Required

3.00" Min.

1.00" Min.

12.00"

Max.

Typical Condensate Drain Connection

Figure 3