KYORITSU 8325F User Manual

Voltage sensor series, Kew 8325f, Instruction manual

1. SAFETY WARNINGS

This instrument has been designed and tested according

to IEC61010: Safety requirements for Electronic Measuring

Apparatus, and delivered in the best condition after passing

quality control tests. This instruction manual contains warnings

and safety rules which have to be observed by the user to

ensure safe operation of the instrument and to maintain it in safe

condition. Therefore, read through these operating instructions

before using the instrument.

WARNING

●

Read through and understand instructions contained in this

manual before using the instrument.

●

Keep the manual at hand to enable quick reference

whenever necessary.

●

The instrument is to be used only in its intended applications.

●

Understand and follow all the safety instructions contained in

the manual.

It is essential that the above instructions are adhered to. Failure

to follow the above instructions may cause injury, instrument

damage and/or damage to equipment under test.

The symbol indicated on the instrument, means that the user

must refer to the related parts in the manual for safe operation of

the instrument. It is essential to read the instructions wherever the

symbol appears in the manual.

DANGER is reserved for conditions and actions that are

likely to cause serious or fatal injury.

WARNING is reserved for conditions and actions that can

cause serious or fatal injury.

CAUTION is reserved for conditions and actions that can

cause injury or instrument damage.

Instruction Manual

Voltage Sensor Series

KEW 8325F

Flicker Sensor

DANGER

●

Never make measurement on a circuit in which the electrical

potential exceeds AC600V.

●

Do not make measurements when a thunder is rumbling.

Stop measurements immediately and disconnect the

instrument from the devices under test.

●

Do not attempt to make measurements in the presence of

flammable gasses.

Otherwise, the use of the instrument may cause sparking,

which can lead to an explosion.

●

Be especially careful about the possible shorting where the

measured conductor is not insulated.

●

Never attempt to use the instrument if its surface or your

hand is wet.

●

Remove the Measuring terminals from the circuit under test

before connecting / inserting the Output connector.

●

Do not exceed the maximum allowable input of any

measuring range.

●

Confirm a proper operation of this sensor on a well-known

power source before taking countermeasures against the

measured results.

WARNING

●

Never attempt to make any measurement if any abnormal

conditions, such as a broken cover or exposed metal parts

are present on the instrument.

●

Do not install substitute parts or make any modification to the

instrument. Return the instrument to your local KYORITSU

distributor for repair or re-calibration in case of suspected

faulty operation.

●

Keep your fingers and hands behind the safety barrier during

measurements.

CAUTION

●

Do not step on or pinch the cord, or it may damage the jacket

of cord.

●

Grasp the connector to remove the output terminal from the

instrument.

●

Put the instrument on a stable place where is free from

vibrations or shocks.

●

Firmly fix the Sensor unit and Measuring terminal so that

they don't fall off due to the weight of sensor or test leads.

●

Keep away Floppy Disks, Magnetic Cards, PCs and Displays

from the magnet, which is attached to the backside of the sensor.

●

Do not expose the instrument to direct sunlight, high

temperatures, humidity or dew.

●

Not to give shocks, such as vibration or drop, which may

damage the instrument.

●

Use a damp cloth with neutral detergent for cleaning the

instrument. Do not use abrasives or solvents.

Safety symbols

Must refer to the instructions in the manual for safety

Indicates a Instrument with double or reinforced insulation

Indicates AC

◊ Measurement categories(Over-voltage categories)

To ensure safe operation of measuring instruments, IEC 61010

establishes safety standards for various electrical environments,

categorized as CAT.I to CAT.IV, and called measurement

categories. Higher-numbered categories correspond to electrical

environments with greater momentary energy, so a measuring

instrument designed for CAT.III environments can endure

greater momentary energy than one designed for CAT.II.

CAT.I : Secondary electrical circuits connected to an AC

electrical outlet through a transformer or similar device.

CAT.II : Primary electrical circuits of equipment connected to an

AC electrical outlet by a power cord.

CAT.III : Primary electrical circuits of the equipment connected

directly to the distribution panel, and feeders from the

distribution panel to outlets.

CAT.IV : The circuit from the service drop to the service

entrance, and to the power meter and primary

overcurrent protection device (distribution panel).

2. FEATURES

• This is a Voltage Sensor designed for KEW6310 to measure AC

voltage up to 600V.

• Use with Power Quality Analyzer (KEW6310) enables flicker

measurement according to IEC61000-4-15 (Flickermeter –

Functional and design specifications).

• Designed to following international safety standards:

IEC61010-1 Measurement Category (CAT.) III 600V

IEC61010-031 Requirements for hand-held probes

• Internal differential amplifier is equipped, enabling floating

voltage measurement.

3. SPECIFICATIONS

• Max. input voltage

AC600Vrms, 848.4V Peak

• Input system

Differential input (can measure floating

voltages)

• Output voltage

AC600mV/ AC600V (Output/Input: 1mV/ V)

• Measuring ranges and accuracy

Measuring Range

Frequency range

Accuracy

6 ~ 600V

50/ 60Hz

±0.5%rdg±0.1mV

40Hz ~ 1kHz

±1.5%rdg±0.2mV

• Temperature and Humidity Ranges(guaranteed accuracy):

23ºC±5ºC, relative humidity 85%or less (without condensation)

• Operating Temperature and Humidity Ranges:

0~40ºC, relative humidity 85%or less (without condensation)

• Storage Temperature and Humidity Ranges

-20~60ºC, relative humidity 85%or less (without condensation)

• Power supply (supplied via output terminal)

DC : ±(5V±10%)

• Current consumption 1mA (Typ.)

• Input impedance

Approx.3.2MΩ

• Output impedance

Approx.1kΩ

• Location for use

Altitude up to 2000m, Indoors

• Safety Standard

IEC/EN61010-1:2001 Measurement Category (CAT.) III 600V

Pollution Degree 2

IEC/EN61010-031:2002

EN61326:2001 (EMC Standard)

• Withstand Voltage

AC5350Vrms (50/60Hz)for 5sec.

(between Measuring terminal and

enclosure)

• Insulation Resistance 50MΩor greater at 1000V

(between Measuring terminal and

enclosure)

• Dimension & weight 87(L) x 26(W) x 17(D)mm (excluding

protrusions)

Approx. 135g

• V,COM Cable length Approx. 0.9m

• Output Cable length Approx. 1m

• Output Connector

MINI DIN 6PIN

• Accessories

Instruction manual

• Option

7197(small Alligator clip)

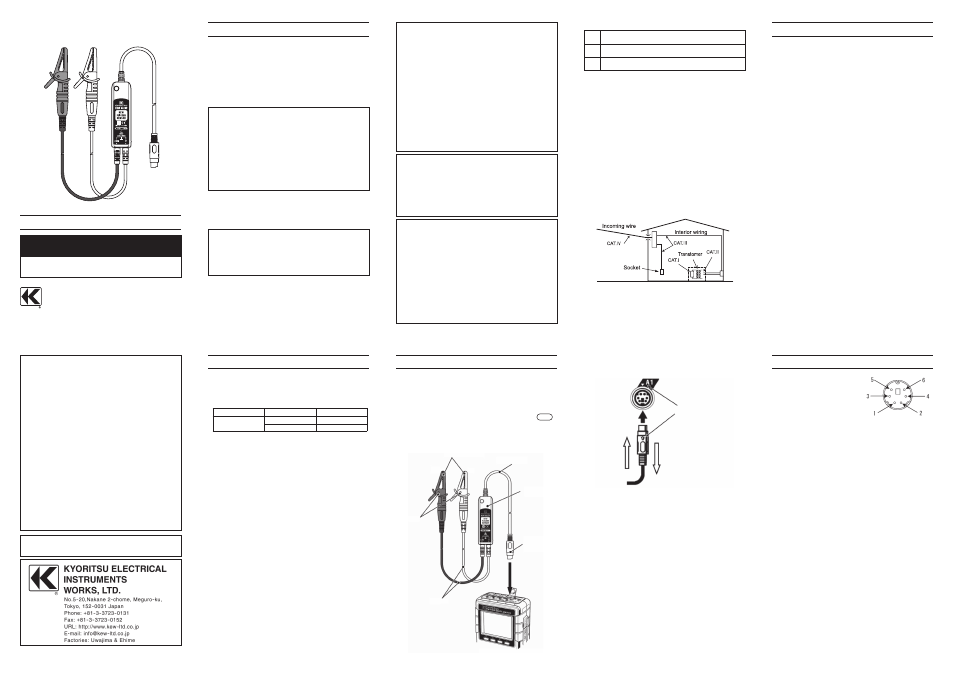

4. HOW TO USE/ SENSOR LAYOUT

Connect the Output connector to the Input terminal (A1) of the

Power Quality Analyzer (KEW6310).

This sensor operates only at A1 terminal. Do not use 2pcs or

more of KEW8325F at the same time.

Clip the V and COM measuring terminals onto the conductor

under test.

Start KEW6310 and select Flicker measurement at “

QUALITY

”

menu.

Detailed operating instructions are given in the Instruction

manual for KEW6310.

5. DIN Plug pin assignment

1: +DC power supply Pin (+5V)

2: -DC power supply Pin (-5V)

3: GND Pin

4: No use

5: Output signal Pin

6: Sensor recognition pin

(Resistance between Pin 3 and Pin 6: 20kΩ)

* Above figure shows the pin assignment seeing the Clamp sensor

from output connector part. The figure of the pin assignment of

connection terminal is symmetrical to above figure.

07-08

92-1935

DISTRIBUTOR

Kyoritsu reserves the rights to change specifications or designs

described in this manual without notice and without obligations.

KYORITSU ELECTRICAL INSTRUMENTS WORKS, LTD.,

TOKYO, JAPAN

Measuring terminal

(COM)

(V)

Barrier

Test lead

Power Quality Analyzer (KEW6310)

Output cable

Sensor

Output connector

Output signal

Power supply

Match the arrow marks