Warning – Detcon FP-700 SIL 2 Safety Manual User Manual

Page 4

11

OPERATION, MAINTENANCE, INSPECTION AND PROOF TESTING

All normal installation, start-up, and full field calibration recommendations as documented in the FP-700 instruction

manual are applicable to the Safety Certified FP-700 gas detector.

Safety – Certified FP-700 gas detectors require additional Proof Testing to be performed in all cases.

Personnel performing Proof Test procedures shall be competent to perform the task. All proof test results must be

recorded and analyzed. Any corrective actions taken must be documented in the event that an error is found in the safety

functionality. The proof tests must be performed at a frequency as shown in Table 1.

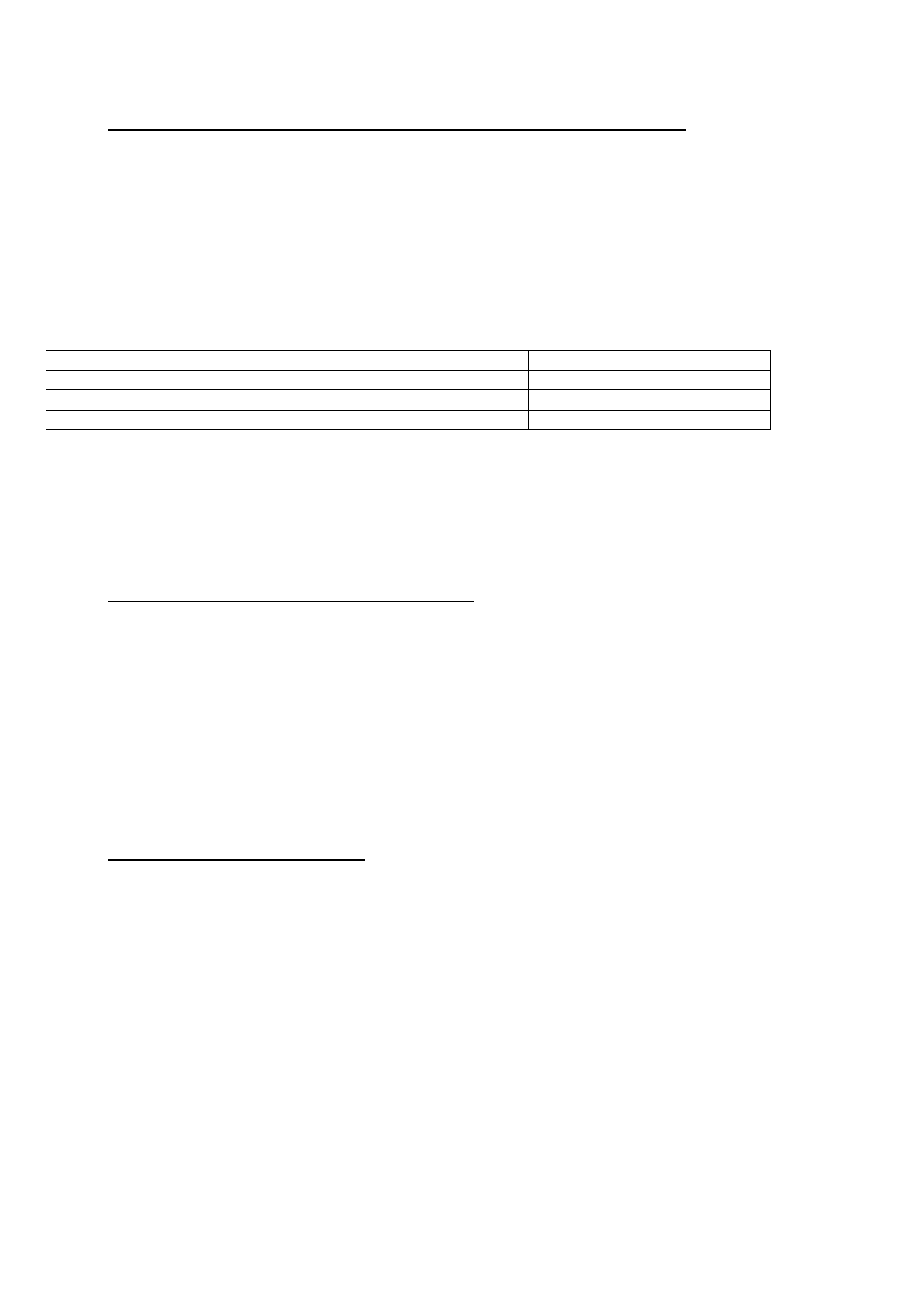

Table 1: Frequency for Performing Proof Tests

FP-700 Proof Test Name

Commissioning

Frequency per year

Visual Field Inspection Proof Test

Yes

2

Gas Response Proof Test

Yes

2

Output Response Proof Test

Yes

1

Warning:

Failure to perform the specified testing and inspection may lower or void the SIL rating for the product or

system.

12

VISUAL FIELD INSPECTION PROOF TEST

Tools Required: Programming magnet

Visual inspection of all Safety-Certified FP-700 Gas Detectors shall be conducted semi-annually to confirm that no

external blockage of gas/vapor path into the sensing chamber exists, ex. debris, trash, snow, mud, external equipment, etc.

Corrective action shall include removal of such impediments should they exist. All gas detectors must be inspected to

ensure that they are capable of providing expected performance and protection. The Model FP-700 provides a scrolling

LED display that indicates fault messages when operational parameters are abnormal. A momentary magnetic swipe

across either programming magnet will visually indicate any scrolling Fault Messages should any be present.

Completion of Visual Field Inspection Proof test will be recorded and documented in the SIS logbook.

13

GAS RESPONSE PROOF TEST

Tools Required:

50% LEL Span Calibration Gas Cylinder (containing 2.50 % volume methane /balance Air or N2 )

Calibration Kit provided by Detcon

This proof test, commonly referred to as a “gas bump test”, requires application of high accuracy compressed calibration

gas to the detector while in NORMAL operational mode and inspecting the 4-20 mA signal output level to ensure that the

signal output is accurately indicative of the applied test gas concentration.

Warning:

Any external alarm equipment, systems or signaling devices that could be automatically initiated by

performing this test must be disabled or bypassed before performing this test!

When test gas is flowing into the detector, inspection of proper analog signal level output can be made by reading the

analog signal output displayed on the control device. The criteria used for inspection pass is a stabilized response signal