Precision Control Systems Hi-Temp IR 5209 User Manual

Page 17

13

4. Loosen (do not remove) the setscrews in the ceramic

terminal blocks on each end of the heater corresponding to

the lead wires of the lamp to be replaced.

5. While holding the lamp, gently pull the lead wires out of the

ceramic terminal blocks and set the old lamp aside for

disposal.

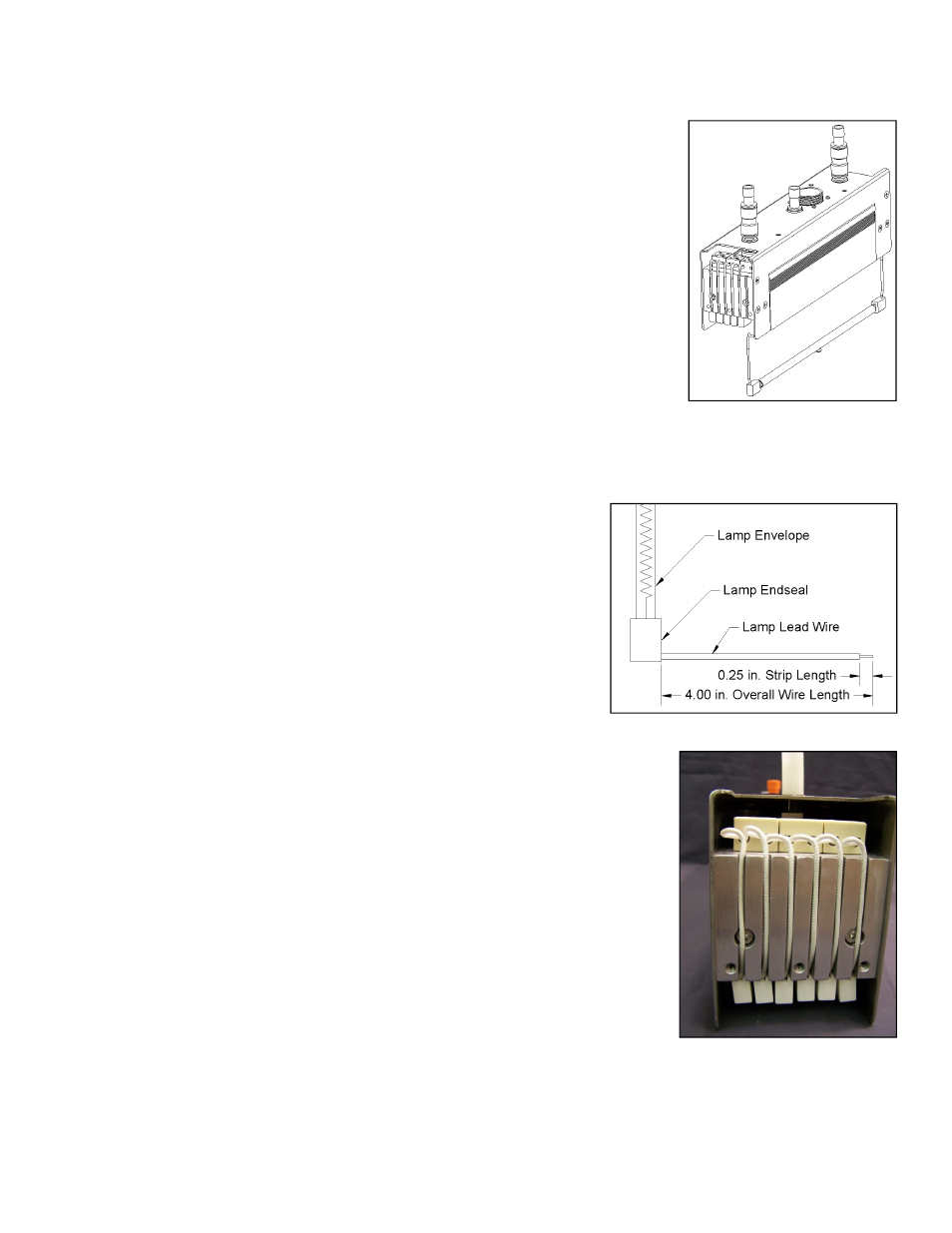

6. Both lead wires of the lamp need to be trimmed prior to

installation into the heater. Figure 5-3 details the proper

lengths to which the lead should be trimmed and stripped.

7. While holding the replacement lamp by the ceramic end

seals, place the lamp into the groove machined into each

lamp bracket plate located on each end of the heater. Orient the lamp so that the gas fill

tip , formed into the quartz tube of the lamp, points out away from the reflector.

8. Insert the bare wire of each insulated lamp lead

into the ceramic terminal block position that

previously held the old lamp. Push each lead wire

into the terminal block far enough so, that when

tightened, the setscrew will hold the lead securely.

9. Tighten the setscrews in each terminal block so the

lead wires are held securely. Note: tighten the

terminal block set screws to a torque of 0.6 feet –

lbs. (0.82 N-m).

10. Arrange the lead wire on each end of the lamp into the

groove machined into each of the aluminum cooling

manifolds located at either end of the heater. Each groove

corresponds to each of the individual lamps of the heater.

11. Form a loop within each lead along its length from the top

of the cooling manifold and the ceramic terminal block. This

loop will act as a strain relief within the lead during normal

operation of the heater.

12. Reinstall the quartz window within the heater by carefully

sliding the window into the grooves machined into the

heater reflector.

13. Reinstall both end covers and secure each to the heater

with the three screws per end cover.

Note: tighten the end cover screws to a torque of 1.7 ft.-

lbs. (2.3 N-m).

Figure 5-3

Figure 5-2

Figure 5-4