Introduction – Precision Control Systems Hi-Temp IR 5209 User Manual

Page 5

1. Introduction

General Description

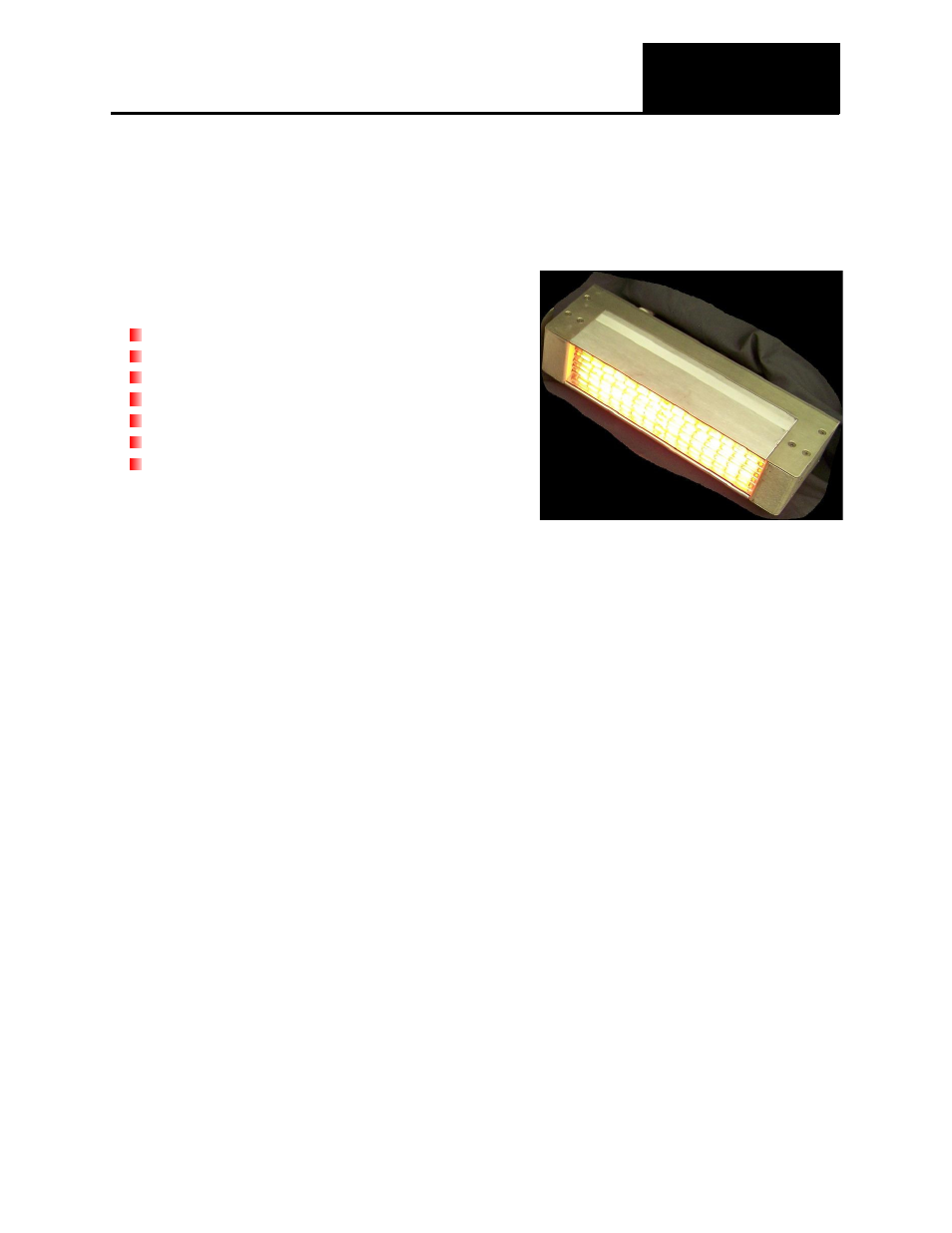

The Model 5209 Hi-TempIR

®

localized areas.

Typical applications for these heaters include:

Aerodynamic heating simulation

Thermal stress testing

Heating tensile and fatigue test specimens

Semiconductor wafer processing

Chemical processing

Stress relieving

Metal brazing processes

The Model 5209 includes the following major components:

Heater Module

The heater consists of a specular aluminum reflector that directs the infrared energy generated

by six ceramic end-seal, ‘T-3 style’, quartz halogen lamps factory

Heated lengths of 5-, 10-, and 16

5209. Additional lamps can be ordered separately from the heater.

Water Cooling

Adequate cooling water is required during operation of the Model 5209. Flexible tubing and

plumbing fittings are supplied with each heater for easy installation. Required cooling water

flow rates are listed in Specifications, Section 6.

Air Cooling

Compressed air cooling must also be supplied to the heater for proper operation. This cooling

air removes excess heat from around the lamp end

plumbing hardware is included with each heater. Required airflow rates and pressures are

listed in Specifications, Section 6

Removable Electrical Cable

The Model 5209 heater is electrically wired from the T3 lamps to intermediate terminal blocks

within the heater. Further wiring from each terminal block to a pinned connector on the top of

the heater is also included. A 10

heater that is designed to mate with the heater’s pinned connector. This cable is designed for

installation within an electrical junction box (optional item) or inst

designed power source.

1

heater is designed to provide high-intensity infrared heat onto

Typical applications for these heaters include:

Aerodynamic heating simulation

Heating tensile and fatigue test specimens

Semiconductor wafer processing

brazing processes

The Model 5209 includes the following major components:

The heater consists of a specular aluminum reflector that directs the infrared energy generated

3 style’, quartz halogen lamps factory- installed in the heater.

, and 16-inches (127-, 254-, and 406 mm) are offered for the Model

5209. Additional lamps can be ordered separately from the heater.

te cooling water is required during operation of the Model 5209. Flexible tubing and

plumbing fittings are supplied with each heater for easy installation. Required cooling water

es are listed in Specifications, Section 6.

ir cooling must also be supplied to the heater for proper operation. This cooling

air removes excess heat from around the lamp end-seals. Flexible tubing and matching

plumbing hardware is included with each heater. Required airflow rates and pressures are

, Section 6.

Removable Electrical Cable

The Model 5209 heater is electrically wired from the T3 lamps to intermediate terminal blocks

within the heater. Further wiring from each terminal block to a pinned connector on the top of

e heater is also included. A 10-ft. (3 m) removable electrical cable is supplied with each

heater that is designed to mate with the heater’s pinned connector. This cable is designed for

installation within an electrical junction box (optional item) or installed within an appropriately

Section 1

intensity infrared heat onto

The heater consists of a specular aluminum reflector that directs the infrared energy generated

installed in the heater.

, and 406 mm) are offered for the Model

te cooling water is required during operation of the Model 5209. Flexible tubing and

plumbing fittings are supplied with each heater for easy installation. Required cooling water

ir cooling must also be supplied to the heater for proper operation. This cooling

seals. Flexible tubing and matching

plumbing hardware is included with each heater. Required airflow rates and pressures are

The Model 5209 heater is electrically wired from the T3 lamps to intermediate terminal blocks

within the heater. Further wiring from each terminal block to a pinned connector on the top of

ft. (3 m) removable electrical cable is supplied with each

heater that is designed to mate with the heater’s pinned connector. This cable is designed for

alled within an appropriately

Section 1