Installation - electronic (pulse output only), Installation - electronic (relay output only), Table 1.: wiring connections – Lake Monitors FlowStat ES Sensor (Plastic) User Manual

Page 6: Wire color connection red +12-35 v

Installation - Electronic (Pulse Output Only)

The FlowStat pulse output circuit is a three-wire DC-powered design that

transmits a frequency proportional to flow rate. The circuit operates on 5-

24 V

DC

and will consume a maximum of 25 mA from the power supply.

1. Connect the red wire (pin 1 for units with the electronic disconnect

option) from the sensor to the positive terminal of the 5-24VDC

power supply.

2. Connect the black wire from the transmitter (pin 2 for units with the

electronic disconnect option) to the negative terminal of the 5-24

V

DC

power supply.

3. Connect the green wire from the transmitter (pin 3 for units with

electronic disconnect) to the (+) pulse input of the data acquisition

device. This connection may be labeled "Pulse In" or "DC Input"

on some devices.

4. If applicable, connect the negative side of the power supply to the

negative side of the pulse input.

5. Apply power to the system.

6. If everything is operating correctly, the data acquisition device should

begin "counting" pulses when fluid starts flowing through the sensor.

If the data acquisition device is not “counting”:

check wiring terminations for good connections

verify correct supply voltage and current

7. The installation should be complete. The relationship between the

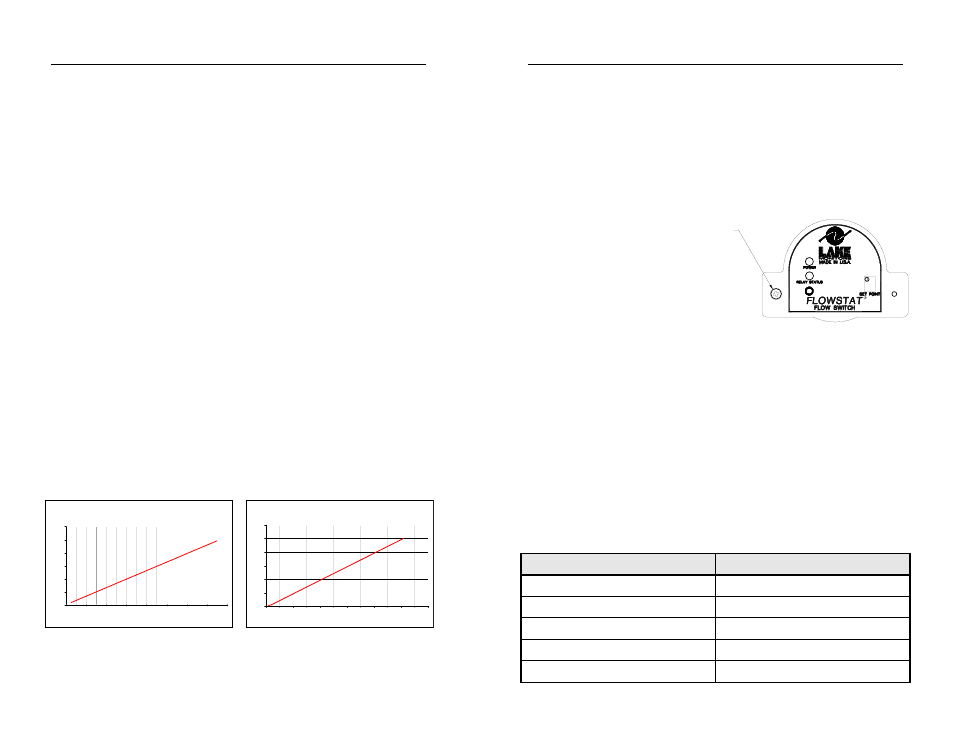

frequency output and flow rate is shown in the graphs above.

(6)

Flow Rate vs. Frequency Output

Standard 1/2" NPTF Units

0

10

20

30

40

50

60

0

2

4

6

8

10

12

14

16

Flow Rate (GPM)

F

re

q

u

e

n

c

y

(H

z

)

Flow Rate vs. Frequency Output

Standard 3/4" & 1" NPTF Units

0

10

20

30

40

50

60

0

10

20

30

40

50

60

Flow Rate (GPM)

F

re

q

u

e

n

c

y

(H

z

)

Installation - Electronic (Relay Output Only)

1. Connect the red wire from the sensor to the positive terminal of the

12-35 V

DC

power supply.

2. Connect the black wire from the transmitter to the negative terminal

of the 12-35 V

DC

power supply.

3. (Versions with stainless steel sensor body only) Be sure to properly

ground the FlowStat sensor by using the ground screw shown

in Illustration 2 to connect the sensor body Earth ground.

This step may be

unnecessary if the

piping system that the

flow sensor is plumbed

into is already connected

to Earth ground.

4. Wire the appropriate

relay contacts to the load

that is to be switched per Table 1 below.

5. If the unit is operating correctly, the green power indication LED

and the red relay status LED should illuminate after the DC supply

voltage is turned on. As fluid flow is increased above the factory-

adjusted set point, the red relay status LED should turn off.

If the LEDs do not illuminate when power is applied:

check wiring terminations for good connections

verify that the DC supply voltage is between 12 and 35 V

DC

Table 1.: Wiring Connections

(7)

Wire Color

Connection

Red

+12-35 V

DC

Black

DC Ground

Green

Relay Common

White

Relay Normally Closed Contact

Brown

Relay Normally Open Contact

Illustration 2

GROUND

SCREW