Martel Electronics DTM995 User Manual

Dtm 995, Dimensions, Lcd type k thermocouple indicator calibration

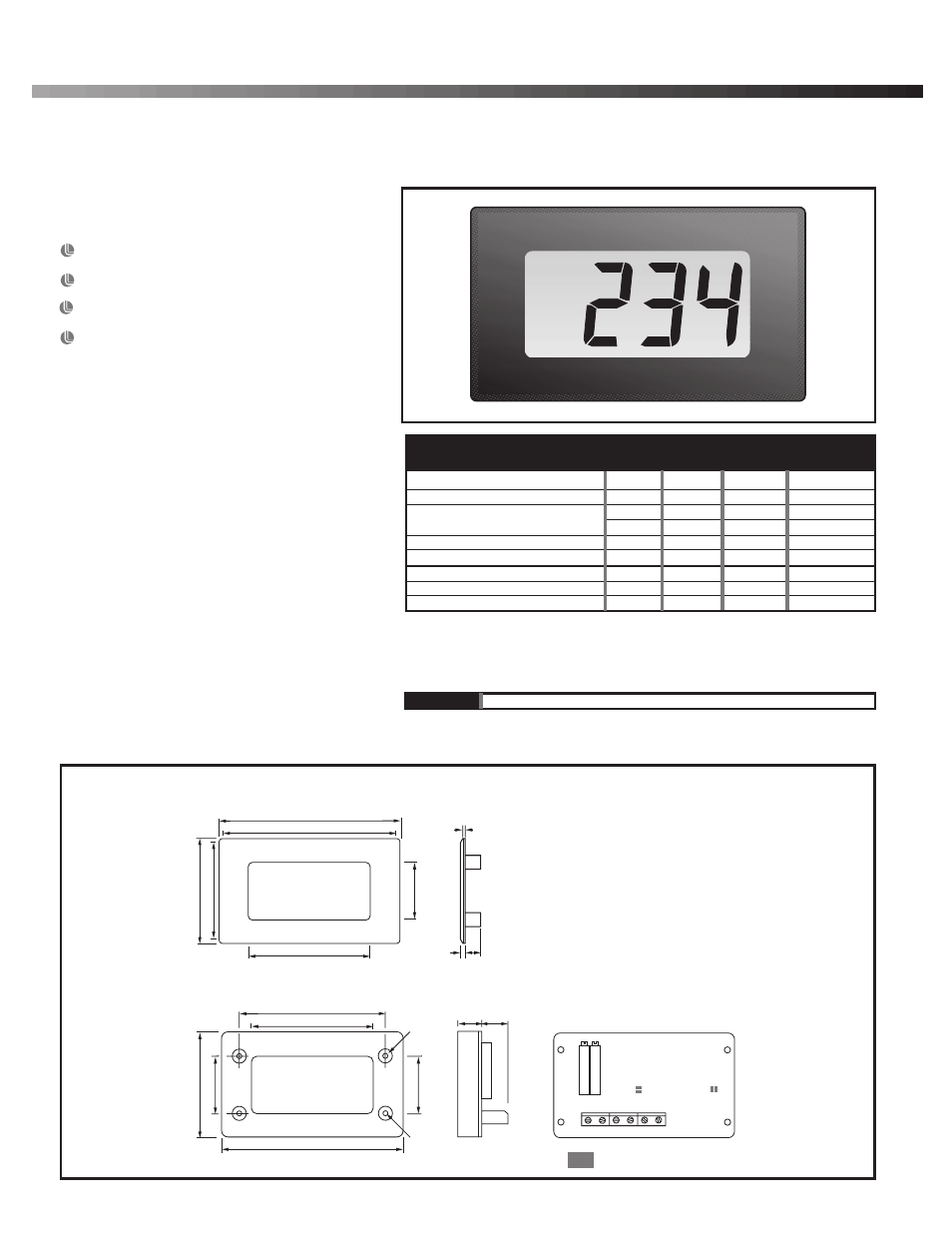

DIMENSIONS

All dimensions in mm (inches)

19mm (0.75“) Digit Height

Cold Junction Compensation

Simple Connection

LED Backlighting

DTM 995

LCD Type K Thermocouple Indicator

CALIBRATION

1.

Place thermocouple at 0°C and adjust OFFSET to

read 000.

2.

Place thermocouple at known reference

temperature, eg. 100°C and adjust CAL

to read 100.

3.

Repeat steps 1 and 2 until there are no more

adjustments of CAL and OFFSET required to

give desired readings.

In room temperature application adjust CAL to give the

same reading as a known temperature reference.

This meter will give a direct reading in °C from a K type (chromel-alumel) thermocouple sensor. The circuit uses a converter/amplifier

which has Cold Junction Compensation. Calibration is by two 20-turn cermet potentiometers which allow sensitive adjustment of the

instrument. The meter can also operate without a thermocouple to read room temperature. The meter is housed in a robust carrier,

which can be bolted in place or panel mounted using the low profile bezel, window and clips provided. The meter can also be backlit for

use in poor visibility.

Specification

Min.

Typ.

Max.

Unit

Accuracy (overall error)

***

1

% (±1 count)

Thermocouple measurement range

-50

+600

°C

-58

+1112

°F

Power supply voltage (V+ to V-)**

7.5

9.0

24

V

Operating temperature range

*

0

50

°C

Temperature stability

0.05

°C/°C

Supply current

3.5

mA

Supply current with backlighting

55

mA

Stock Number

Standard Meter

DTM 995

CONNECTOR SOURCING GUIDE

Screw Terminals - No Connector Required

METHOD

ON-BOARD SOLDER LINKS

*

Module temperature

**

*** To ensure maximum accuracy, re-calibrate periodically

5V supply option available - Contact Sales for details

REAR

VIEW

T-

(blue)

T+

(brown)

V-

LP

-

V+

LP+

CAL OFFSET

61.5 (2.42)

51.0 (2.01)

Ш5.7

(0.22)

24.5

(0.96)

24.0

(0.94)

39.0

(1.54)

Ш3.0

(0.12)

71.5 (2.81)

d

e

76.0 (2.99)

72.5 (2.85)

40.5

(1.59)

44.0

(1.73)

24.0

(0.94)

51.0 (2.01)

a

b c

Panel cut-out 72 x 40 (2.83 x 1.57)

Maximum panel thickness 3mm (0.12).

a.

1.0 (0.04)

b.

2.0 (0.08)

c.

6.5 (0.26)

d. 11.5 (0.45)

e. 13.0 (0.51)

2

3

SAFETY

The user must ensure that the incorporation of the DPM into the user’s equipment conforms to the relevant sections of BS EN 61010 (Safety Requirements

for Electrical Equipment for Measuring, Control and Laboratory Use).

www.lascarelectronics.com