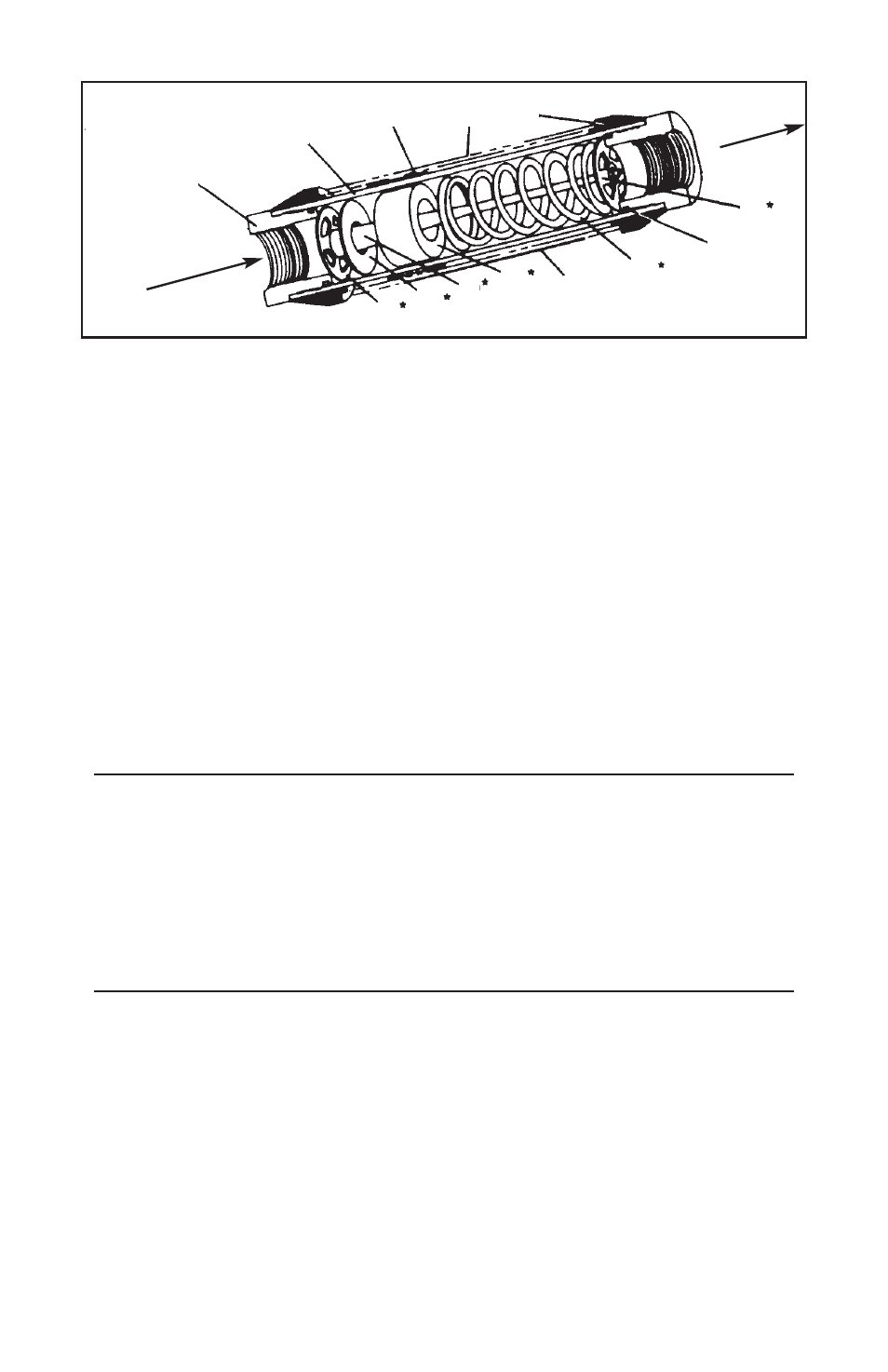

Reading the meter, Specific gravity or density effect, Illustration 1 – Lake Monitors Case Drain Monitor User Manual

Page 8

1.

End Porting

8.

Flowing Sharp-Edged Orifice Disk

2.

Body Casing

9.

Tapered Center Shaft

3.

Magnet Follower

10. Transfer Magnet

4.

Window Tube

11. Scale

5.

Window Seal

12. Return Spring

6.

Seal Assembly

13. Retainer Ring

7.

Pilot Disk

* Cartridge contains: 7, 8, 9, 10, 12 & 13

Reading the Meter

Notice the black reference line which runs 360° around the white

magnetic follower. This reference line moves under the scale in direct

relation to the movement of the internal orifice disk. When fluid is

flowing, the flow rate through the meter is read by lining up the black

reference line with the closest rate line on the external flow scale.

Specific Gravity or Density Effect

Standard meters are calibrated for either WATER with a specific

gravity of 1.0 or OIL with a specific gravity of .873. The floating disk

meter is effected by fluid density as are most other similar type

meters. Lake’s meters have less of this effect because of the sharp-

ness of the floating orifice disks being used.

(8)

12

11

10

8

7

9

13

6

5

4

3

2

1

Flow

Direction

Flow

Direction

FLOW METER

(CROSS SECTION)

Illustration 1