DeFelsko PosiTest AT v.4.0 User Manual

Page 6

Page 7

3.

Close the pressure relief valve on the pump completely. (turn clockwise)

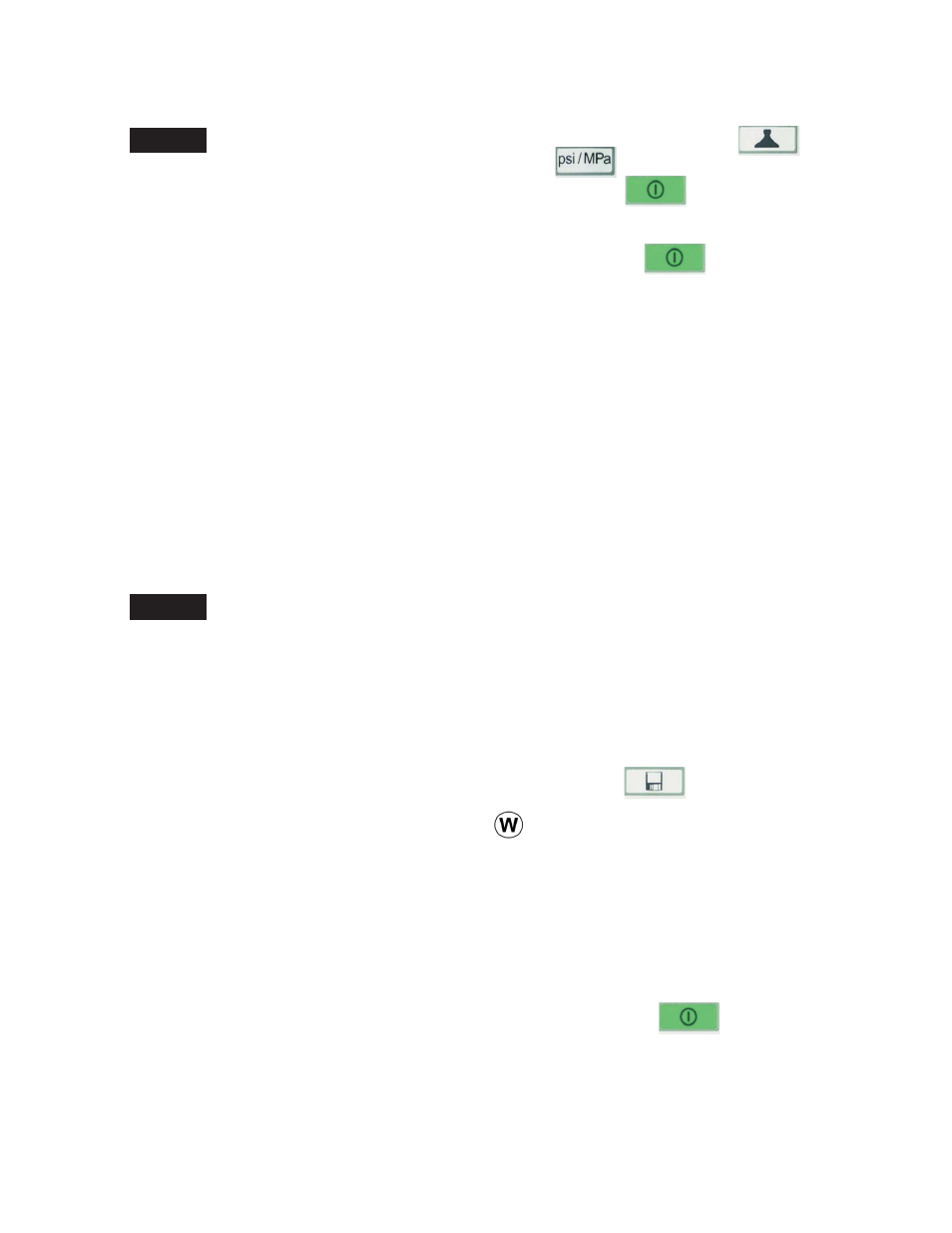

As required, verify and adjust the dolly size by pressing the

button. Select the pressure units by pressing the button. The

instrument will maintain these adjustments even after the button is

pressed.

4.

Zero the instrument BEFORE pumping by pressing the button. This

prepares the instrument for the test by clearing the display, and zeroing the

instrument.

5.

Prime the pump slowly until the displayed reading approaches the priming

pressure. The priming pressure is the point that the instrument begins calculating

and displaying the pull rate. It is also the pressure at which the ability to store

readings is enabled. Priming pressures for the various dolly diameters are:

10 mm

400 psi

2.8 MPa

14 mm

200 psi

1.4 MPa

20 mm

100 psi

0.7 MPa

50 mm

50 psi

0.4 MPa

For optimum results, prior to exceeding the priming pressure, return the

pump handle to its full upright position and then complete a single stroke at the

desired pull rate until the actuator separates the dolly from the coating.

6.

Open the pressure relief valve and remove the dolly from the actuator

assembly.

7.

Readings may be stored into memory by pressing the button (pg. 10).

NOTE:

Troubleshooting (PosiTest AT-M)

Digital display “freezes” at a low value

The Tester uses a sudden drop in actuator pressure as an indication that the dolly

has been pulled from the surface. The test stops and the highest pressure

remains on the display for easy viewing and recording. Pumping up pressure too

quickly at the beginning of a test can cause a sudden pressure pulse, fooling the

Tester into thinking the test is complete. If this happens, restart the test by

opening the pressure relief valve, closing it, then pressing the button. For

more information, see Step 5 above.

NOTE: