KROHNE DK 700 EN User Manual

Miniature flowmeters, For analytical process, Dk 700

4000666201

KROHNE 08/2009

Installation

and

Miniature flowmeters

Operating Instructions

for analytical process

DK 700

Installation

Ensure materials compatibility

The temperature of the product and the allowable operating

pressure must not exceed the specified maximum values

(see Technical Data).

The measuring section is also permitted to be filled with

flammable liquids, provided a potentially explosive

atmosphere is not permanently or for prolonged periods

present in the measuring tube.

The calculation of the pressurized parts is effected with

allowance for corrosion, erosion through abrasion or

cavitation.

Installation in the pipeline

The variable area flowmeter has to be installed vertically

(float measuring principle - flow direction from bottom to top).

Before installing the flowmeter, blow or flush out the pipeline

leading to the flowmeter.

Use connectors suitable for the flowmeter version. Align the

pipes axially with the bolt holes un the flowmeter without

incurring stresses.

If necessary, support the pipeline on both sides of the

flowmeter to prevent vibration from being transferred to the

flowmeter.

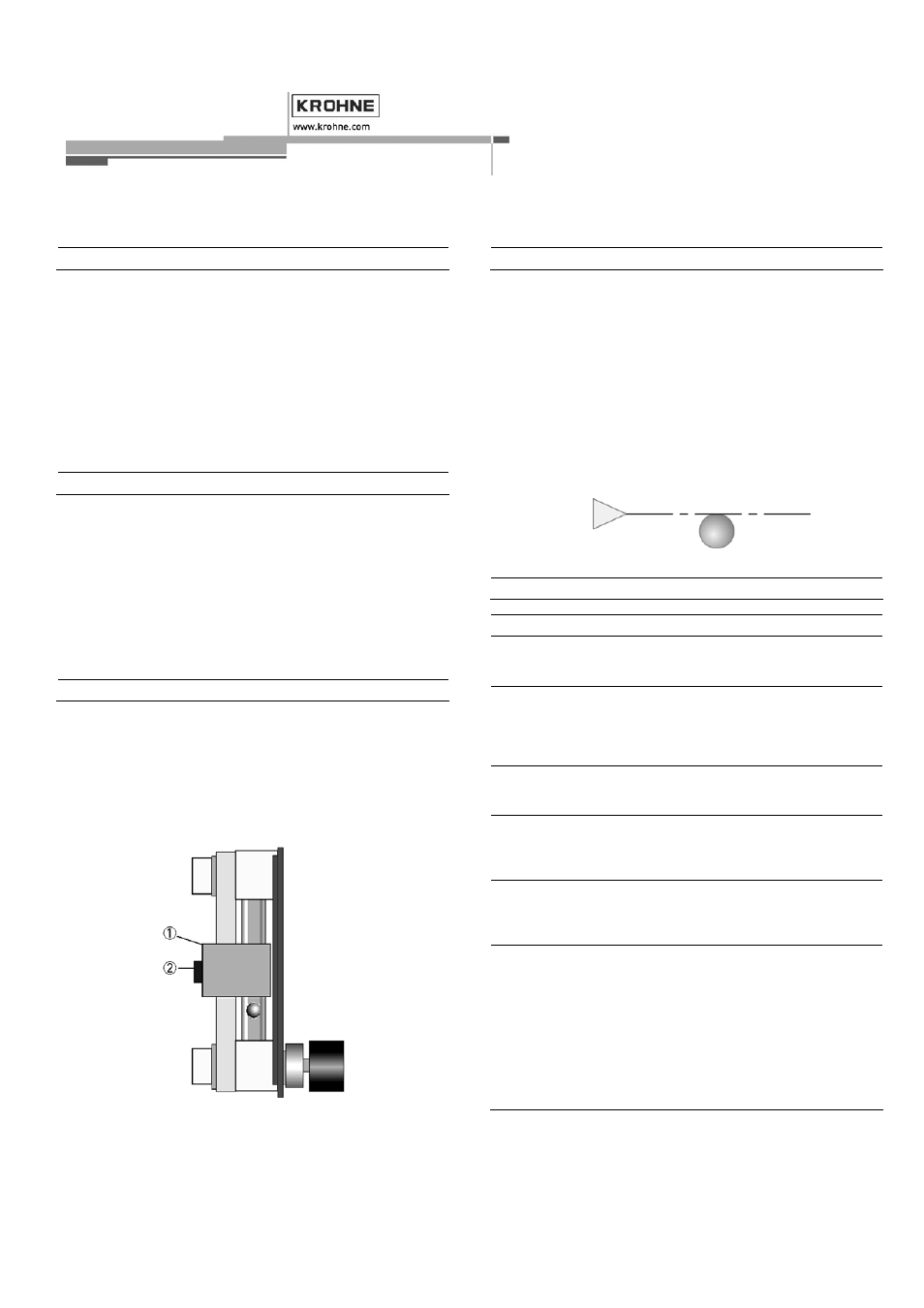

Panel mounting

(see Dimensions and Weights)

Prepare the panel recess as shown in the drawing.

Before installing, remove the clamp clip 1 and

Allen screw 2, 4mm Allen key, from the flowmeter.

Insert flowmeter into recess and align vertically.

Fasten the flowmeter with the clamp clip and Allen screw (4

mm Allen key).

Initial startup

Close needle valve at the flowmeter.

Open shutoff valves upstream and downstream of flowmeter.

Slowly open needle valve and set the desired flowrate.

Where liquids are involved, carefully vent the pipeline to

avoid water hammer that may cause breakage of the glass

cone.

On gas service, increase pressure slowly up to the operating

pressure. Make sure the float does not accelerate to the

upper stop (e.g. in conjunction with solenoid valves) as this

may damage the flowmeter.

The flowrate value is read off from the top edge of the float

(ball).

Reading line

Technical Data

Measuring ranges see Flow table

Accuracy

to VDI/VDE Code 3513, Sh. 2 (q

G

= 50%)

DK 701

6%

DK 702

4%

Measuring cone

Type NG

50

Length 60mm

(2.36")

Scale division

flow units

Float shape

ball

Operating data

Max. allowable op. pressure

4 bar

Max. product temperature

100°C

Connection

Standard G

1/8

Option

tube connection 6 mm

Fitting dimension

75 mm

Diameter of needle valve

Flow ranges

< 5 l/h water, ≤ 100 l/h air

1,0 mm

> 5 l/h water, > 100 l/h air

2,5 mm

Materials

Measuring cone

Borosilicate glass

Float

Stainless steel 1.4401, glass

Gaskets

Standard

FKM / PTFE

Option

FFKM / PTFE

Valve spindle

Stainless steel 1.4571 (316 Ti)

Mount

Rail Aluminium

anodized

Front plate

Polycarbonat

Top and bottom blocks

PVDF