Step 3: test area separation – DeFelsko PosiTest AT v.4.0 User Manual

Page 4

Page 5

3.

Gently push down on the dolly to squeeze out excess adhesive. Do not twist

or slide the dolly back and forth on the coating as air bubbles may be gener-

ated.

4.

Carefully remove excess adhesive from around the edges of the dolly with

included cotton swabs.

5.

Allow to cure per the adhesive manufacturer's instructions

Many adhesives cure faster and provide a stronger bond when cured

with heat. Similarly, cold environments may cause a longer cure time and weak-

er bond strength.

Step 3: Test Area Separation

Step 3: Test Area Separation

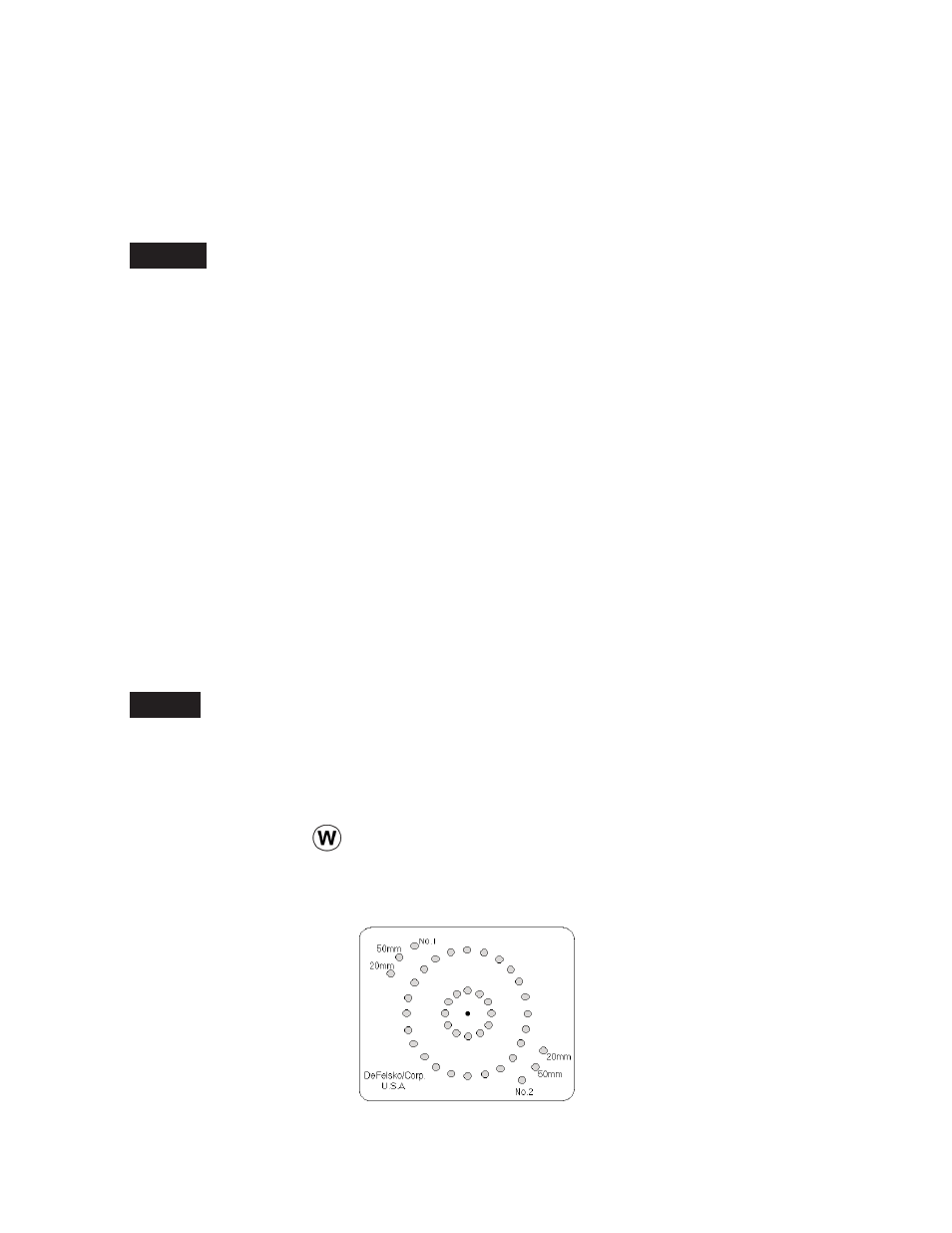

Drilling Template

Cutting Instructions

1.

Cut through the coating around the edges of the dolly with the included cut-

ting tool, removing any excess adhesive.

2.

Clear away any debris from the cutting process.

-

Cutting may induce coating surface flaws such as microcracking that

may alter test results.

-

For coatings with strong lateral bonding it is recommended to cut

completely through the coating down to the substrate.

The decision of when to cut around a dolly is dependent on the standard,

specification or contractual agreement to which the test is to comply. The primary

purpose for cutting through the coating is to isolate a specific diameter test area.

When the decision to cut into the coating has been made, it is recommended to

cut all the way through to the substrate. As a minimum, it is suggested to carefully

cut away excess adhesive from the dolly application process. This typically

prevents a larger area of coating from being pulled away from the substrate,

resulting in a higher pull-off pressure.

When testing very thick coatings, an optional drilling template may be preferred.

NOTE:

NOTE: