KYORITSU 8127 User Manual

Power clamp sensor

INSTRUCTION MANUAL

MODEL 8124/8125/8126/8127

POWER CLAMP SENSOR

Series

POWER CLAMP SENSOR

MODEL 8127

MODEL 8126

MODEL 8125

MODEL 8124

KYORITSU ELECTRICAL INSTRUMENTS WORKS, LTD.,

TOKYO, JAPAN

1. Safety warnings

○

This instrument has been designed, manufactured and

tested according to IEC 61010: Safety requirements for

Electronic Measuring apparatus, and delivered in the best

condition after passing quality control tests. This

instruction manual contains warnings and safety rules

which have to be observed by the user to ensure safe

operation of the instrument and to maintain it in safe

condition. Therefore, read through these operating

instructions before using the instrument.

WARNING

●Read through and understand instructions contained

in this manual before using the instrument.

●Keep the manual at hand to enable quick reference

whenever necessary.

●The instrument is to be used only in its intended

applications.

The operating instructions described in the manual

must be observed.

●Understand and follow all the safety instructions

contained in the manual.It is essential that the above

instructions are adhered to. Failure to follow the

above instructions may cause injury and or

instrument damage.

○

The symbol

indicated on the instrument, means that

the user must refer to the related parts in the manual for

safe operation of the instrument. It is essential to read the

instructions wherever the

symbol appears in the

manual.

DANGER

is reserved for conditions and actions

that are likely to cause serious or fatal

injury.

WARNING is reserved for conditions and actions

that can cause serious or fatal Injury.

CAUTION

is reserved for conditions and actions

that can cause minor injury or

instrument damage.

DANGER

●Never make measurement on a circuit in which the

electrical potential exceeds AC300V using

MODEL8127 and AC600V using MODEL8124, 8125

and 8126.

●Do not make measurement when thunder rumbling. If

the instrument is in use, stop the measurement

immediately and remove the instrument from the

measured object.

●Do not attempt to make measurement in the

presence of flammable gasses. Otherwise, the use of

the instrument may cause sparking, which can lead

to an explosion.

●The transformer jaws are made of metal and their

tips are not completely insulated. Be especially

careful about the possible shorting where the

measured object has exposed metal parts.

●Never attempt to use the instrument if it′

s surface or

your hand are wet.

●Do not exceed the maximum allowable input of any

measuring range.

WARNING

●Never attempt to make any measurement, if any

abnormal conditions are noted, such as broken case,

and exposed metal parts.

●Do not install substitute parts or make any

modification to the instrument. Return the instrument

to the distributor from who you purchased this

instrument for repair or re-calibration in case of

suspected faulty operation.

●Always keep your fingers and hands behind the

barrier on the instrument to avoid the possible shock

hazard.

CAUTION

●Do not step on or pinch the cord to prevent the jacket

of cord from being damaged.

●The output connector shall be removed or connected

without clamping a conductor. Otherwise, it may

cause a failure.

●Do not expose the instrument to direct sunlight, high

temperatures, humidity or dew.

●Never give shocks, such as vibration or drop, which

may damage the instrument.

●Use a damp cloth and detergent for cleaning the

instrument. Do not use abrasives or solvents.

F

∼

Refer to the instructions in the manual.

Indicates a Instrument with double or reinforced

insulation

Indicates that this instrument can clamp on bare

conductors.

Indicates AC

Safety symbols

2. Features

●

This is a clamp sensor for our Power meter.

●

Designed to international safety standard

IEC61010-2-032

CAT. III Pollution Degree 2

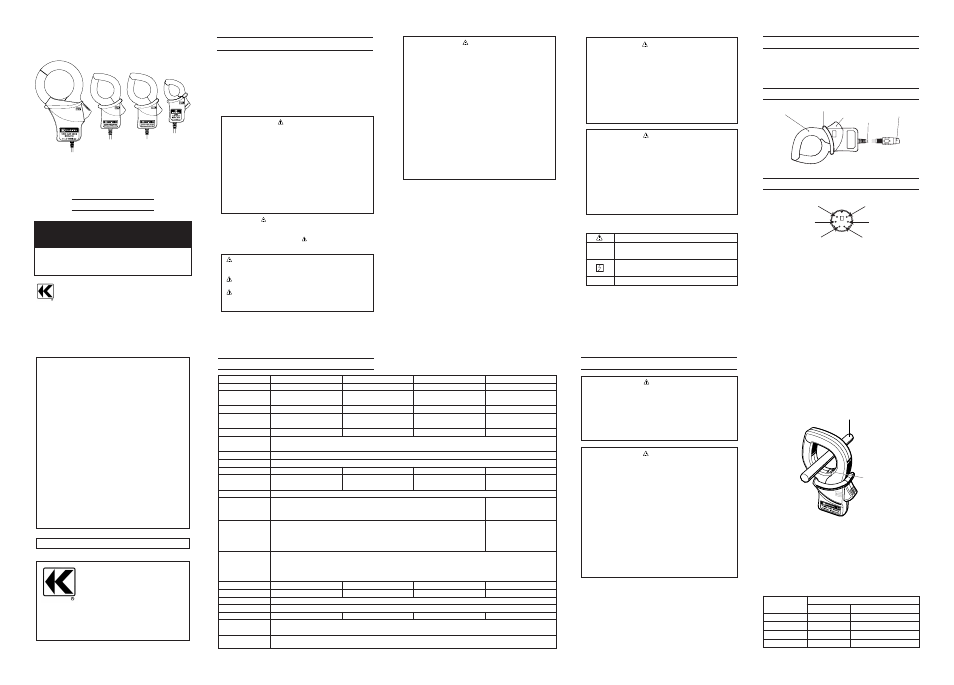

3. Instrument layout

4. Din plug pin assignment

3: GND pin

5: Output signal pin

1, 2, 4 and 6: No use

*Above figure shows the pin assignment seeing the

Clamp sensor from output connector part. The figure

of the pin assignment of connection terminal is

symmetrical to above figure.

Transform Jaws

Barrier

Trigger

Cable

Output connector

5

3

1

2

4

6

92-1640

04-03

DISTRIBUTOR

KYORITSU ELECTRICAL INSTRUMENTS

WORKS, LTD.

No.5-20, Nakane 2― chome, Meguro-ku,

Tokyo, 152-0031 Japan

Phone:81-3-3723-0131 Fax:81-3-3723-0152

URL:http://www.kew-ltd.co.jp

E-mail:[email protected]

Factories:Uwajima&Ehime

Kyoritsu reserves the rights to change specifications or designs

described in this manual without notice and without obligations.

Model

Rated voltage

Output voltage

Measuring range

Accuracy

(Input: sine wave)

Phase characteristics

Temperature & humidity range

(Guaranteed accuracy)

Operating temperature range

Storage temperature range

Maximum permissible input

Output

impedance

Location for use

Applicable

standards

Withstand

voltage

Insulation

resistance

Conductor Size

Dimension

Cable length

Output terminal

Weight

Accessories

Option

8127

AC100Arms(141Apeak)

AC0∼500mV

(AC500mV/AC100A):5mV/A

AC0∼100A

±0.5%rdg±0.1mV(50/60Hz)

±1.0%rdg±0.2mV(40∼1kHz)

±2deg within(at 1∼100A / 45∼65Hz)

23±5℃, relative humidity: 85% or less (no condensation)

0∼50℃, relative humidity: 85% or less (no condensation)

-20∼60℃, relative humidity: 85% or less (no condensation)

AC100Arms continuous(50/60Hz)

Approx. 11Ω

Altitude up to 2000m, Indoors

IEC 61010-1, IEC 61010-2-032

Measurement CAT. Ⅲ (300Vrms)

Pollution degree 2

IEC 61326

IEC 61010-1, IEC 61010-2-032

Measurement CAT. Ⅲ (600Vrms)

Pollution degree 2

IEC 61326

AC3320Vrms (50/60Hz)for 5 sec.

between Jaw and enclosure

between enclosure and output terminal

between Jaw and output terminal

50MΩ or greater at 1000V

between Jaw and enclosure

between enclosure and output terminal

between Jaw and output terminal

AC5350Vrms (50/60Hz)for 5 sec.

between Jaw and enclosure

between enclosure and output terminal

between Jaw and output terminal

Approx. 5Ω

Approx. 2Ω

Approx. 1Ω

AC200Arms continuous (50/60Hz)

AC500Arms continuous (50/60Hz)

AC1000Arms continuous (50/60Hz)

±1deg within(at 2∼200A / 45∼65Hz)

±1deg within(at 5∼500A / 45∼65Hz)

±1deg within(at 10∼1000A / 45∼65Hz)

±0.5%rdg±0.1mV(50/60Hz)

±1.0%rdg±0.2mV(40∼1kHz)

±0.5%rdg±0.1mV(50/60Hz)

±1.0%rdg±0.2mV(40∼1kHz)

±0.5%rdg±0.2mV(50/60Hz)

±1.5%rdg±0.4mV(40∼1kHz)

AC0∼200A

AC0∼500A

AC0∼1000A

AC0∼500mV

(AC500mV/AC200A):2.5mV/A

AC0∼500mV

(AC500mV/AC500A):1mV/A

AC0∼500mV

(AC500mV/AC1000A):0.5mV/A

AC200Arms(283Apeak)

AC500Arms(707Apeak)

AC1000Arms(1414Apeak)

8126

8125

8124

5. Specifications

Approx.24mm in diameter (max.)

100(L)×60(W)×26(D)㎜

Approx. 3m

MINI DIN 6PIN

Approx. 160g

Instruction manual

Cable marker

MODEL 7146(Banans Φ4 adjuster plug)

MODEL 7147(Extension cable)

Approx. 260g

Approx. 260g

Approx. 510g

128(L)×81(W)×36(D)㎜

128(L)×81(W)×36(D)㎜

186(L)×129(W)×53(D)㎜

Approx.40mm in diameter (max.)

Approx.40mm in diameter (max.)

Approx.68mm in diameter (max.)

6. Operating instructions

DANGER

●Never make measurement on a circuit in which the

electrical potential exceeds AC300V using MODEL8127

and AC600V using MODEL8124, 8125 and 8126 in order

to avoid possible shock hazard.

●The transformer jaws are made of metal and their tips

are not completely insulated. Be especially careful

about the possible shorting where the measured object

has exposed metal parts.

CAUTION

●Take sufficient care to avoid shock, vibration or

excessive force when handling the instrument.

Otherwise, precisely adjusted transformer jaws will be

damaged.

●When transformer jaws do not fully close, never try to

close them by force, but make them free to move and

try again. If a foreign substance is stuck in the jaw

tips, remove it.

●When making current measurements, keep the

transformer jaws fully closed.

Otherwise, accurate measurements cannot be taken.

Maximum conductor size is as follows.

MODEL8124 : 68mm in diameter

MODEL8125/ 8126: 40mm in diameter

MODEL8127 : 24mm in diameter

●Hold the inserting part (except for the cable) and

disconnect the Output connector from the measuring

instrument so as not to cause a break in the cord.

6-1 Measurement procedures

(1) Connect the Output connector to the Input terminal of

the measuring instrument.

(2) Press the Trigger to open the transformer jaws and

clamp onto one conductor.

In this case, the measured conductor shall be at the center

of the jaws.

When connecting a sensor with a Power meter (our

Power meter, MODEL6300, etc.) match the arrow mark

Conductor

Load

Current direction

arrow

Power

source

6-2 Setting for MODEL6300 Power meter

Refer to the table below when using these clamp

sensors with MODEL6300, It shows the settings for

clamp sensor and available current ranges on

MODEL6300.

For further details on the settings, see the

instruction manual for MODEL6300.

MODEL

Setting for MODEL6300

Type of Clamp sensor

Current range

10/20/50/100A

20/50/100/200A

50/100/200/500A

100/200/500/1000A

100A

200A

500A

1000A

MODEL8127

MODEL8126

MODEL8125

MODEL8124

(Power source to load), which is indicated on the

transformer jaws, with the current flowing direction in

order to synchronize the phases of measured current

and output voltage.

(3) Ensure that the tips of transformer jaws are firmly

closed.