Tork, Digital time switch, Wiring diagrams – NSi Industries ES103A User Manual

Page 2: Warning, Specifications

TORK

DIGITAL TIME SWITCH

SPECIAL ENCLOSURE: -C -Y -FLG -O

TO SET CLOCK

Press MODE key until display shows CLK.

Press DAY key to select current day. Press HOUR key to select current hour.

Check A (AM) or P (PM). Press MIN key to select current minute. Press ENTER

key and the clock is set for current time and day.

TO SET SCHEDULE

If display does not show SCH, press mode key until display shows SCH.

Note: There are 7 ON and 7 OFF set points which alternate (set point #1 is ON;

#2 is OFF; #3 is ON).

The display will Indicate it is ready to receive SCH setpoint #1 which is an ON

event.

Press HOUR and MIN keys for the first ON setting (check for AM or PM).

Press ENTER key to store the information and display will indicate it is ready to

receive SCH setpoint #2 which is an OFF event.

Press HOUR and MIN keys for the first OFF setting. Then press ENTER key to

store the information and display will indicate it is ready to receive SCH set-

point #3 which is the next ON event.

Proceed for up to 7 ON and 7 OFF setpoints. Then press MODE key and unit

will go to the AUTO (run) mode.

In the AUTO mode, the unit will display current time and day as well as load sta-

tus (ON and OFF).

Note: When the unit is returned to the auto mode, check the load status of the current set-

ting. If it is showing OFF but should be ON, press the override key. The unit will correct itself

at the next scheduled event and no further alteration will be necessary.

TO SET SKIP DAYS

Press MODE key until display shows SKIP. Press DAY key and M (Monday)

starts flashing. Press SKIP key to set or delete a flashing day. Press DAY key to

advance the days. When all desired skip days are selected (showing solid on

LCD), press ENTER key.

Note: During skip days, only OFF events are executed. This will allow the load to turn off if it

was overridden ON during these days.

REVIEW/MODIFY

1. CLOCK - ALTER TIME. Press mode key until display shows CLK. Press

DAY, HOUR, and MIN keys to change to the correct time. Press ENTER.

2. SCHEDULE - REVIEW. Press mode key until display shows SCH. Press

ENTER key repeatedly to review all the scheduled entries. During the review,

any selected skip days will appear on the display with the word SKIP.

3. SCHEDULE - MODIFY. During the review (see previous section) any set-

point can be modified or deleted. Use the HOUR and MIN keys to modify.

Use the DELETE key to eliminate that event. Press ENTER key after each

modification.

4. SKIP DAYS - ADD/DELETE. Press MODE key until display shows SKIP. All

previously selected skip days will appear. To add or delete days, follow steps in

section titled “TO SET SKIP DAYS”.

OVERRIDE - TEMPORARY

In order to temporarily change the current ON or OFF status of a load, simply

press the override key when the unit is in the AUTO mode. The altered load sta-

tus will flash. Override is in effect until the next scheduled event. In order to can-

cel the override, press override key again.

OVERRIDE - LONG TERM

Press mode key until display shows MAN (manual). Normal schedule will not

be executed and the load status will remain unchanged as indicated. Press

the OVERRIDE key to obtain the correct status or to alter the load status.

®

UL

469D

LISTED

®

LR21743

MLI-162(B)

1 GROVE STREET, MT. VERNON, NY 10550 TEL: 914-664-3542

FAX: 914-664-5052

3

SPST

4

LOAD

120/277VAC

E101A

E120A

1

2

N

L

N

TIMER

SUPPLY

TIMER

SUPPLY

120/277VAC

3

4

5

SPDT

1

2

L

N

LOAD

LOAD

N

N

E103A

3

DPST

4

LOAD

208 OR 240VAC

1

2

L1

L2

TIMER

SUPPLY

6

5

DPST

TIMER

SUPPLY

3

5

6

120/277VAC

SINGLE PHASE

4

L1

L1

L1

N

1

2

LOAD

N

LOAD

N

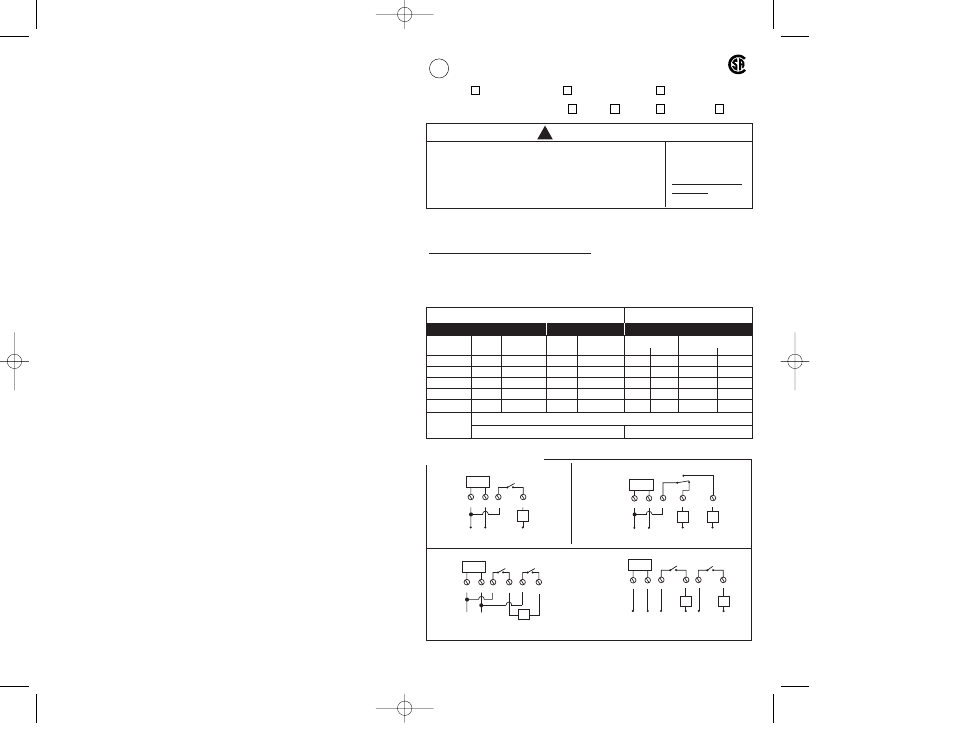

WIRING DIAGRAMS

ES101A ES120A ES103A

ES101A

ES103A

ES120A

WARNING

!

Lockout power at main panel before initial wiring or servicing

of this time switch and any equipment connected to it. More

than one disconnect point may be required. Install and use in

accordance with national and local electrical codes. Use cop-

per wire AWG #8-16 suitable for 75°C (167°F). Metal enclo-

sure must be properly grounded.

Insulator must be

replaced below before

turning on electricity.

Inform electrician if it

is missing.

SPECIFICATIONS

Input Voltage: 120/208 - 277VAC, 50/60Hz. (Jumper selectable), 4VA max.

User Selectable by Jumper Setting:

See caution on front page regarding

clock voltage selection and circle your input voltage below.

120V 208-277V

Dry Contact Ratings:

SERIES E101A (SPST) AND E103A (DPST)

SERIES E120A (SPDT)

TYPE

208-277

208-277

120VAC

208-277VAC

OF LOAD

120VAC

VAC

120VAC

VAC

N.O.

N.C.

N.O.

N.C.

Resistive

40A

40A

30A

30A

30A

30A

30A

30A

Inductive

40A

40A

30A

30A

30A

30A

30A

30A

Ballast

30A

20A

30A

20A

30A

10A

20A

10A

Tungsten

10A

–

10A

–

10A

2A

–

–

Pilot Duty

720VA

720VA

720VA

720VA

720VA 720VA

720VA

720VA

Motor

1 HP @ 120V; 1-1/2 HP @ 208V; 2 HP @ 240-277V

30A resistive @ 28 VDC

NO/NC 30A resistive @ 28 VDC

UL

CSA

UL and CSA

ES SERIES INSTRUCTIONS2003 11/18/03 5:01 PM Page 1