Technical data, 2 counter flanges – KROHNE BATCHFLUX 5500 C Quickstart EN User Manual

Page 18

4

TECHNICAL DATA

18

BATCHFLUX 5500 C

www.krohne.com

05/2014 - 4003386301 - QS BATCHFLUX 5500 R03 en

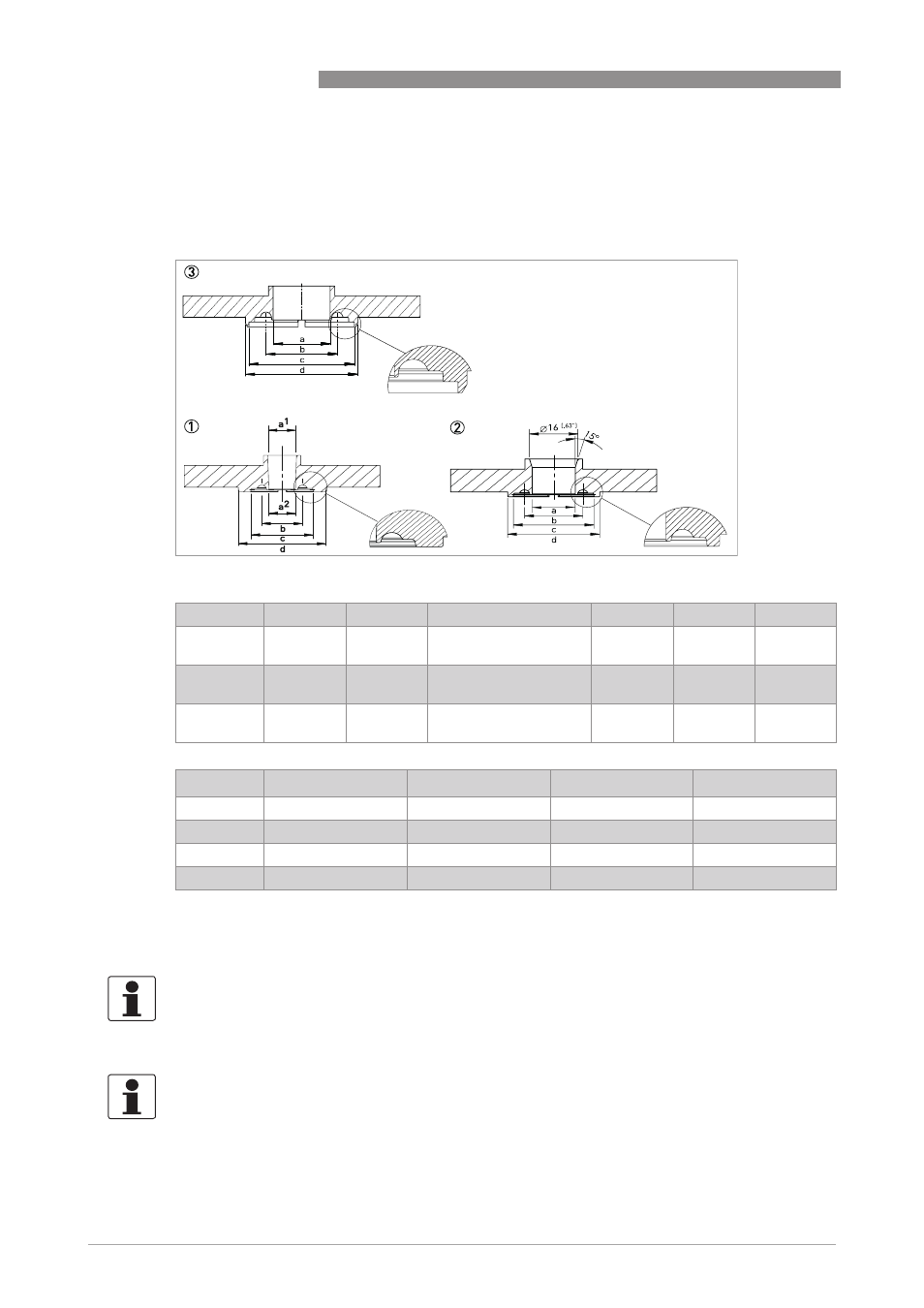

4.2 Counter Flanges

The BATCHFLUX 5500 can be mounted between various types of counter flanges.

Sizes of flanges

Note; flanges must be fully welded and surface roughness, grinded and polished ( roughness

0,8). See for more information the 3A CCE 2007-2 Coordination Bulletin.

DN

a [mm]

b [mm]

c [mm]

d [mm]

O-ring

Flange 1

2,5...10

* see table

below

* see table below

* see table

below

Ø 30.4

Special L-

ring

Flange 2

15

Ш 14.2

Ш 19.2

Ш 26.6

Ш 30.4

15.47 *

3.53

Flange 3

25

Ш 25

Ш 31.3

Ш 41.2

Ш 49.2

15.47 *

3.53

Size DN

a

1

[mm]

a

2

[mm]

b [mm]

c [mm]

2,5

Ш 10

Ш 6.2

Ш 11.1

Ш 18.4

4

Ш 10

Ш 7.2

Ш 12.1

Ш 19.4

6

Ш 10

Ш 9.2

Ш 14.2

Ш 21.5

10

Ш 10

Ш 10.7

Ш 15.7

Ш 23

INFORMATION!

The O-rings require periodic inspection and replacement. As the interval depends on process-

specific variables, the length of the interval cannot be specified.

The O-rings are not part of the portfolio of KROHNE.

INFORMATION!

For 3A applications, O-rings must conform to the requirements of the 3A sanitary standard for

Flow meters, number 28-04 Class I or Class II (max. 8% milk fat).

The used O-rings must also withstand the processing, sterilization and chemical conditions for

the intended use ( for more information, contact the manufacturer)