Lake Monitors ClearView+ Flow Meter (Polysulphone) User Manual

Page 3

Basic Application Information

The flow meter can be installed directly in the fluid line without flow

straighteners or special piping. The meter is used to measure the flow

rate of most liquids which do not contain particles greater than 74 micron.

1) The casing and union retainers are made of either Polycarbonate

or Polysulphone materials permitting use with a variety of media.

Use of mild detergent to clean the meter body is encouraged to

prevent damaging the label or associated components.

2) The meter may be mounted in the most convenient location, in any

orientation to allow easy access for reading and maintenance.

3) The ClearView

™

meter should NOT be mounted near hot pipes or

equipment which can cause damage to the pressure vessel.

4) The ClearView

™

meter should not be mounted in a manner such

that piping misalignment or other system components can exert

force or produce a bending moment on the pressure vessel.

5) To retain accuracy and repeatability internal moving parts are

closely toleranced and require filtration of at least 74 micron or a

200 mesh screen.

(3)

tubular, with all internal wetted parts sealed within the body casing

(5). Running through the center of the body casing is a tapered center

shaft which is centered in the bore. Encircling the shaft is a sharp-

edged, floating metering poppet (6). The metering poppet is held in

the “no flow” position by the biased return spring (4). As the flow

moves through the meter it creates a pressure differential across the

floating orifice disk, forcing the disk and transfer magnet against the

return spring. As flow increases, the pressure differential across the

metering poppet increases, forcing poppet to move along the tapered

center shaft. As flow decreases, the biased return spring forces the

poppet down the tapered center shaft, returning to the “no flow” position.

Reading the Meter

Notice the black reference line which runs 360° around the metering

poppet. This reference line moves under the scale in direct relation to

the movement of the poppet. When fluid is flowing, the flow rate

through the meter is read by lining up the black reference line with

the closest rate line on the flow scale.

Specific Gravity or Density Effect

Standard meters are calibrated for either WATER with a specific gravity of

1.0 or OIL with a specific gravity of .873. The floating disk meter is

affected by fluid density as are most other similar type meters. Lake’s

meters have less of this effect because of the sharpness of the floating

orifice disks being used. The indicated flow reading will read high for

heavier fluids and low for lighter fluids. A corrective factor can be applied

to the standard scale or a special scale can be added at a slight

additional costs. When measuring fluids with other specific gravities, the

basic equations below can be used to develop corrected readings.

(6)

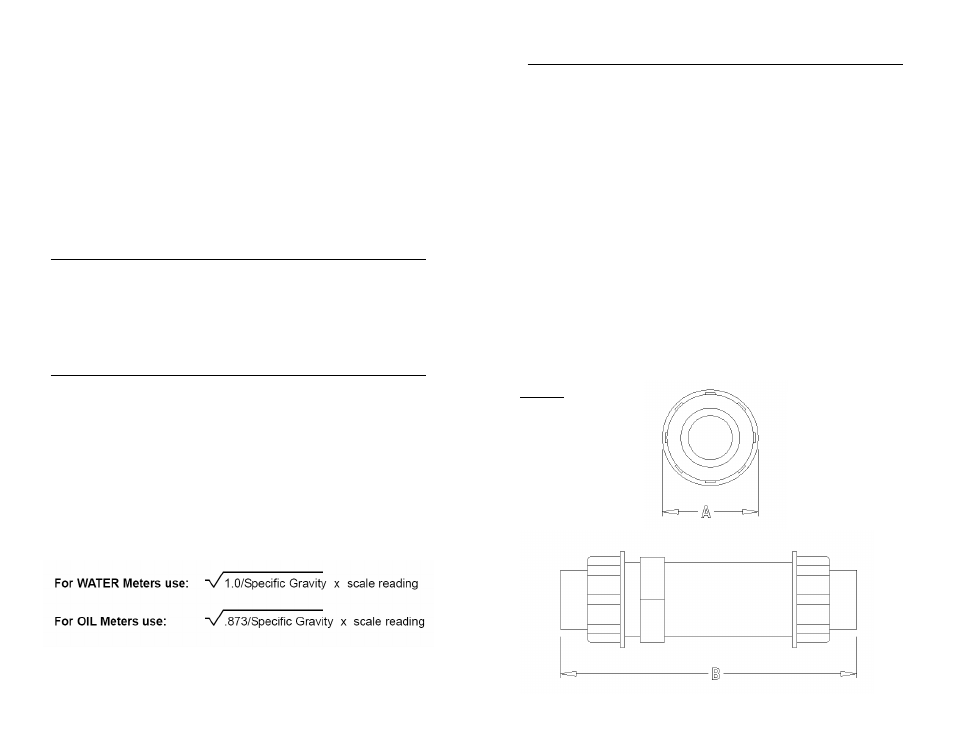

Figure 1:

Mechanical Dimensions