Warning – Seametrics MJN-Series User Manual

Page 2

Position.

MJN-Series meters should be installed horizontally

with the register up. Vertical mounting will result in some de-

gree of under-measurement and shortened life of the bearings.

No upstream straight pipe is required.

Couplings.

Male NPT threaded couplings are included with

each meter. The threads on the end of the meter are IPS

straight threads one size bigger than the meter size. Though

it is possible to thread a standard pipe coupling directly onto

the meter for close coupling, the included couplings are much

preferable because they provide a union connection for meter

service. Be sure to use the included gasket between the end

of the meter and the coupling.

Connections.

MJNE and MJNR sensors are supplied with

a color coded output cable (see diagram, page 4). Optional

connectors can be ordered to plug directly into a Seametrics

control or LMI metering pump.

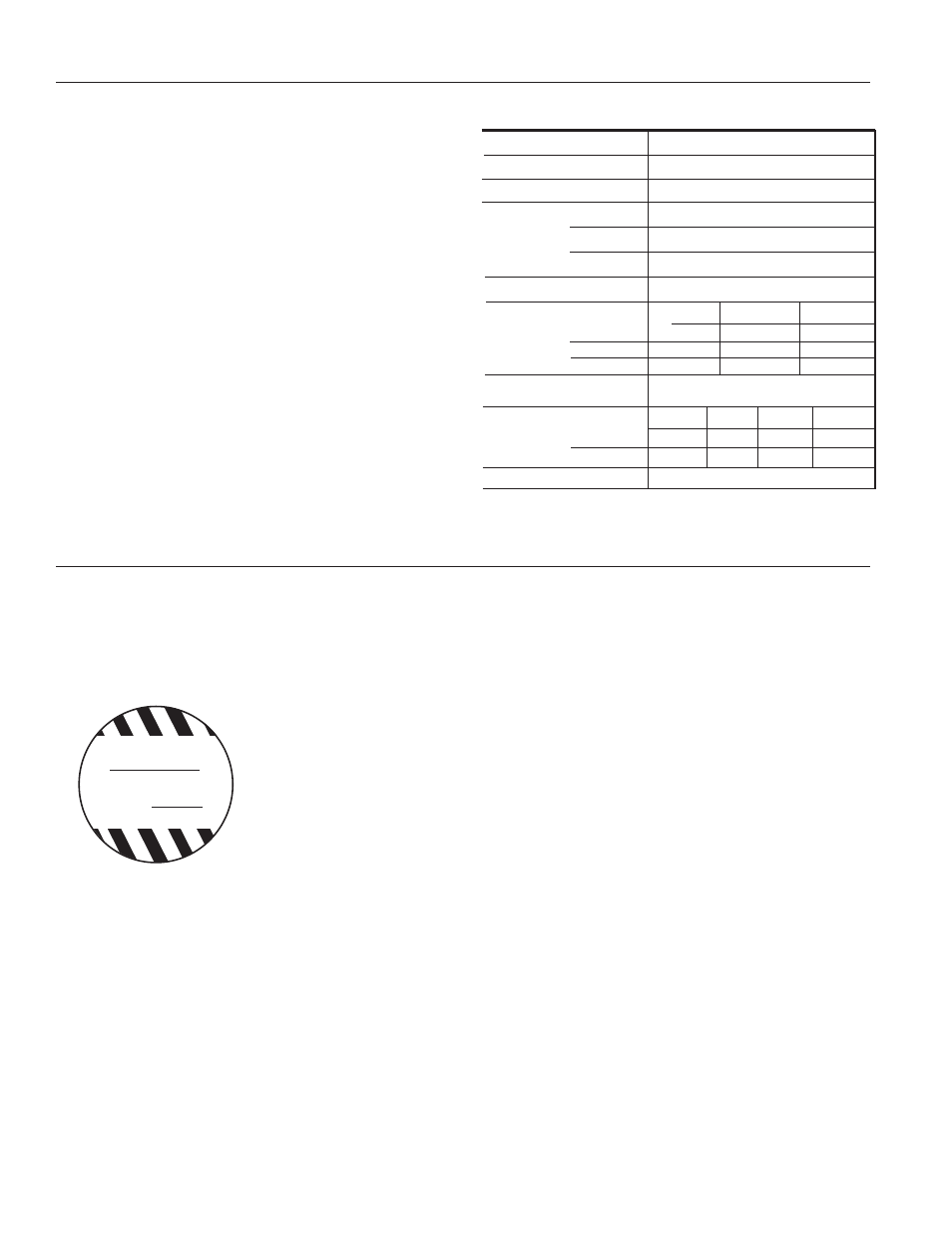

WARNING

DO NOT INSTALL

METER IN OVERHEAD

INDOOR PIPING OR

WHERE LEAKAGE

MAY CAUSE DAMAGE

GENERAL INFORMATION, INSTALLATION and MAINTENANCE

Page 2

GENERAL INFORMATION

MJN-Series meters use the internationally-accepted multi-jet

principle. A gear train drives the register totalizer dials. For

pulse output, one of the pointers is replaced by a magnet

arm, which is detected by an encapsulated sensor attached

to the outside of the lens.

MJNE

meters use a solid-state, long-lasting Hall-effect sensor,

which requires power. They are suited for use with Seametrics

controls and metering pumps (LMI for instance) that have

sensor power.

MJNR

meters use a reed switch. They provide a dry contact

closure and do not require power.

MJNT

meters do not have a sensor, and they totalize only.

INSTALLATION

Pulse Output.

Both MJNE and MJNR sensors respond

to a magnet that rotates on the face of the meter under

the lens. The sensor turns on and off once each time

the magnet passes under it. Sensors are designed for elec-

tronic control loads, and should not be used to switch power

loads or line voltages. See maximum current and voltage

ratings, under Specifications.

MAINTENANCE

Seametrics recommends all service to be performed by an

authorized distributor or the factory to maintain the integrity

of the protective tamper-proof wire-and-seal.

Inlet Strainer.

Clean the strainer yearly, or as required, de-

pending on water condition. Pull out the strainer or backflush

the meter to loosen trapped particulates.

Calibration.

Meters used for billing or billing exemp-

tion may be regulated by state or local authorities. New

meters are factory-tested to meet the AWWA C-708

Multi-Jet Meter accuracy specification. Some states

require retesting at various intervals, typically eight years for

3/4" meters, six for 1", and four for 1-1/2" and 2". Meters

used for control should be tested every 5-10 years. Testing

may be done by a local mobile meter service or in a private

or municipal meter shop. Changes in calibration should be

made at an authorized meter shop.

**CAUTION:

Excessive flow can cause breakage.

Do not exceed recommended maximums.

Caution:

These water meters are

not recommended for installation

in uninsulated suspended ceil-

ings where freezing is possible,

or in any overhead indoor piping

configuration where leakage may

cause damage.

SPECIFICATIONS*

6 mA at 12 Vdc (MJNE only)

105˚ F (40˚ C) max

150 psi operating

Eco-brass alloy

Engineered thermoplastic

Alnico

+/- 1.5% of reading

MJNE MJNR

MJNT

Hall-effect Reed switch Totalizer only

20 mA 20mA

n/a

24 Vdc 24 Vdc or Vac n/a

12’ (4 m) standard (2000’ maximum run)

3/4” 1” 1-1/2” 2”

0.22 0.44 0.88 1.98

22 52 88 132

NSF-61-G

Power

Temperature

Pressure

Materials Body

Internals

Magnet

Accuracy

Pulse Output

Sensor

Max Current

Max Voltage

Cable Length

Flow Rates (GPM)

Minimum

Maximum

Regulatory

*Specifications subject to change

Please consult our website for current data (www.seametrics.com).