Contamination and filtration, Mechanical dimensions, Performance – Lake Monitors ClearView+ Flow Meter (Polysulphone) User Manual

Page 2: Recommended filtration, Stabilized contamination, Contamination sources

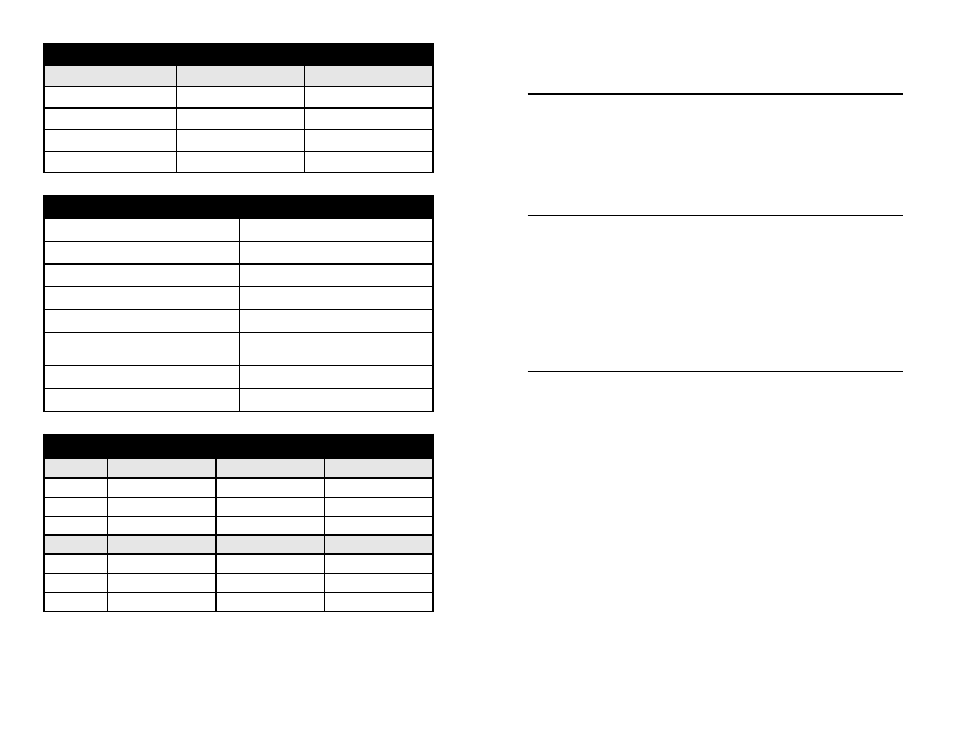

Mechanical Dimensions*

DIM

½" Male

¾" Male

1" Male

A

2-7/16" (62mm)

2-7/16" (62mm)

2-7/16" (62mm)

B

7-11/16" (195mm)

8-1/32" (204mm)

8-3/32" (206mm)

Port Size

NPTF ½", SAE #8

NPTF ¾", SAE #12

NPTF 1", SAE #16

DIM

½" Female

¾" Female

1" Female

A

2-7/16" (62mm)

2-7/16" (62mm)

2-7/16" (62mm)

B

7-5/32" (182mm)

7-9/16" (192mm)

7-9/16" (192mm)

Port Size

NPTF ½", SAE #8

NPTF ¾", SAE #12

NPTF 1", SAE #16

Performance

Measuring accuracy:

±5% of full-scale

Repeatability:

±1% of full-scale

Flow Measuring Range:

1-30 GPM (5-110 LPM)

Turn Down Ratio (All Ranges:)

10:1

Maximum operating pressure:

325 PSIG (22.4 bar)

Maximum operating temperature:

ClearView H2O: 200°F (93°C)

ClearView+: 250°F (121°C)

Pressure Differential:

See graph on right.

Filtration requirements:

74 Micron (200 U.S. mesh) min.

Materials of Construction (Wetted Components)

ClearView H

2

O

ClearView +

End Ports

Brass

Brass

Seals

Buna-N

Buna-N

Spring

Stainless Steel

Stainless Steel

Indicator and Casing

Polycarbonate

Polysulphone

(2)

CONTAMINATION AND FILTRATION

Recommended Filtration

The manufacturer recommends system filtration of at least 74 micron

filter or a 200 mesh screen. It has been found that if inadequate filtration

has caused meter failure, it will normally fail in the open position. Some

systems may require a magnetic filter. IMPORTANT: Meter damage

caused by excessive contamination is not covered under warranty.

Stabilized Contamination

The goal of filtration is to create effective protection from system

contamination. Proper filtration stabilizes contamination to allow fluid

components to function properly. A fluid system is considered

stabilized when, “contamination in” equals “contamination out”. Proper

filtration must reduce initial contamination to a stabilized level within

an acceptable time period. the system should be stabilized in time to

prevent premature wear or damage to meter components.

Contamination Sources

Fresh Fluid

When fresh fluid is stored in holding tanks, it may be contaminated

with scale or metal flakes from inside the tank. To prevent this type of

contamination, be sure to filter fresh fluid before adding to the system.

New Machinery Contamination

When building new machines, a certain amount of built-in

contamination is unavoidable. Typical built-in contamination consists

of dust, dirt, chips, fiber, and sand, flushing solutions, moisture, weld

splatters and pipe sealants. Flushing the system before operation can

reduce contamination, but cannot eliminate it totally.

Unless the system is flushed at a high velocity, some contamination

will not be dislodged until the system is in operation. System

contamination can cause fluid component malfunction.

(7)

*Refer to Figure 1 at right.