Wellsaw 1318-SA User Manual

Page 39

37

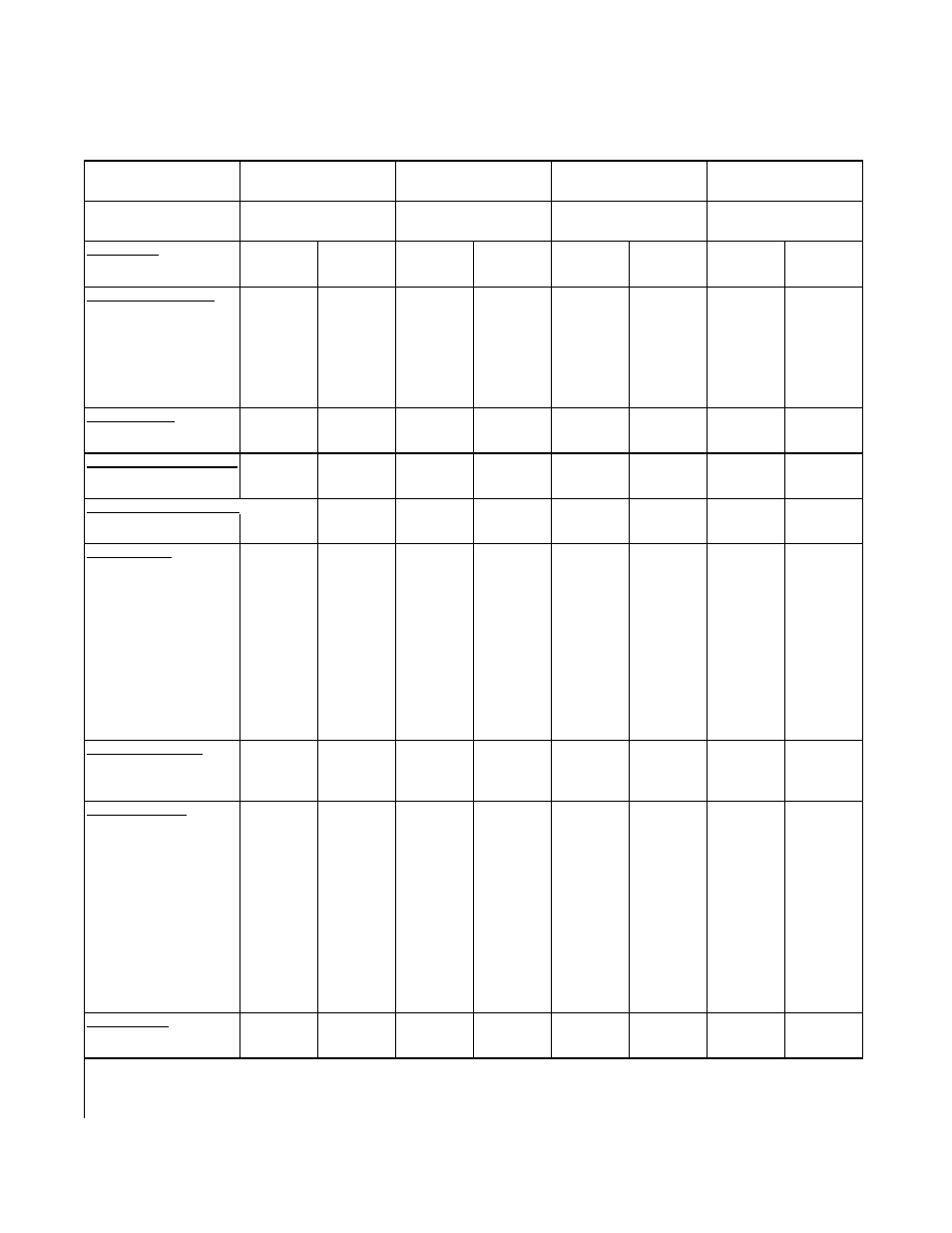

Stock Dimensions

0 - 1"

1" - 3"

3" - 6"

6"+

Tooth Pitch

10/14, 8/12

8/12, 6/10, 5/8

5/8, 4/6, 3/4, 3 Sabre

3/4, 2/3, 2 Sabre,

1 Tooth, 3/4" T.S.

Material (Annealed)

Blade

Cutting

Blade

Cutting

Blade

Cutting

Blade

Cutting

Speed

Rate

Speed

Rate

Speed

Rate

Speed

Rate

(SFPM)

(SIPM)

(SFPM)

(SIPM)

(SFPM)

(SIPM)

(SFPM)

(SIPM)

Silicon Steels

9255-9260

200

2 - 4

180

3 - 5

180

3 - 5

150

3 - 5

9261-9262

200

1 - 3

160

2 - 3

160

2 - 4

150

2 - 3

High Speed Tool Steels

T-1, T-2

130

1 - 2

110

2 - 3

100

2 - 4

90

2 - 3

T-4, T-5

110

1 - 2

100

1 - 2

90

2 - 3

80

1 - 2

T-6, T-8

110

1 - 2

100

1 - 2

80

1 - 2

70

1 - 2

T-15

80

1

80

1

70

1

50

1

M-1

150

1 - 3

140

2 - 4

130

3 - 5

110

2 - 4

M-2, M3

120

1 - 2

110

2 - 3

100

3 - 4

80

2 - 3

M-4, M-10

100

1 - 2

90

1 - 2

80

1 - 3

60

1 - 2

Hot Work Steels

H-12, H-13, H-21

150

2 - 4

125

3 - 5

125

2 - 4

125

2 - 4

H-22, H-24, H-25

150

1 - 3

125

1 - 3

125

1 - 3

125

1 - 3

Shock Resisting Tool Steels

S-1

220

2 - 4

180

3 - 5

165

3 - 5

150

2 - 4

S-2, S-5

170

1 - 3

150

3 - 5

120

2 - 4

100

1 - 3

Special Purpose Tool Steels

L-6

200

2 - 4

180

3 - 5

170

3 - 5

150

2 - 4

L-7

200

2 - 4

180

3 - 5

150

3 - 5

100

2 - 4

Stainless Steels

201, 202, 302, 304

120

2 - 4

100

2 - 4

100

2 - 4

100

1 - 3

303, 303F

140

2 - 4

120

2 - 4

100

3 - 5

100

2 - 4

308, 309, 310, 330

90

1

70

1

60

2

60

1

314, 316, 317

90

1

80

1

70

2

60

1

321, 347

130

1 - 3

110

1 - 3

100

2 - 4

80

1 - 3

410, 420, 420F

150

1 - 3

130

1 - 3

120

2 - 4

100

1 - 3

416, 430F

200

3 - 5

180

4 - 6

170

5 - 7

150

4 - 6

430, 446

100

1 - 3

90

2 - 4

80

2 - 4

80

1 - 3

440 A,B,C

120

1 - 3

10

1 - 3

90

2 - 4

70

1 - 3

440F, 443

150

1 - 3

130

1 - 3

120

2 - 4

100

1 - 3

17-4PH, 17-7PH

100

2 - 3

90

2 - 4

80

3 - 4

80

2 - 3

A-7

100

1 - 2

100

1 - 2

100

2 - 3

100

2 - 3

Beryllium Copper #25

BHN 100-120

350

4 - 6

300

5 - 7

275

6 - 8

225

5 - 7

BHN 220-250

250

2 - 4

225

3 - 5

200

3 - 4

175

3 - 5

BHN 310-340

200

1 - 2

160

1 - 2

140

2 - 3

100

1 - 2

Nickel Base Alloys

Monel

100

1 - 2

100

1 - 2

80

1 - 2

60

1

R Monel

140

2 - 3

140

2 - 4

125

2 - 4

75

2 - 3

K Monel

100

1

80

1

60

1

60

1

KR Monel

100

1 - 3

90

1 - 3

80

1 - 3

60

1 - 2

Inconel

110

1 - 2

100

1 - 3

80

1 - 3

80

1 - 2

Inconel X

90

1

80

1

70

1

60

1

Hastelloy A

120

1 - 2

100

1 - 2

85

2 - 3

75

1 - 2

Hastelloy B

110

0 - 1

100

1 - 2

90

1 - 2

75

0 - 1

Hastelloy C

100

0 - 1

90

0 - 1

70

0 - 1

60

0 - 1

Rene 41

90

1

90

1

90

1 -2

90

1 - 2

Udimit

100

1

90

1 - 2

90

1 - 2

90

1 - 2

Waspalloy

90

1

90

1 - 2

90

1 - 2

90

1 - 2

Titanium

100

1 - 2

100

2 - 3

100

2 - 3

100

2 - 3

Titanium Alloys

TI-4AL-4MO

100

0 - 1

90

0 - 1

80

0 - 1

70

0 - 1

TI-140A2CR-2MO

100

0 - 1

90

0 - 1

80

0 - 1

60

0 - 1